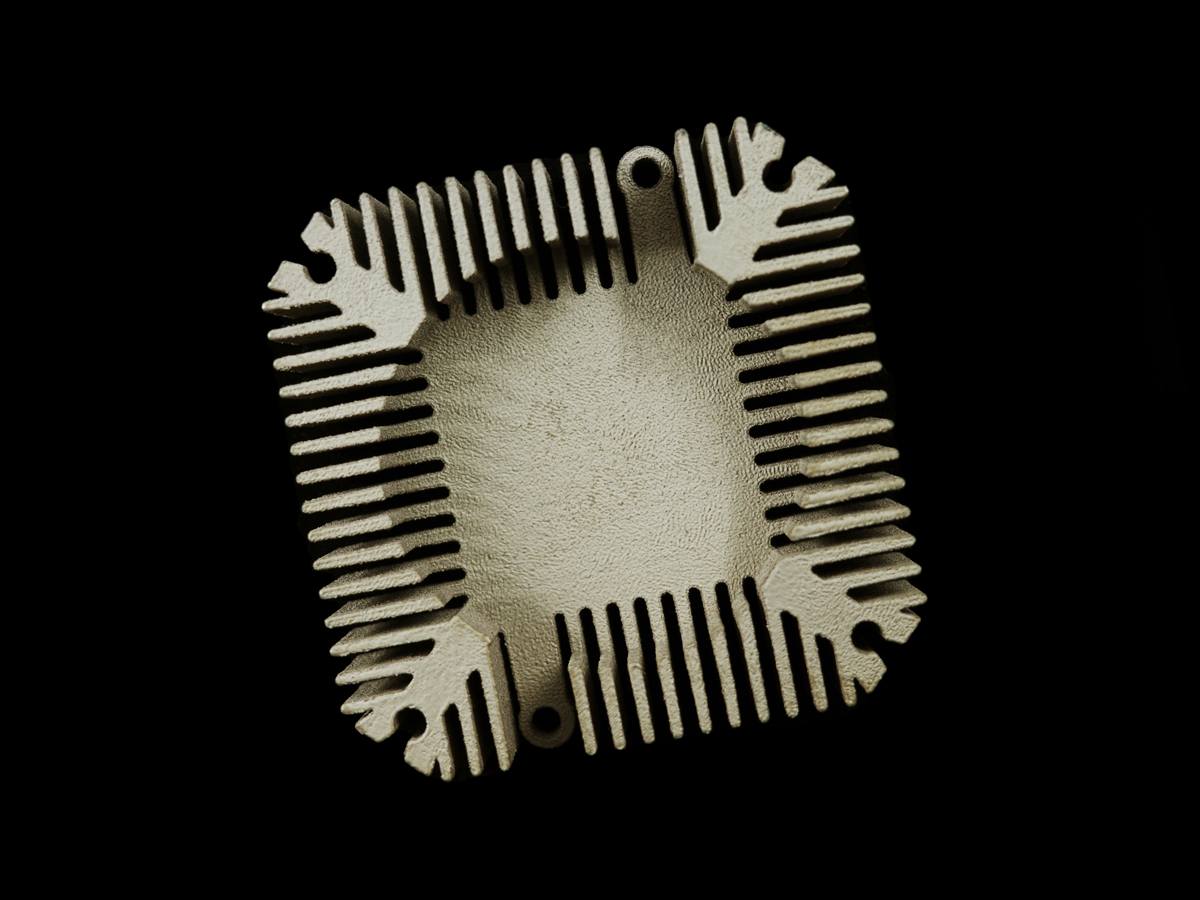

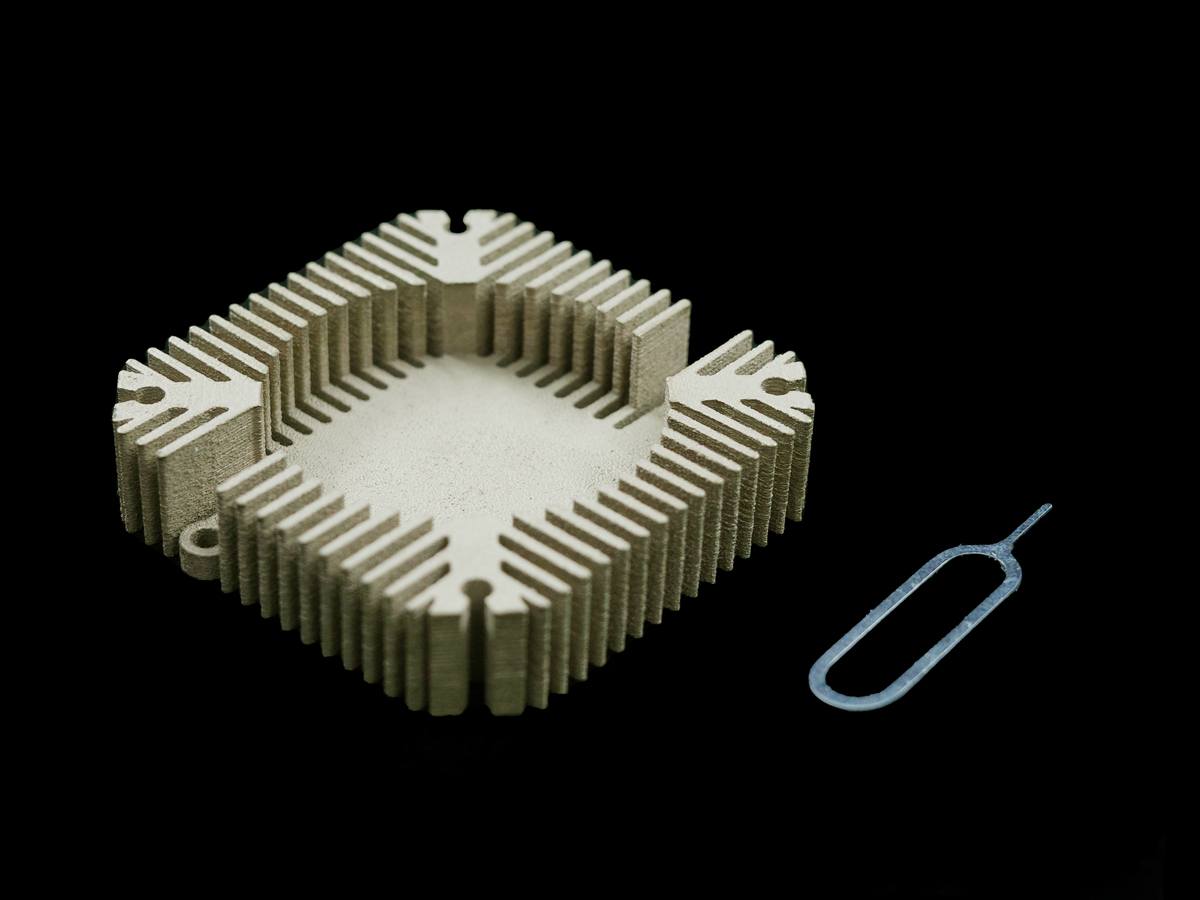

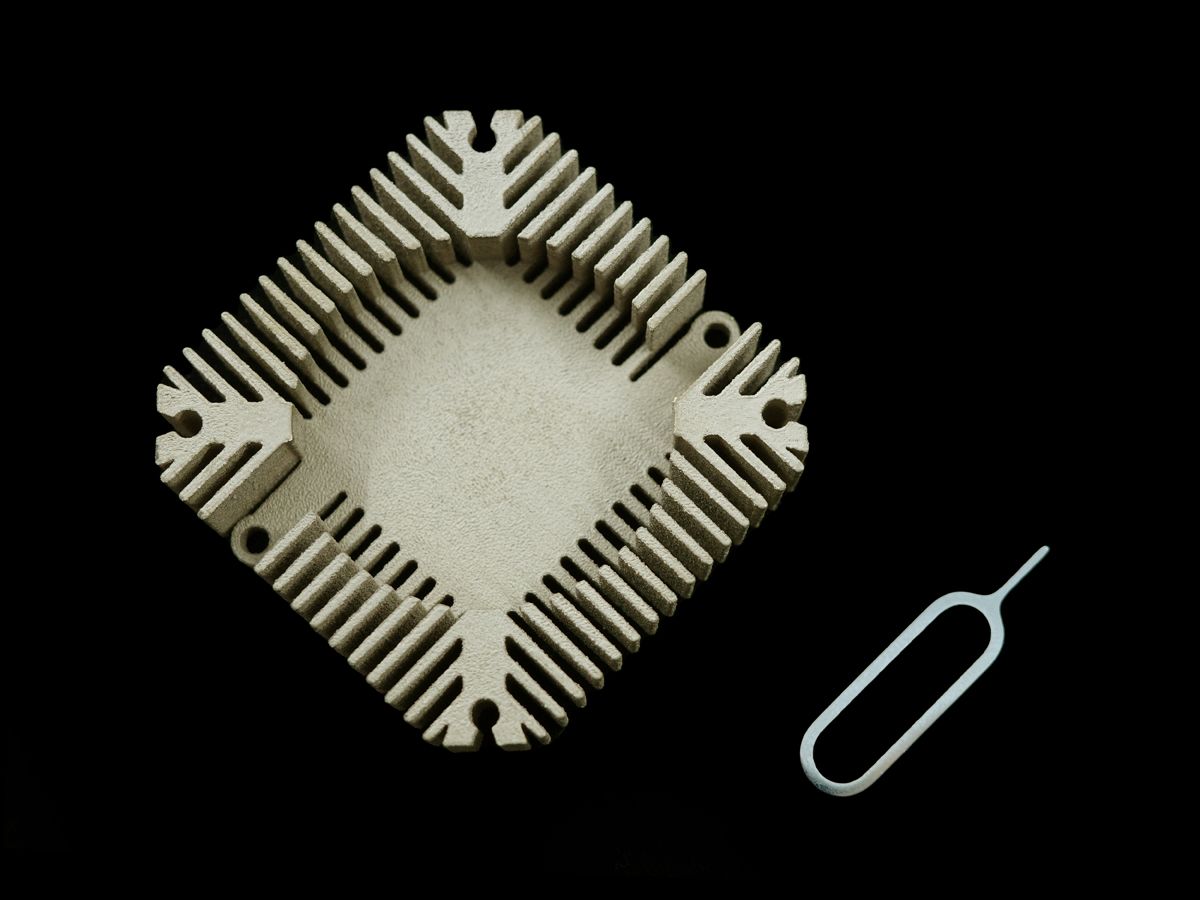

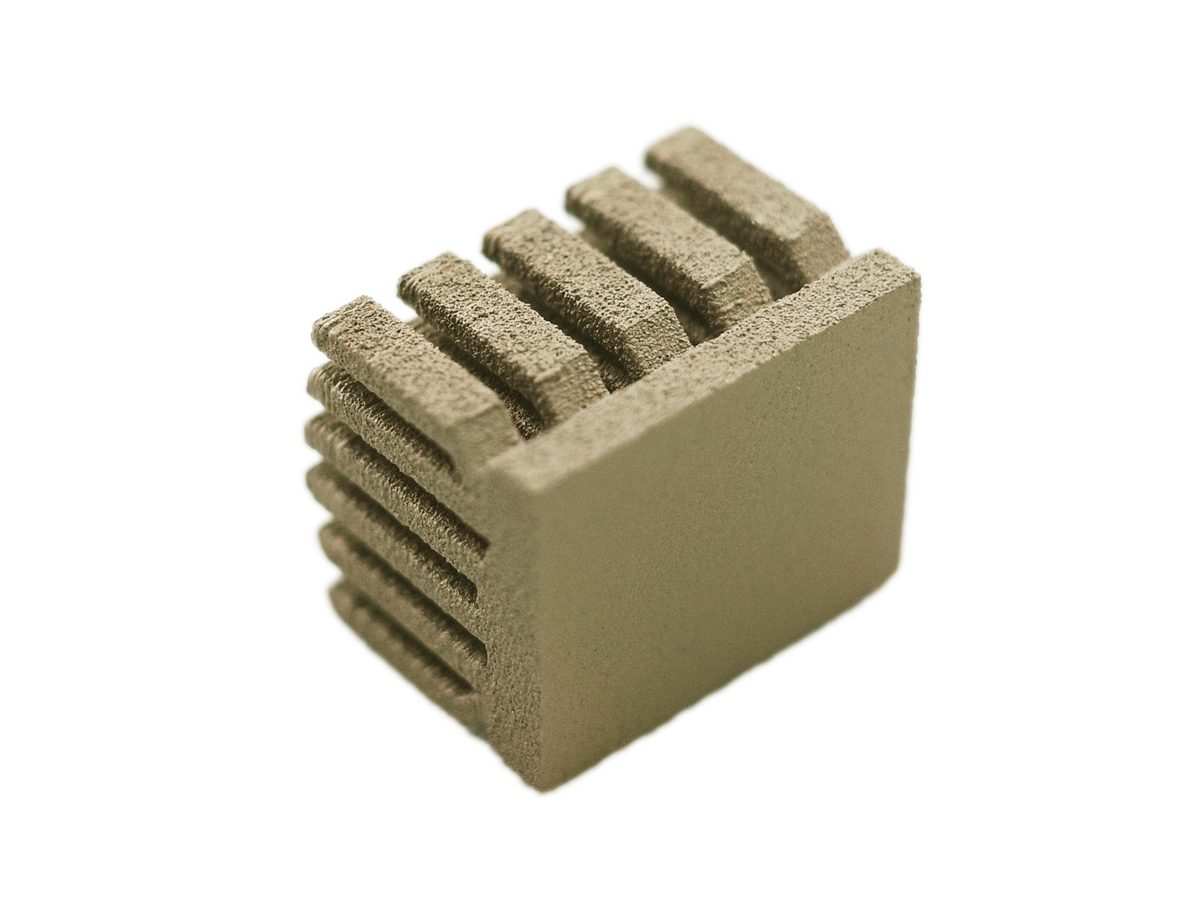

SLM Bronze CuSn10CuSn10 SLM Bronze(CuSn10) material is a popular choice for electrical/thermal/decorative items due to its good thermal conductivity and corrosion resistance. Max Build Size Min Build Size 5 x 5 x 5 mm Default Layer Height 0.05 mm Optional Layer Heights 0.05 mm Tolerance ┬▒0.2% (with a lower limit of ┬▒0.2 mm) N/A Smooth ŌśģŌśģŌśģ Detail ŌśģŌśģŌśģŌśģ Accuracy ŌśģŌśģŌśģ Rigidity ŌśģŌśģŌśģŌśģŌśģ Flexibility ŌśģŌśģŌśģ Available ColorsBronze

