FDM Stratasys Nylon 12Stratasys FDM Nylon 12 Nylon 12(FDM) is tough, has good impact resistance and high fatigue resistance, making it suitable for snap fit closures. Max Build Size Min Build Size 5 x 5 x 5 mm Default Layer Height 0.15 mm Optional Layer Heights 0.15 mm Tolerance ┬▒0.2% (with a lower limit of ┬▒0.2 mm) Up to 97 Ōäā Smooth ŌśģŌśģŌśģ Detail ŌśģŌśģŌśģŌśģ Accuracy ŌśģŌśģŌśģŌśģ Rigidity ŌśģŌśģŌśģŌśģŌśģ Flexibility ŌśģŌśģŌśģŌśģŌśģ Available ColorsBlack

Available Post ProcessSuitable For Functional prototypes and end products, Not Suitable For Cavities within design (unless making use of escape holes), Additional InfoFDM Nylon 12 combines strength with excellent fatigue properties suitable for repetitive closures, snap fits and vibration-resistant parts. Get the performance of an engineering plastic with the dependability of FDM technology. FDM Nylon 12 has good strength properties, resistance to moderate chemicals and high fatigue resistance. These characteristics make it a good choice for applications involving snap-fit closures, tools with press-fit inserts, components subject to high vibration and parts requiring threaded inserts.

Feature

3D PrinterMaterial Spec Sheet

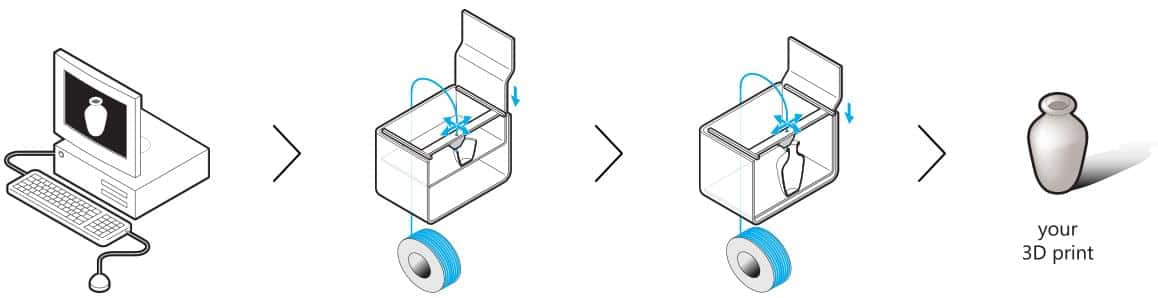

Fused Deposition Modeling is used to build your design with this material. The principle is simple. You can compare it with a hot glue gun into which you put sticks of glue. The glue is heated up until it melts and is then pushed through a fine nozzle in the front of the glue gun. In an FDM printer, a long plastic wire is used in place of glue. It is fed from a spool to the nozzle where the material is liquefied and ŌĆśdrawnŌĆÖ on the platform where it immediately hardens again. The nozzle moves to drop the material at the correct location, drawing your model line by line. When a layer is drawn, the platform lowers by one layer thickness so the printer can start with the next layer. When your model contains overhanging sections, the printer needs to build supporting material. Since the material of the model cannot be deposited in the air, the support material prevents it from falling down. This support material is fed through another nozzle. Afterward, when the model is put into a bath with special soap, the support material dissolves.

|