MJF Nylon PA11HP 3D High Reusability PA11 This thermoplastic delivers optimal mechanical properties, ideal for strong, ductile, functional parts. It also has excellent chemical resistance and enhanced elongation-at-break. Ideal for impact resistance and ductility for prostheses, insoles, sports goods, snap fits, living hinges, and more. Max Build Size Min Build Size 5 x 5 x 5 mm Default Layer Height 0.08 mm Optional Layer Heights 0.08 mm Tolerance ┬▒0.2% (with a lower limit of ┬▒0.2 mm) Up to 110 Ōäā Smooth ŌśģŌśģŌśģŌśģ Detail ŌśģŌśģŌśģŌśģ Accuracy ŌśģŌśģŌśģŌśģ Rigidity ŌśģŌśģŌśģ Flexibility ŌśģŌśģŌśģŌśģŌśģ Available ColorsGrey

Available Post ProcessPaint

Suitable For Functional prototypes and end products, Not Suitable ForCavities within design (unless making use of escape holes) Additional InfoProduce strong, ductile, functional parts ŌĆó Thermoplastic material delivering optimal mechanical properties. ŌĆó Renewable raw material from vegetable castor oil (reduced environmental impact) ŌĆó Provides excellent chemical resistance4 and enhanced elongation-at-break ŌĆó Impact resistance and ductility for prostheses, insoles, sports goods, snap fits, living hinges, and more.

Feature

3D PrinterMaterial Spec Sheet

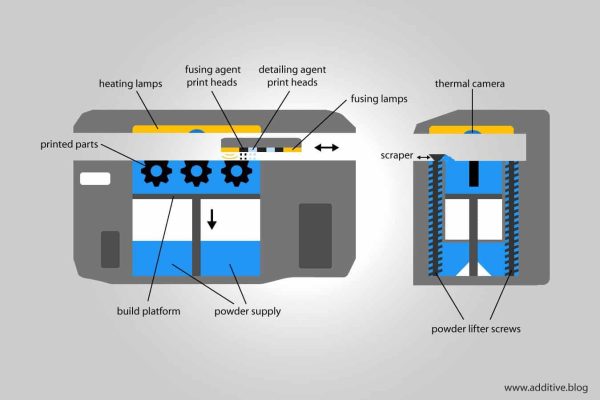

In this process a fusing agent is applied on a material layer where the particles are destined to fuse together. Then a detailing agent is applied to modify fusing and create fine detail and smooth surfaces. To finish, the area is exposed to energy that will lead reactions between the agents and the material to create the part. When the printing process is complete, the build box is removed from the printer. An operator carefully extracts the parts from the build box and removes the remaining powder thanks to brushes and air blowers.

|