Available Post ProcessPolish

, Sandblast

, Anodize

, Electroplate

, Nickel Plate

Suitable For Functional prototypes and end products, Not Suitable For Large models, Additional InfoCuSn10, also known as phosphor bronze or tin bronze, is a versatile copper-tin alloy with a wide range of applications due to its excellent combination of properties. Here are some of the key use cases for CuSn10: ┬Ā 1. Bearings and Bushings: CuSn10’s high wear resistance, strength, and ability to withstand heavy loads make it ideal for bearings and bushings in various machinery. ┬Ā 2. Gears and Worm Wheels: The alloy’s strength and wear resistance are crucial for gears and worm wheels, ensuring reliable power transmission and long service life. ┬Ā 3. Springs and Fasteners: CuSn10’s good elasticity and fatigue strength make it suitable for springs, while its corrosion resistance is beneficial for fasteners in marine or corrosive environments. 4. Marine Applications: CuSn10’s excellent corrosion resistance, especially in saltwater, makes it a popular choice for marine components like propellers, pumps, valves, and fittings. ┬Ā 5. Electrical Components: While not as conductive as pure copper, CuSn10 still offers good electrical conductivity and is used in certain electrical connectors, switches, and contacts. ┬Ā 6. Heat Exchangers: CuSn10’s good thermal conductivity and corrosion resistance make it suitable for heat exchangers in various applications. ┬Ā 7. Decorative Items: The alloy’s attractive bronze color and good workability make it suitable for decorative items, sculptures, and architectural hardware. ┬Ā 8. Other Applications: CuSn10 is also used in musical instruments, plumbing fittings, and various other industrial components where its combination of properties is advantageous. Key Properties of CuSn10 that make it suitable for these applications: CuSn10 offers excellent mechanical properties, allowing it to withstand heavy loads and wear. ┬Ā It resists corrosion in various environments, including saltwater, making it suitable for marine and outdoor applications. ┬Ā CuSn10 can withstand friction and wear, making it ideal for moving parts like bearings and gears. ┬Ā While not as high as pure copper, CuSn10 still offers decent conductivity for certain electrical and thermal applications. ┬Ā It can be easily cast, forged, and machined, allowing for the production of complex shapes. ┬Ā Its excellent combination of mechanical, corrosion, and wear properties makes it a preferred choice for demanding applications where durability and performance are critical.applied to most materials), this cost vanishes when the price is higher than the minimum price. Raw bronze is a high-detail metal with a deep red color similar to rose gold. It has a subtle marbling effect, and the silvery highlights give each piece their own unique character. Polished bronze goes through extensive hand polishing to give it a smooth, glossy finish. It is great for miniatures, precious objects, and shiny, modern jewelry. Raw Bronze has a rustic matte look with rough surfaces. It is great for antique-looking objects, vintage and steampunk jewelry, functional parts, and jewelry prototypes. Some detail is lost during polishing and plating Polishing and plating give this material a beautiful finish, but can have an impact on fine details. During the polishing step, fine or sharp-edged details may be polished down or even broken off. During plating, intricate engravings or holes may be filled in partially or completely. Keep this in mind when you’re designing fine details. Internal detail can not be polished We can only polish well-reachable surfaces, so tight internal spaces may remain unpolished and show slightly uneven plating. Avoid long unsupported stone holding prongs

