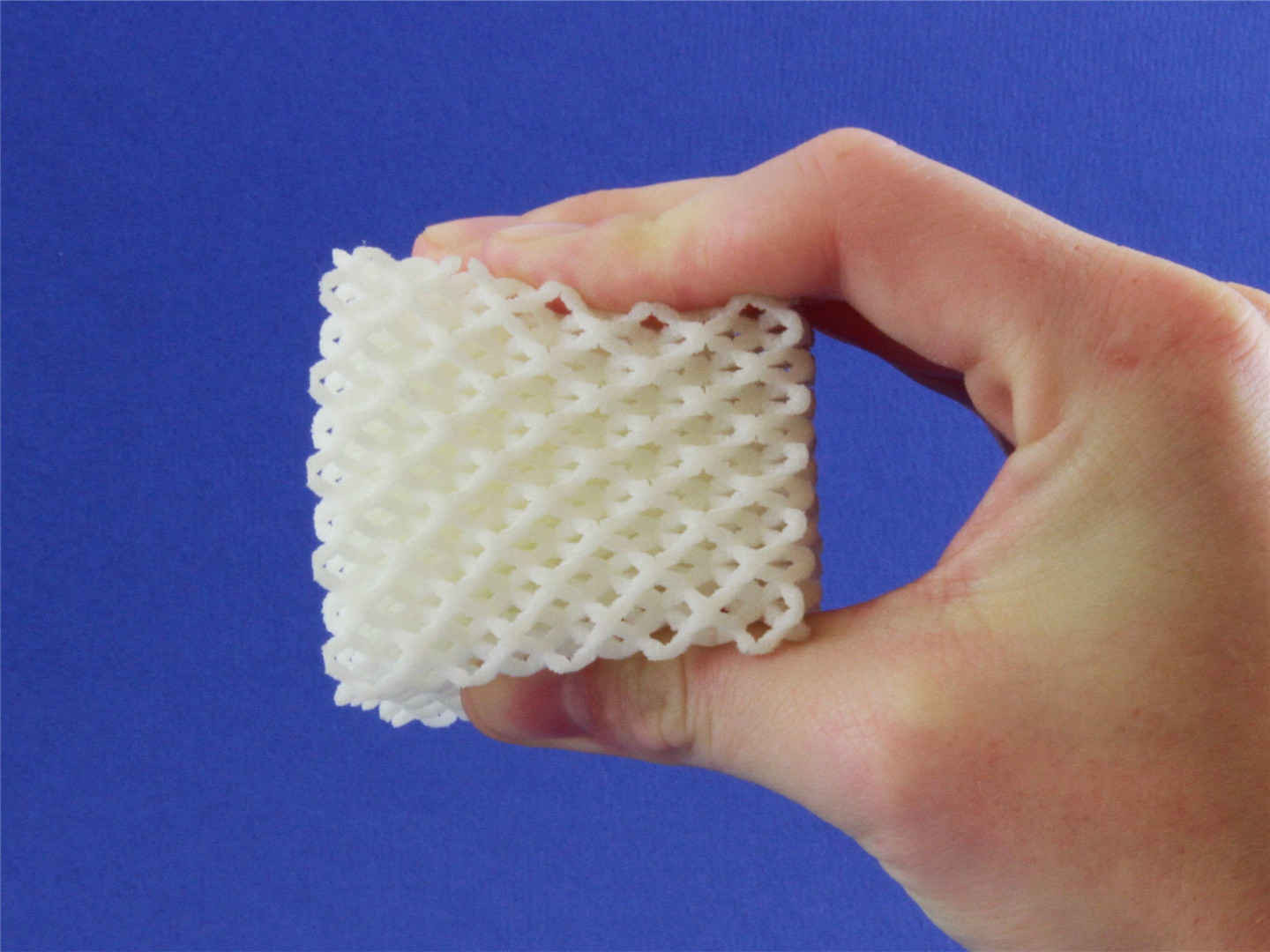

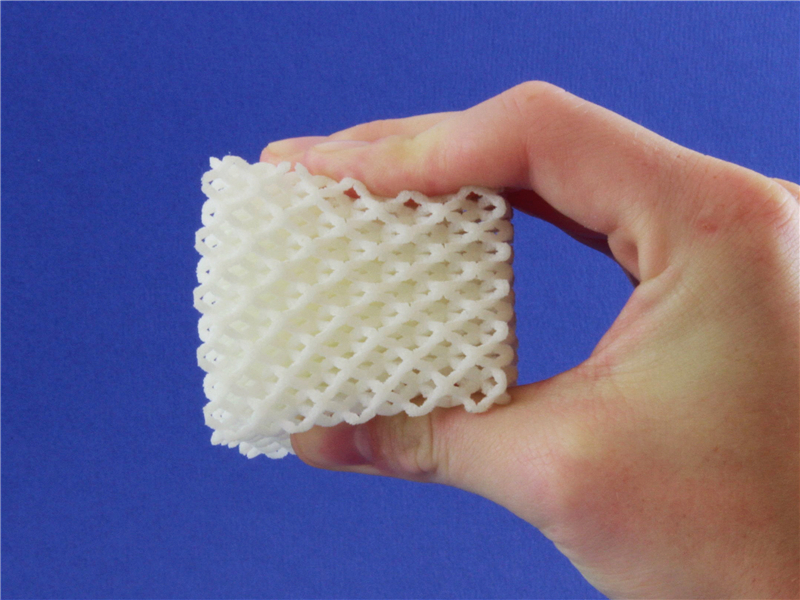

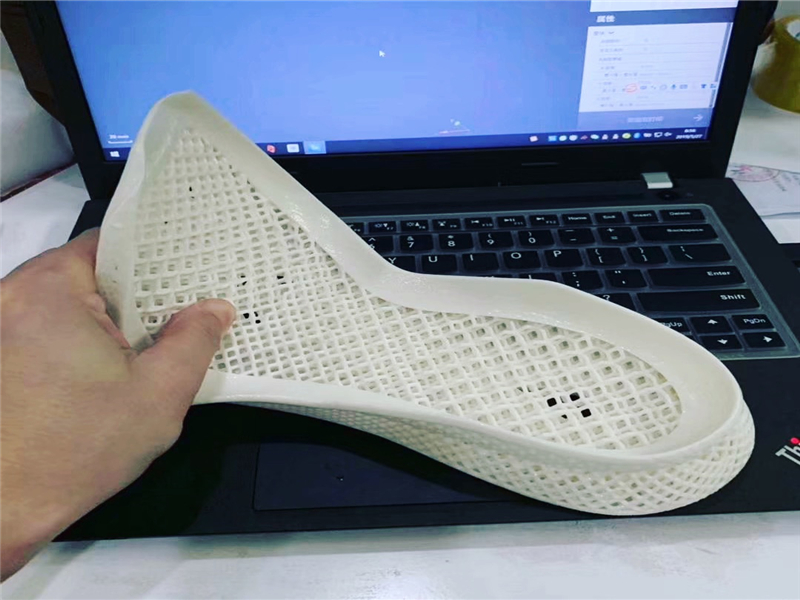

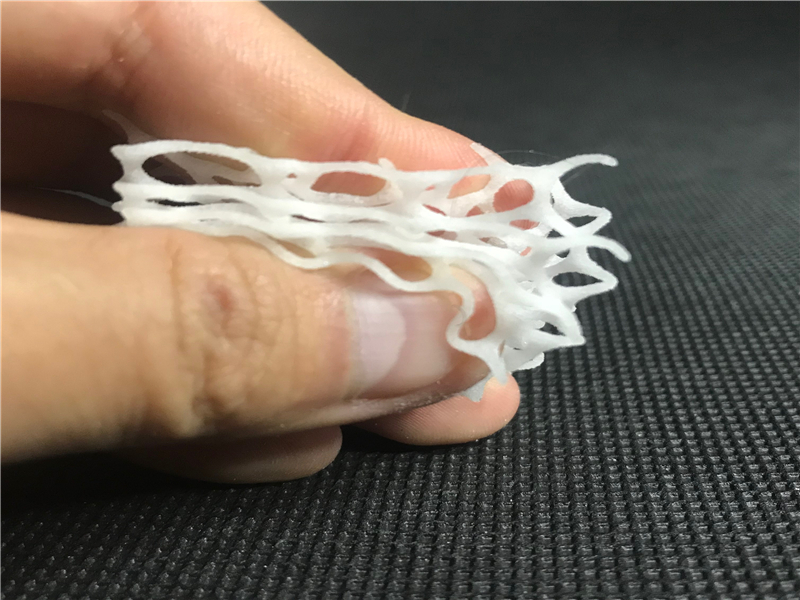

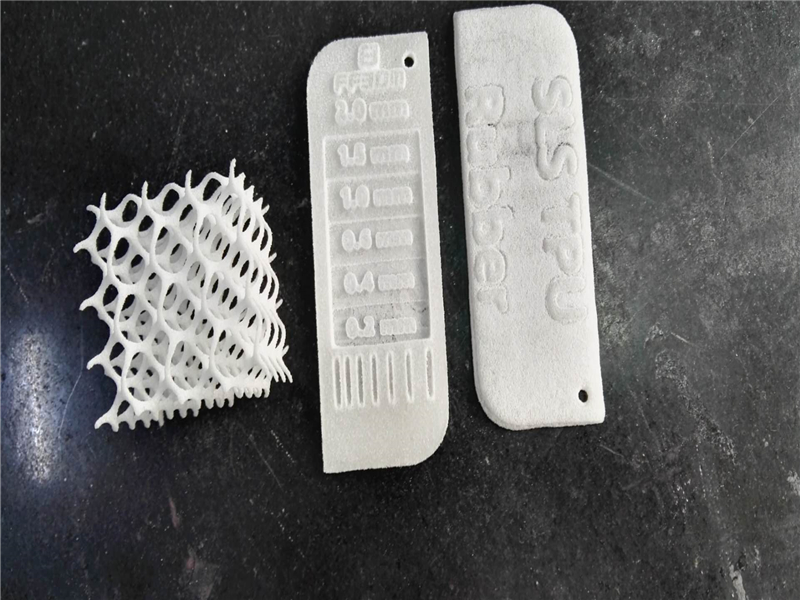

SLS TPU RubberUltrasint TPU 88A Ultrasint TPU 88A is a multi-purpose material for application in Laser Sintering. Parts produced with this material offer a balanced property profile with good flexibility, shock absorption with fine detail. In addition, the material is easy to print, and has good UV and hydrolysis resistance. Max Build Size Min Build Size 5 x 5 x 5 mm Default Layer Height 0.15 mm Optional Layer Heights 0.15 mm Tolerance ┬▒0.5% (with a lower limit of ┬▒0.5 mm) Up to 160 Ōäā Smooth ŌśģŌśģ Detail ŌśģŌśģŌśģ Accuracy ŌśģŌśģŌśģ Rigidity ŌśģŌśģ Flexibility ŌśģŌśģŌśģŌśģŌśģ Available ColorsWhite

