With the help of 3D printing service provider CRP USA, the micro-satellite manufacturer Mini-Cubes has developed and produced three 3D printed flying PocketQubes.

The satellite is made of carbon fiber-reinforced composite material Windform XT 2.0 using polymer SLS technology. According to Mini-Cubes, it is the first company in the world to use a material type for this specific application-with encouraging results.

The discovery of 3D printing

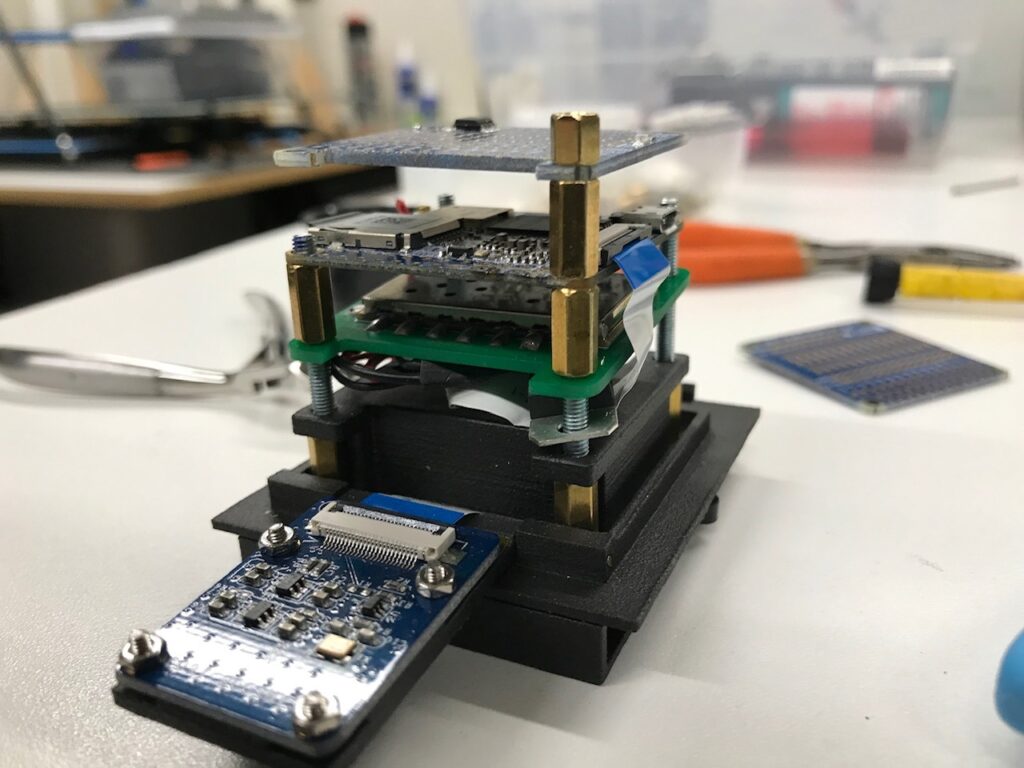

The Mini-Cubes satellite is called Discovery, and its main purpose is to monitor the natural resources on the earth’s surface. This particular project is intended as a proof of concept for the company’s design. Joe Latrell, CEO of Mini-Cubes, first ventured into additive manufacturing a few years ago when he designed a prototype rocket fin for his former aerospace boss. In order to reuse this technology, he turned to CRP USA to 3D print the entire satellite frame.

Latrell explains: “We wanted to include a camera for visual observation, just to see if it could be done. If the process works, we can use the technology to create a constellation of PocketQube satellites just for monitoring a specific resource. In our case, that resource is water.”

Challenges to track

The two main challenges faced during the development phase are miniaturization and material compatibility. In his original idea, Latrell described a satellite with an internal volume of only 50 x 50 x 50mm. Inside its chamber will be a camera, a radio system, and all the electronic equipment needed to monitor the earth hundreds of miles away.

It is not an easy task to manufacture the shell, because a part of the failure means the failure of the entire spacecraft. After extensive discussions with CRP USA, Latrell finally decided to use carbon fiber reinforced Windform XT 2.0, which has achieved a good balance between mechanical properties and printability.

Latrell adds: “The combination of strength and ease of use made the material a natural choice for us. We knew we wanted to use additive manufacturing for Discovery but understood that it would be hard to find something that would work in the harsh environment of space. We discovered Windform® XT 2.0 and after looking at its properties, it was a simple choice.”

Interplanetary test

The project involved the printing of three practical Discovery prototypes. Two are used for testing, and the last one will be sent to orbit. Mini-Cubes claims that these prototypes have passed many tests, such as a 20 kg load test, NASA GEVS-7000 specification vibration test, and vacuum test. PocketQubes can also survive in the temperature range of 50 °C to -40 °C. Latrell plans to test the Discovery in orbit for the first time in the second quarter of 2021.

As private organizations begin to truly understand the nuances of the technology, additive manufacturing of end-use aerospace components has become increasingly popular. Just this month, British aerospace company Orbex announced that its 3D printed rocket will be the first rocket to be launched from the UK’s new spaceport-Sutherland Space Centre. The SLM printing engine runs on liquid oxygen and propane and is designed to be environmentally friendly.

Elsewhere, aerospace company ArianeGroup announced that it has successfully tested the 3D printed rocket combustor. The extensive test round included 14 fire tests conducted on the P8 test bench at the Lampoldshausen test facility at DLR’s German Aerospace Center from May 26 to June 2, 2020.