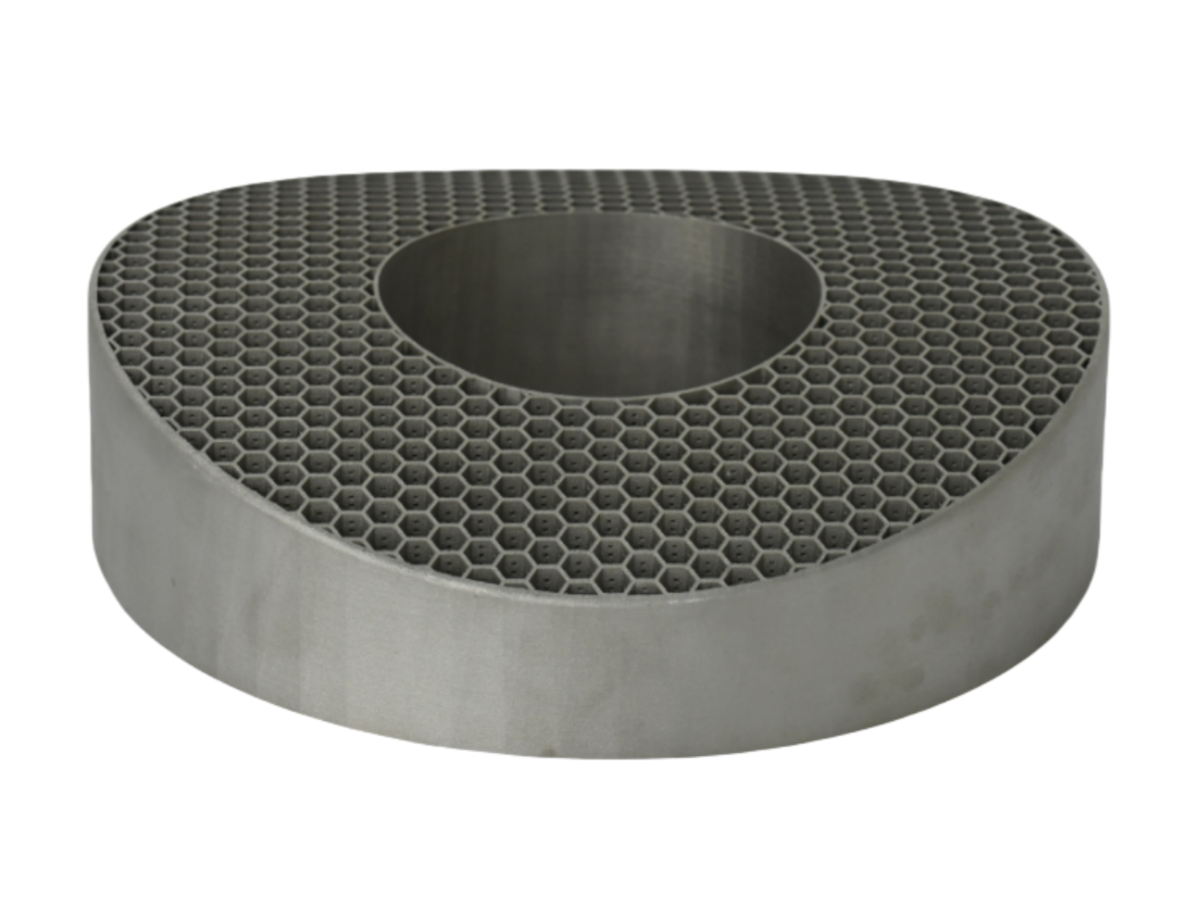

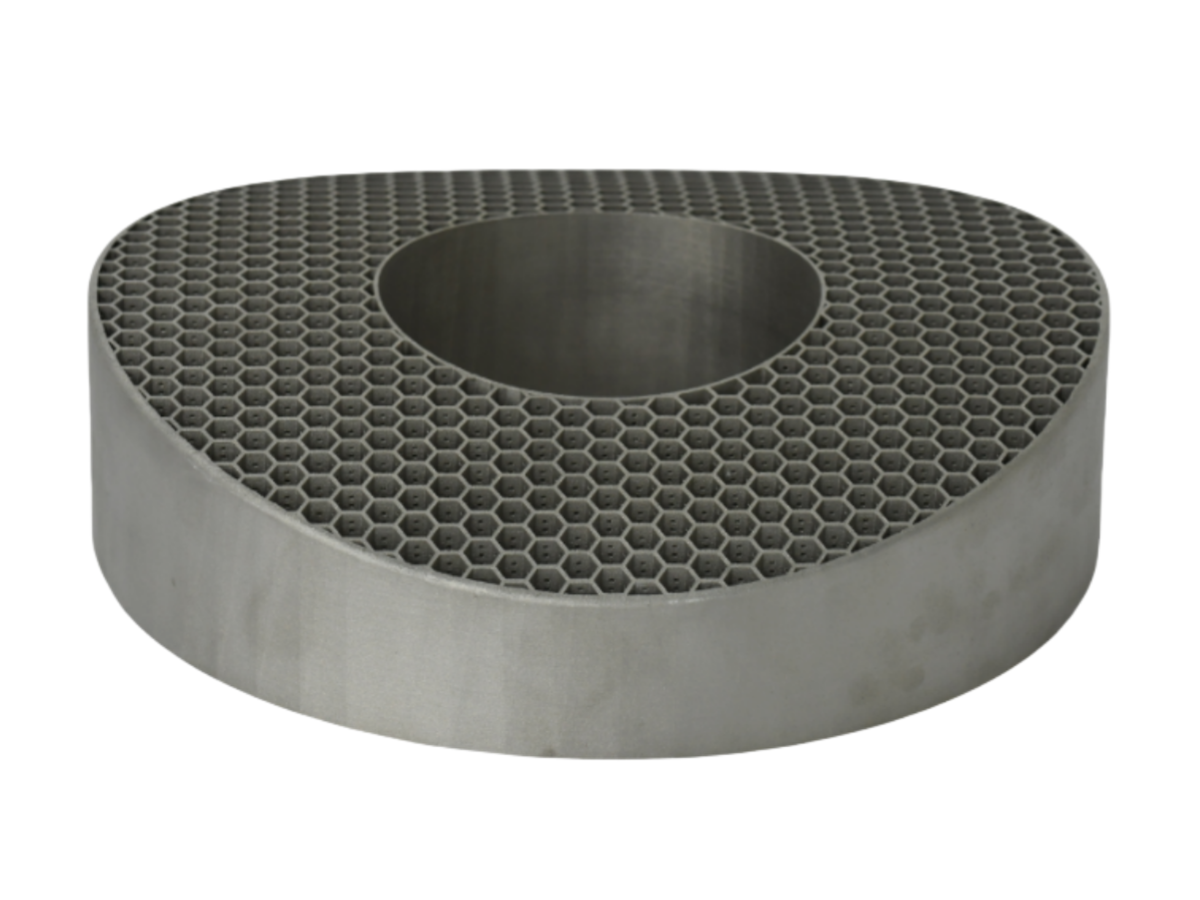

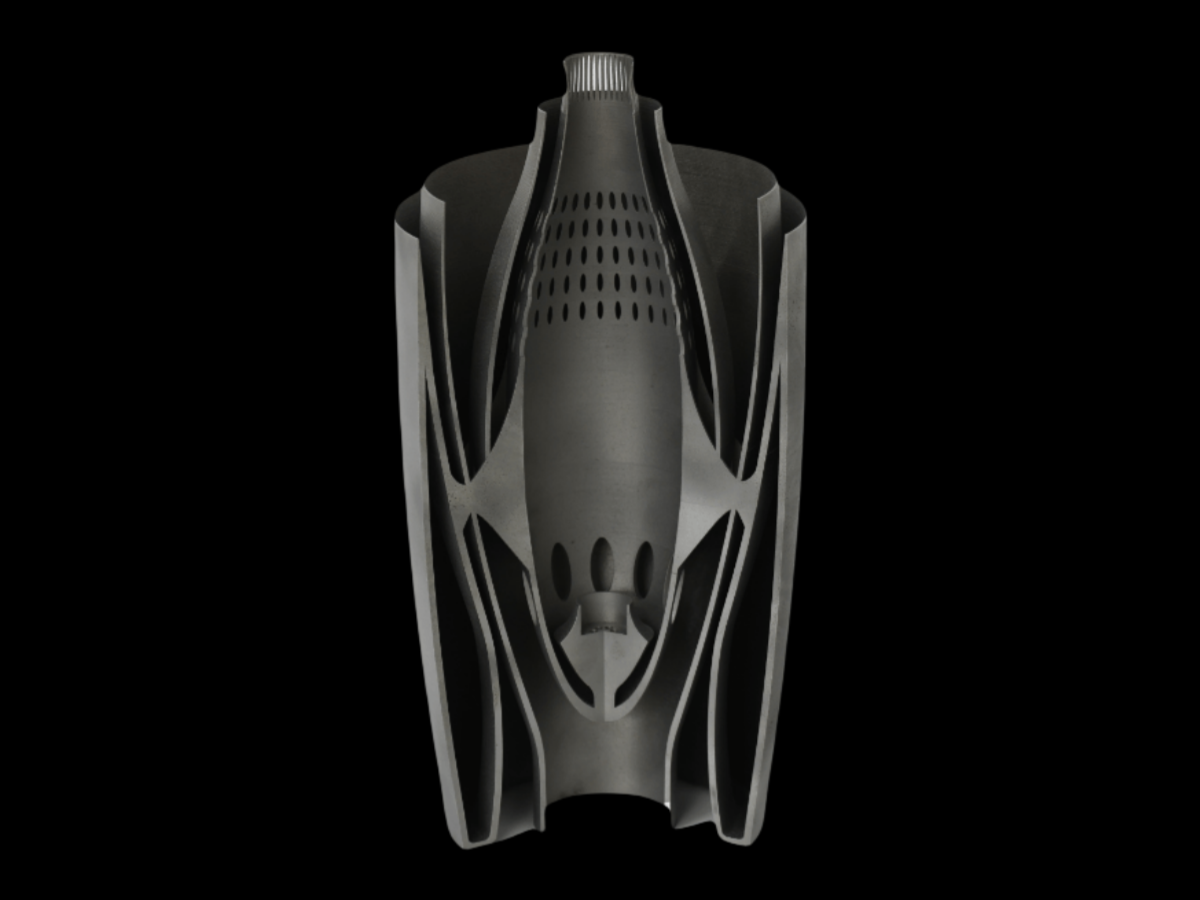

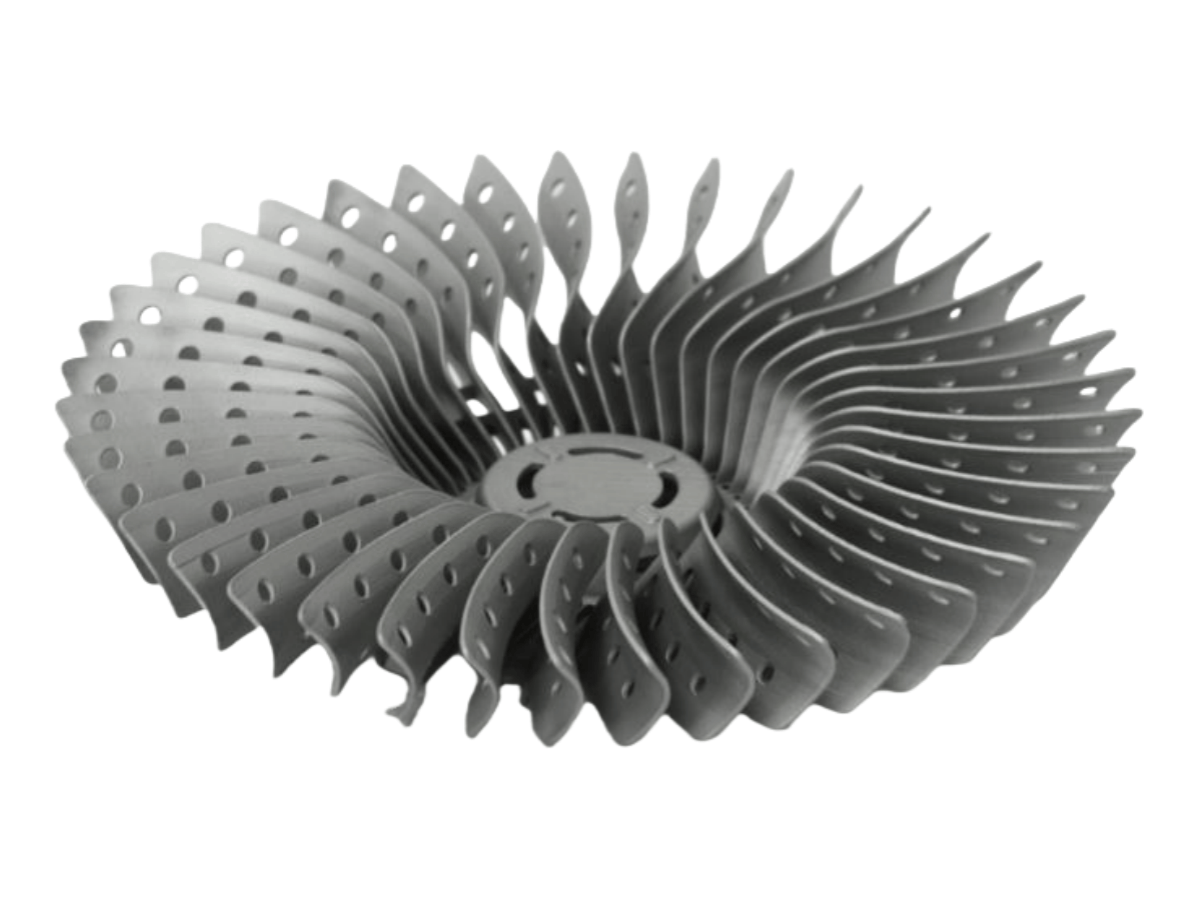

SLM Inconel 625IN625/GH6625 IN625 is a high-performance nickel-based superalloy renowned for its exceptional strength, corrosion resistance, and ability to withstand extreme temperatures. It excels in harsh environments, making it ideal for demanding applications in aerospace, chemical processing, and marine industries. Max Build Size Min Build Size 5 x 5 x 5 mm Default Layer Height 0.05 mm Optional Layer Heights 0.05 mm Tolerance Âą0.2% (with a lower limit of Âą0.2 mm) Up to 980 â Smooth â â â Detail â â â Accuracy â â â â Rigidity â â â â â Flexibility â â Available ColorsMetal

Available Post ProcessPaint

, Polish

, Sandblast

Suitable For Functional prototypes and end products, Not Suitable For Complex designs with intricate details, Additional Info

