A group of mechanical engineering students from Purdue University designed an efficient, award-winning 3D printable radiator.

The design inspired by shark skin ranked first in the “Virtual Student Radiator Design Challenge”, an American university competition organized by the ASME K-16 Committee and the Institute of Electrical and Electronics Engineers (IEEE). This challenge was also supported and sponsored by the global conglomerate General Electric.

The Heat Sink Design Challenge

The design challenge prompted a team of engineering students with the heat source and size of engineering theory to design a 3D printable heat sink-a device that transfers heat from electronic components to keep them cool. The team was told that they would be judged based on the heat dissipation capacity of their design, the total manufacturing cost, and the number of raw materials required for production.

Soumya Bandyopadhyay, a student of the Purdue University team of Ph.D., stated: “The key to having high-performance electronic devices is to keep them cool. Over the past ten years or so, additive manufacturing has allowed us to provide new advanced cooling solutions Provide innovative designs.”

After the first stage of the competition, the top six teams printed their designs on the GE Additive Concept Laser M2 3D printer with aluminum 3D physically. Then the radiator was tested under controlled conditions at Oregon State University to see if the actual performance of the radiator was comparable to the simulation.

When the dust settled, it was an engineer from Purdue University who was crowned the winner. Their design performance was better than expected, their cost was lower than initially expected, and they even did a good job in minimizing the amount of aluminum used.

Purdue Design

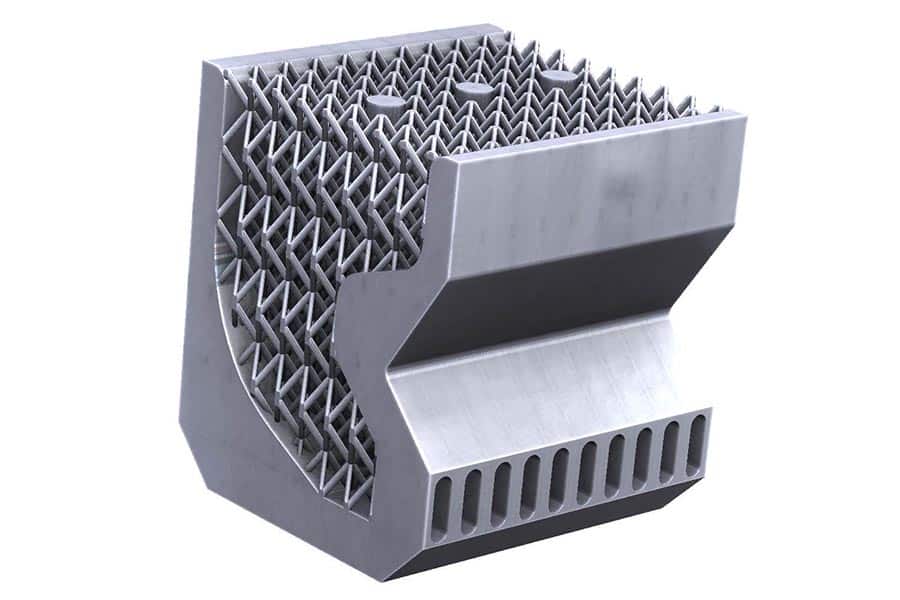

The four engineers from the Purdue University team – Soumya Bandyopadhyay, Julia Meyer, Adeline Naon and Saeel Pai – started their journey in January. After brainstorming with pen and paper a few days ago, the team decided to draw inspiration from nature. At that time, they designed the shark radiator with geometric shapes inspired by shark skin.

Sharkskin has a very unique surface texture. It has millions of tiny spike-like protrusions (called serrations), each of which plays a role in reducing resistance, so the shark can swim with less water resistance. Given that the laws of fluid dynamics apply to liquids and gases, Purdue University engineers added dentin-like shapes to their design walls. This has the effect of reducing pressure drop and causing air mixing.

The engineer also added a vortex generator inspired by Formula One to the front and back of its radiator. These “cyclones” deliberately generate turbulence in the design body, so as to maximize the heat transfer between air particles. Finally, in order to exhaust the hot air from the radiator, the students set up a “breathing area” between the two vortex generators. A respirator is similar to an airbag in a human lung, which absorbs cold air from the surrounding environment and expels the hot air through a perforated ramp.

The heat sink (final design) absorbs cold air and discharges hot air, thereby cooling the electronic components below it. GIF passed Purdue University.

Researchers at the university have previously been studying methods of 3D printing concrete wind turbine parts for offshore use. The ultimate goal of the research is to 3D print concrete anchors, whose cost is only a small part of steel anchors.

The university’s engineers also recently used 3D printing to develop trackable micro-robots. This novel color-based patterning method is expected to make the robot suitable for biomedical applications, such as non-invasive diagnosis and drug delivery, where personal tracking is the key.