Available Post ProcessDyeing

Suitable For Functional prototypes and end products, Not Suitable For Fine-detail models with smooth surfaces, Additional InfoThe molecular bonding pattern of TPU resembles the structure of classic polyurethanes. However, in this case the three-dimensional structure of the cross-linked building blocks is linear. Polymer chains are able to slide off each other. TPUs are thus fusible and can be processed like other thermoplastics. Yet, at the same time, they still possess properties of ŌĆ£classicalŌĆØ polyurethanes. This combination makes them very interesting ŌĆō for laser sintering as well.

Feature

3D PrinterMaterial Spec Sheet

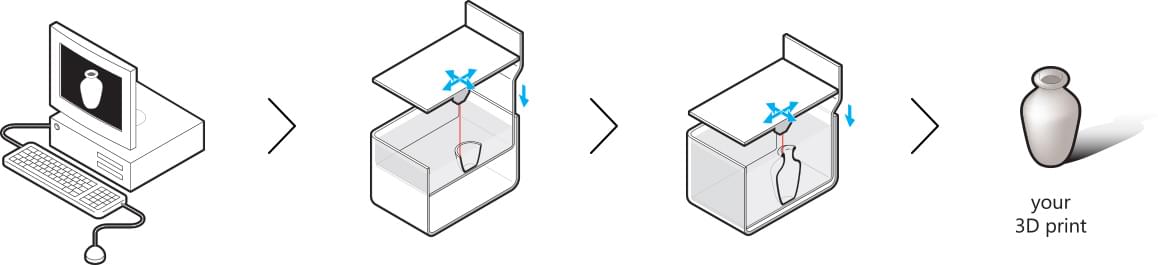

Laser sintering is used to build your design with this material. The models are printed layer by layer by a laser that draws thin lines in the powder, which melts and bonds it together in order to form a thin layer of the model. After a layer is printed, a new layer of fresh powder is spread over the surface by a roller. The printer has a print chamber that is heated to just below the melting point of the powder; the laser beam adds the extra energy to melt the powder, forming a solid model. After a print job is finished, the result is a big block of heated powder with the printed models contained inside.

|