MJP Frosted Detail Resin3D Systems Visijet M3 X This opaque white plastic delivers ABS-like performance and feel with high temperature resistance and toughness for rigorous applications. Max Build Size Min Build Size 2 x 2 x 2 mm Default Layer Height 0.016 mm Optional Layer Heights 0.016, 0.032 mm Tolerance ┬▒0.1% (with a lower limit of ┬▒0.1 mm) N/A Smooth ŌśģŌśģŌśģŌśģ Detail ŌśģŌśģŌśģŌśģŌśģ Accuracy ŌśģŌśģŌśģŌśģŌśģ Rigidity ŌśģŌśģŌśģŌśģ Flexibility ŌśģŌśģŌśģ Available ColorsTranslucent

, Painted

Available Post ProcessPaint

Suitable For Functional prototypes and end products, Not Suitable ForLarge models Additional InfoThis material utilizes a waxy support material that is dissolved after printing is completed. Because the support material slightly changes the texture of the product, and isnŌĆÖt applied to the entire product, you will see slight variability in texture over the surface of the model. The pricing model of Frosted Detail Plastics gives you transparency and a high level of control to manage the costs of the 3D print with design decisions. In general, minimum wall varies based on features The more stress is put on your object, the thicker it has to be. While the minimum wall is 0.3mm, this does not mean all parts of your structure will be strong enough at those thicknesses. For most designs, we recommend designing thicker walls as 0.3mm walls remain very, very brittle. Wires that support objects (like trees or lollipops), for instance, need to be thickened so they don’t snap. Parts that jut out are more likely to break during shipping To protect your pieces, sometimes it is helpful to build a cage around your object. This is especially true for thin wires that jut out (like the post on a model ship), the thinner the structure the more brittle the part. However, please note that a cage might cause some leftover support material on your part, meaning your part might be slightly yellow. If you plan on painting your model, we recommend cleaning off any excess wax before painting because the wax prevents paint from sticking. Alternatively, you can thicken the wires that jut out to 0.6 – 0.8mm thick.

Feature

3D PrinterMaterial Spec Sheet

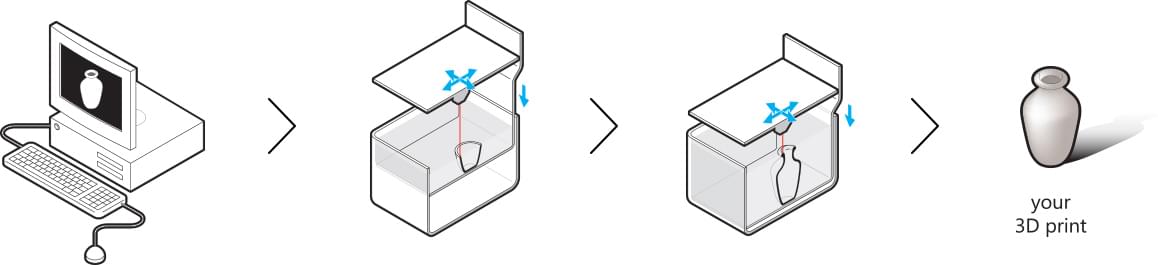

PolyJet prototyping technology is used to build your design with this material. Stratasys’ patented PolyJet inkjet technology works by jetting photopolymer materials in ultra-thin layers onto a build tray, layer by layer until the model is completed. Each photopolymer layer is cured by UV light immediately after being jetted, producing fully cured models that can be handled and used immediately. The gel-like support material, which is specially designed to support complicated geometries, can easily be removed by hand and water jetting.

|