3D LifePrints, a UK-based medical 3D printing specialist, has received clearance from the United States Food and Drug Administration (FDA), for their EmbedMed personalized surgery platform.

EmbedMed allows the digitization of the surgical planning process and enables a rapid design process. It also assists in the manufacturing, using 3D printing, of patient-specific medical devices. The FDA (510k) clearance is a further step in the regulatory process that allows the Liverpool-based firm, to (in the words of the FDA) “demonstrate that the device to be marketed is as safe and effective, that is, substantially equivalent, to a legally marketed device.”

The FDA (510k) clearance follows 3D LifePrints’ ISO 13485 medical certification in 2021.

“This clearance is the first step in executing 3D LifePrints’ strategy to bring Personalized Surgery to the US,” said Scott Parazynski, 3D LifePrints US Strategy Director and former NASA astronaut.

“It is our aim for surgeons across the US to have direct access to Personalized Surgical planning and patient-specific devices,” said Henry Pinchbeck, Co-Founder, and Chief Executive Officer. “EmbedMed works at scale; whether you are a hospital looking to set up a Point of Care 3D facility or a surgeon that wants personalized devices for a complex case – our highly qualified bio-medical engineers are here to help.”

Parazynski added, “Our facility at the Texas Medical Center, which enables our engagement with hospitals such as Houston Methodist and MD Anderson will act as the blueprint for a nationwide rollout.”

Features of Surgical Portal – EmbedMed

EmbedMed’s functions consist of processing patient input data through image scan data which serves as a pre-operative software tool. 3D LifePrints software is designed to simplify the surgical planning process. EmbedMed is accessible on mobile phones, computers, and tablets. The platform provides enhanced visualization capabilities that enable clinicians to review and assess many patient cases.

EmbedMed’s in-built analytics enable institutions to learn about improvements in patient outcomes as well as health and operational economics. Medical devices and patient-specific model orders can be placed by clinicians using EmbedMed. It also helps clinicians track their patient’s health progress via EmbedMed.

Manufacturing on Demand

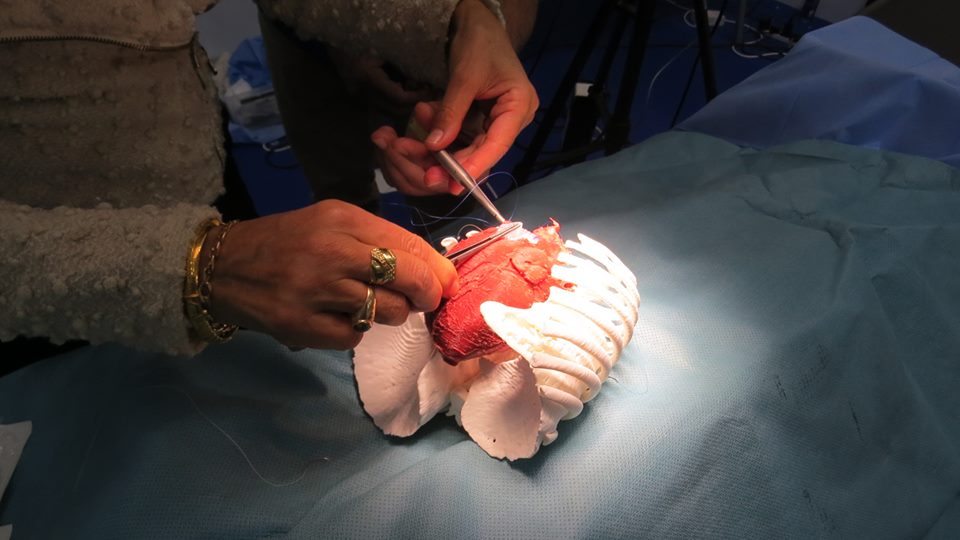

3D LifePrints receives patients’ scans, then digitally plans, and visualizes the surgery through their Cloud Digital Platform (CDP). This is followed by producing and delivering sterilizable surgical guides and anatomical models to hospitals. Patient-specific surgical guides are delivered within 5 days to your doorstep. Cranio-maxillofacial guides and implants are delivered within 3 weeks.

Regulating the medical 3D printing sector

Located under the Department of Health and Human Services, the Food and Drug Administration (FDA or USFDA) is a federal organization. The FDA is in charge of ensuring the safety of food, tobacco products, dietary supplements, prescription and over-the-counter medications, vaccines, biopharmaceuticals, blood transfusions, medical devices, electromagnetic radiation emitting devices (ERED), cosmetics, animal foods & feed, and veterinary products in order to protect and advance public health.

The Federal Food, Drug, and Cosmetic Act (FD&C) is the FDA’s major area of enforcement. The organization also upholds related regulations and other laws, most notably Section 361 of the Public Health Service Act. Previously the FDA released a discussion paper on medical 3D printing.

FDA clearance is a critical milestone necessary for enterprises to access the market. Desktop Health was launched by the US-3D printer manufacturer Desktop Metal in early 2021. The company’s Flexcera Base resin received an FDA (510k) clearance several months later. Elsewhere, FDA clearance was required by ABCorp, for its Additive Manufacturing Center (AMC) in Boston. ABCorp, is a contract manufacturer serving the finance sector that also works in the medical sector. The AMC is registered with the FDA permitting it to serve major medical device production firms handling Class I, II, and some Class III products. Neil Glazebrook, VP of 3D Solutions at ABCorp said, “Additive manufacturing, including 3D printing, offers our clients complete design freedom and is nothing less than transformative for the medical device industry.”

You might also like:

Amnovis produces cost-efficient titanium spinal cages through AM productivity increase: Amnovis is an additive manufacturing production and engineering company based in Aarschot, Belgium. In its AM contract, Amnovis has added process enhancements for manufacturing workflow for titanium implants. This workflow helps produce parts that meet the chemical and medical requirements of the American Society for Testing and Materials (ASTM) standards. This further validates the entire process resulting in increased productivity, both for titanium spinal cages and other medical devices. Ruben Wauthle, CEO and Co-Founder of Amnovis said, “When printing high-end products for quality-critical medical applications, we obtain significantly higher productivity while maintaining superb quality and repeatability.”

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Ada Shaikhnag

Leave A Comment