Feature

3D PrinterMaterial Spec Sheet

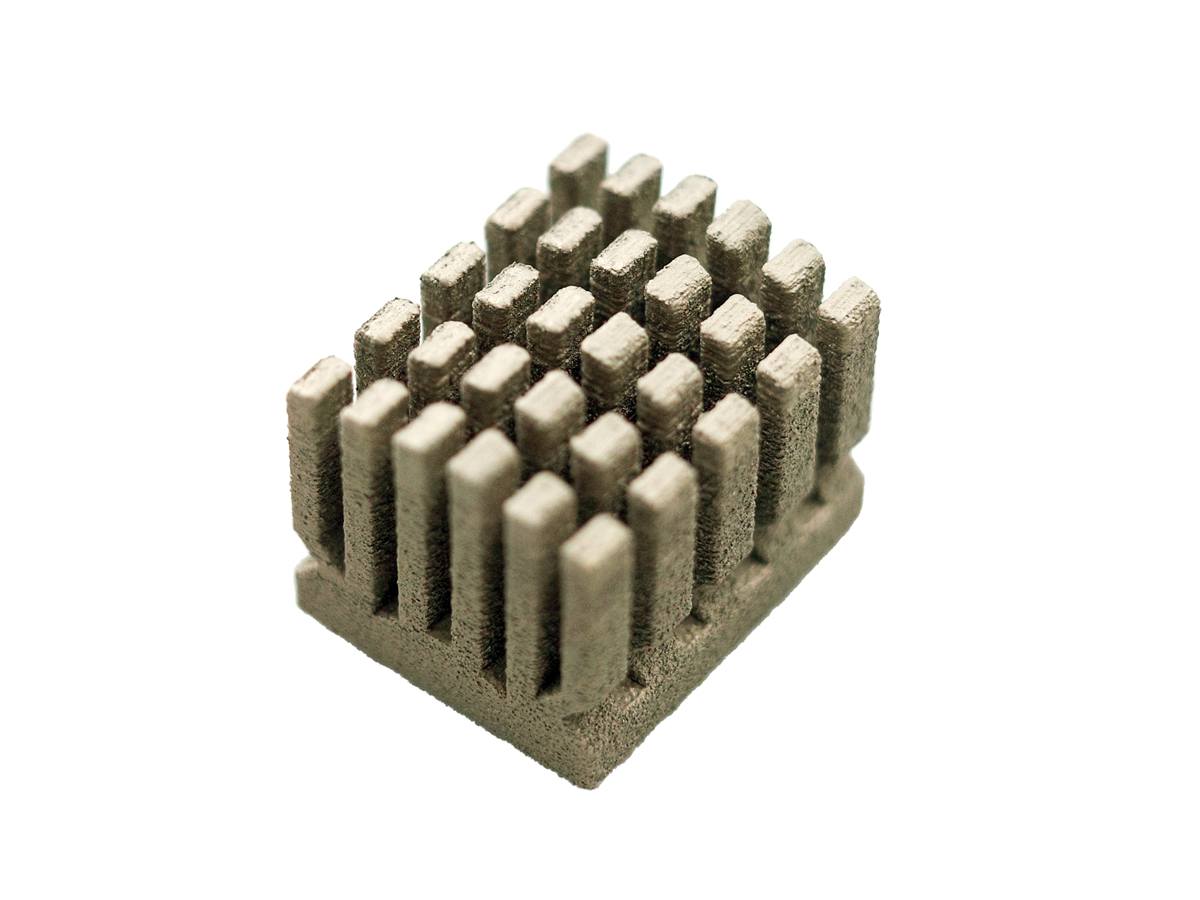

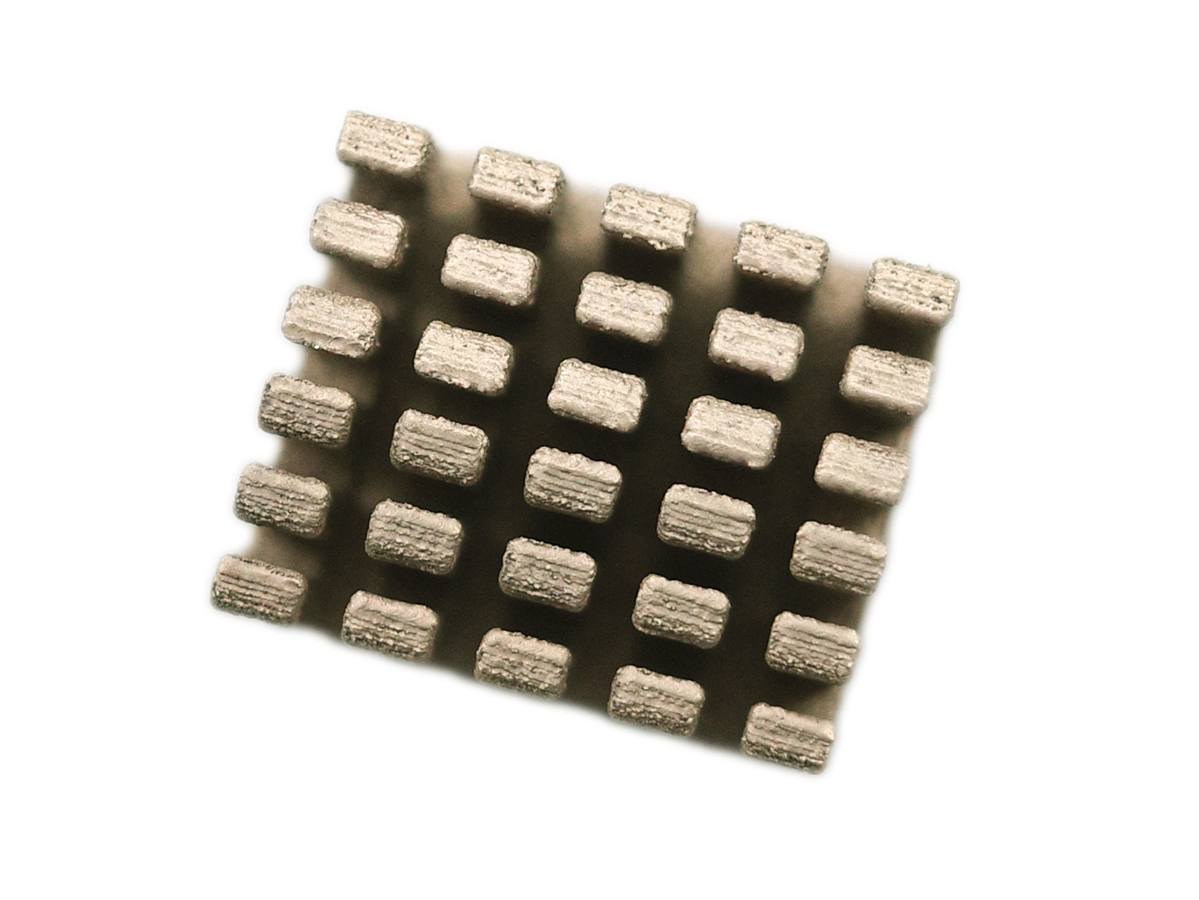

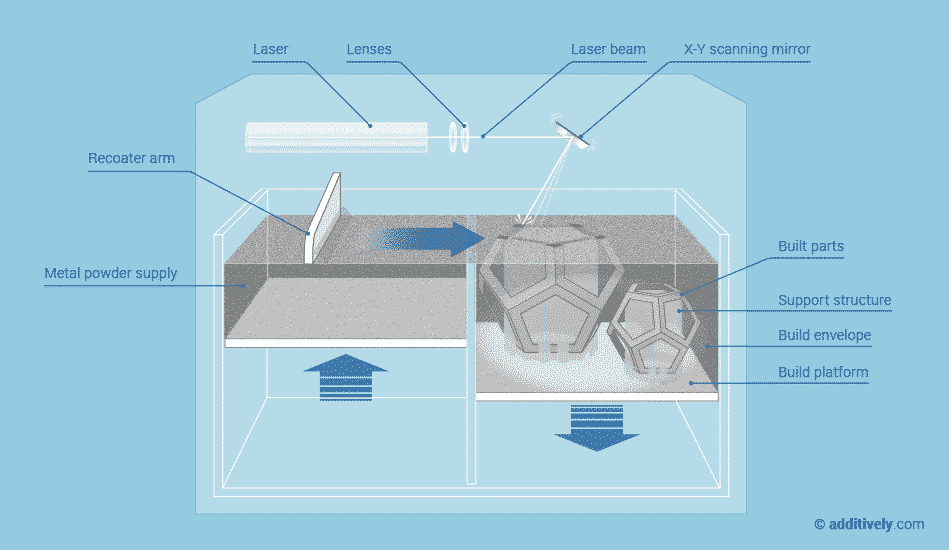

Selective Laser Melting creates objects from thin layers of powdered material by selectively melting it using a high power laser. The process takes place in a low oxygen environment in order to reduce thermal stresses and to prevent warping. Industrial metals are best used for high-tech, low-volume use cases from prototyping to creating end-use parts. Metal 3D prints are comparable to traditionally manufactured parts in terms of chemical composition, mechanical properties (static and fatigue) as well as microstructure. Once the printing is done, the extra powder that was not bound, and is not part of your design, is removed. Your part is now solid metal, and after the flutes are manually removed, it is tumbled and polished to produce a smooth finish.

|