Feature

3D PrinterMaterial Spec Sheet

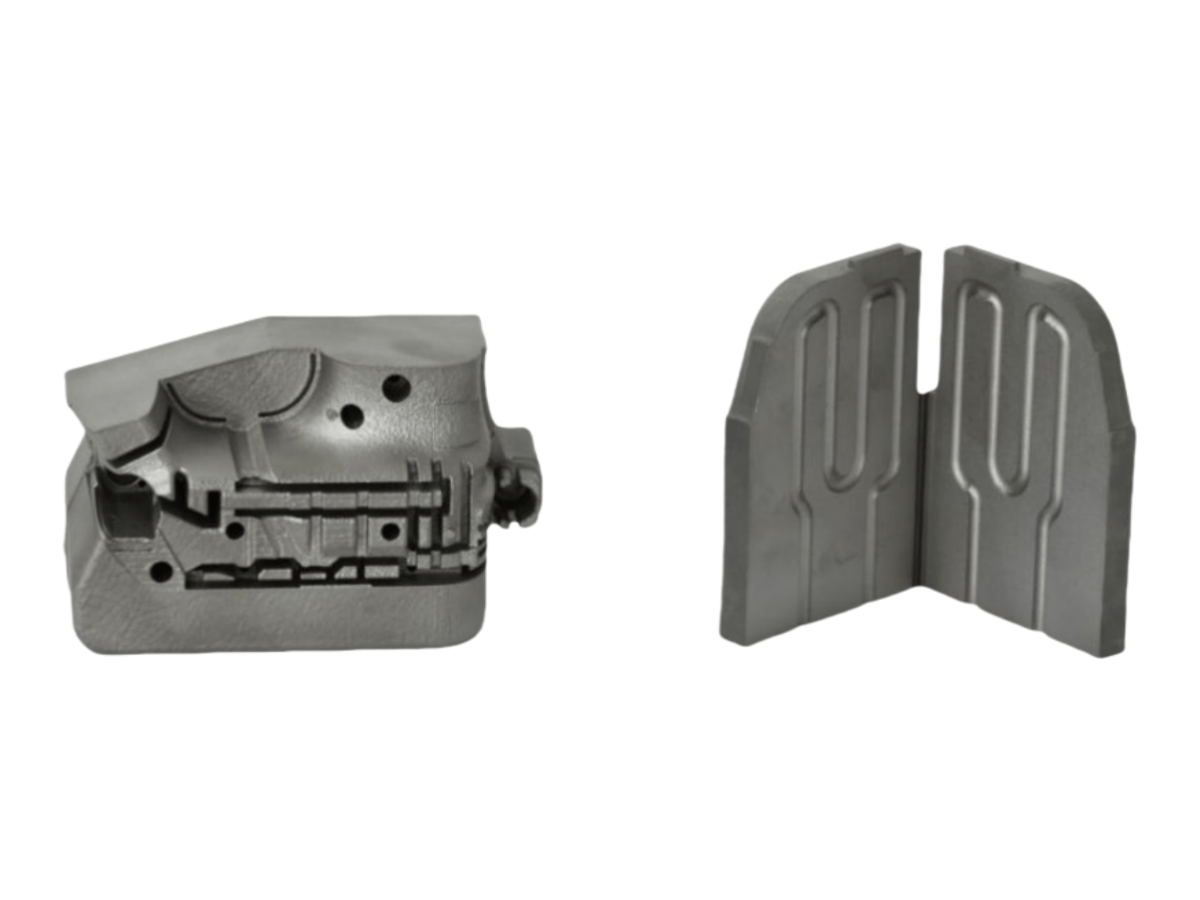

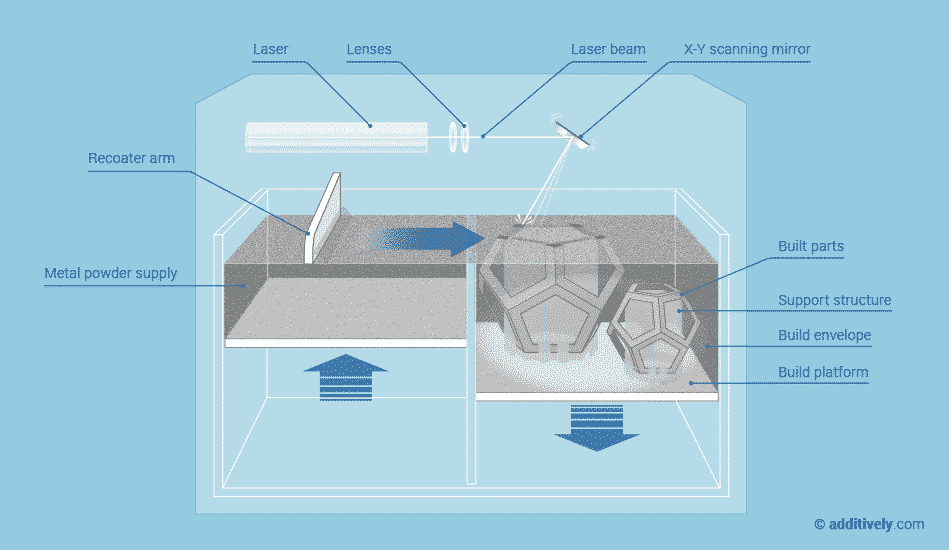

Selective Laser Melting creates objects from thin layers of powdered material by selectively melting it using a high power laser. The process takes place in a low oxygen environment in order to reduce thermal stresses and to prevent warping. Industrial metals are best used for high-tech, low-volume use cases from prototyping to creating end-use parts. Metal 3D prints are comparable to traditionally manufactured parts in terms of chemical composition, mechanical properties (static and fatigue) as well as microstructure. Once the printing is done, the extra powder that was not bound, and is not part of your design, is removed. Your part is now solid metal, and after the flutes are manually removed, it is tumbled and polished to produce a smooth finish.

|