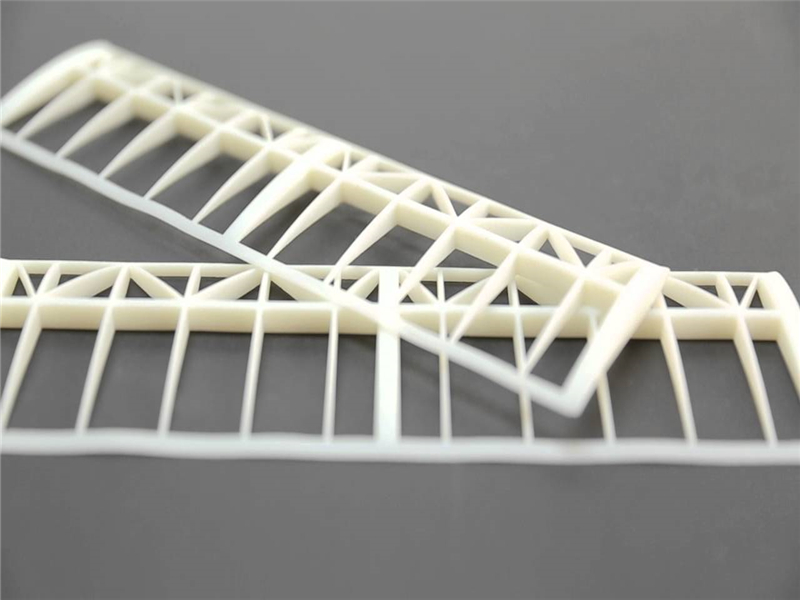

PolyJet PP-like ResinStratasys Rigur Rigurâs high-temperature resistance and strength make it ideal for form, fit and functional testing of parts that will be produced in polypropylene. Max Build Size Min Build Size 2 x 2 x 2 mm Default Layer Height 0.016 mm Optional Layer Heights 0.016 mm Tolerance Âą0.2% (with a lower limit of Âą0.2 mm) Up to 49 â Smooth â â â â â Detail â â â â â Accuracy â â â â â Rigidity â â â â Flexibility â â â â â Available ColorsWhite

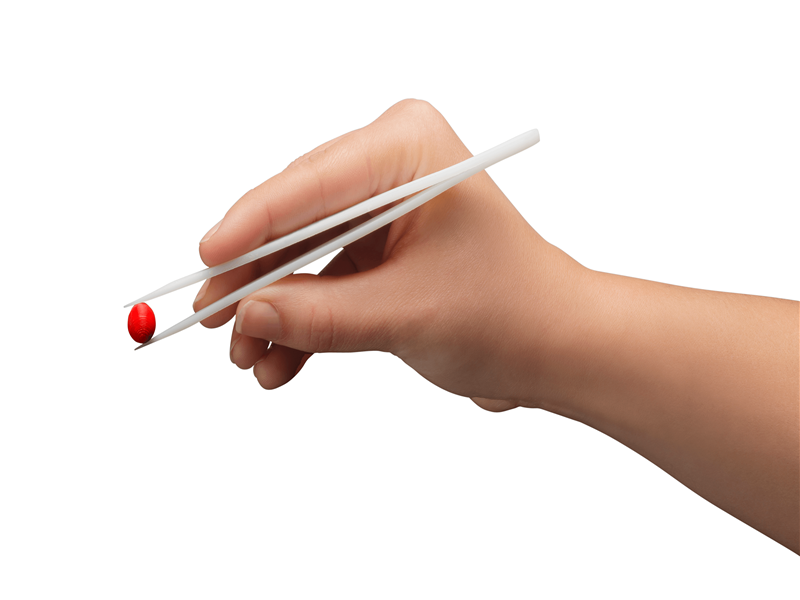

Available Post ProcessSuitable For Functional prototypes and end products, Not Suitable For Cavities within design (unless making use of escape holes), Additional InfoRigur, an advanced simulated polypropylene, offers durability and a smooth finish. 3D print precision prototypes that look and behave like polypropylene. Rapidly create models to test form, fit and function for snap-fit assemblies, living hinges and durable housings and packaging. Rigur delivers reliable performance and superior toughness, building parts with fine resolution and a smooth finish. 3D print with precision in bright white, or for added versatility, combine Rigur with Digital and flexible materials to produce a range of gray-scale shades and Shore A values. Quickly print tough prototypes for snap-fit components, living hinges and other demanding applications.

Feature

3D PrinterMaterial Spec Sheet

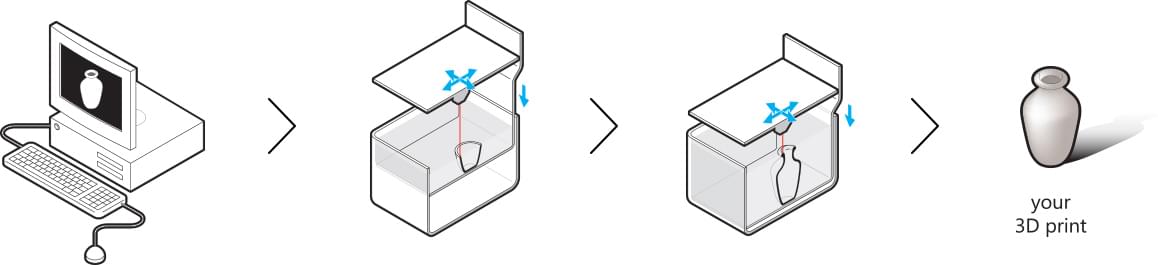

PolyJet prototyping technology is used to build your design with this material. Stratasys’ patented PolyJet inkjet technology works by jetting photopolymer materials in ultra-thin layers onto a build tray, layer by layer until the model is completed. Each photopolymer layer is cured by UV light immediately after being jetted, producing fully cured models that can be handled and used immediately. The gel-like support material, which is specially designed to support complicated geometries, can easily be removed by hand and water jetting.

|