DMLS Cobalt ChromeCoCrMoW ┬Ę SP2 Max Build Size Min Build Size 5 x 5 x 5 mm Default Layer Height 0.035 mm Optional Layer Heights 0.05 mm Tolerance ┬▒0.2% (with a lower limit of ┬▒0.2 mm) N/A Smooth ŌśģŌśģŌśģ Detail ŌśģŌśģŌśģŌśģ Accuracy ŌśģŌśģŌśģŌśģ Rigidity ŌśģŌśģŌśģŌśģŌśģ Flexibility ŌśģŌśģŌśģ Available ColorsMetal

Available Post ProcessPolish

, Sandblast

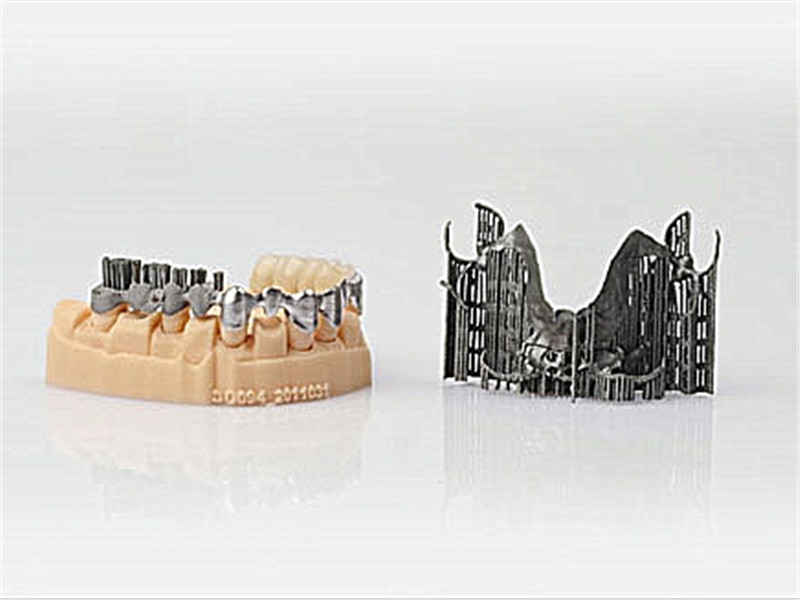

Suitable For Functional prototypes and end products, Not Suitable For Complex designs with intricate details, Additional InfoParts built from EOS CobaltChrome MP1 conform to the chemical composition UNS R31538 of high carbon CoCrMo alloy. They are nickel-free (< 0.1 % nickel content) and are characterized by a fine, uniform crystal grain structure. As built EOS CobaltChrome MP1 meets the chemical and mechanical specifications of ISO 5832-4 and ASTM F75 for cast CoCrMo implant alloys, as well as the specifications of ISO 5832-12 and ASTM F1537 for wrought CoCrMo implants alloys except remaining elongation. The remaining elongation can be increased to fulfil even these standards by high temperature stress relieving or hot isostatic pressing (HIP).

Feature

3D PrinterMaterial Spec Sheet

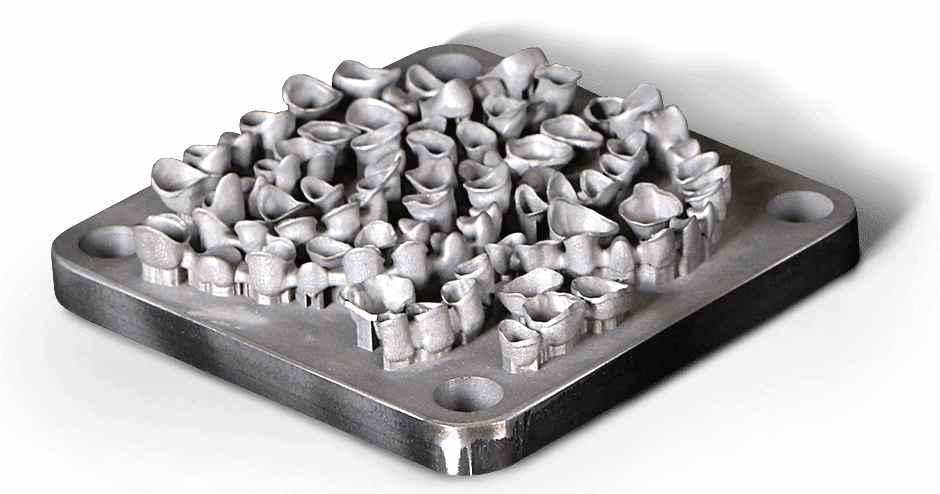

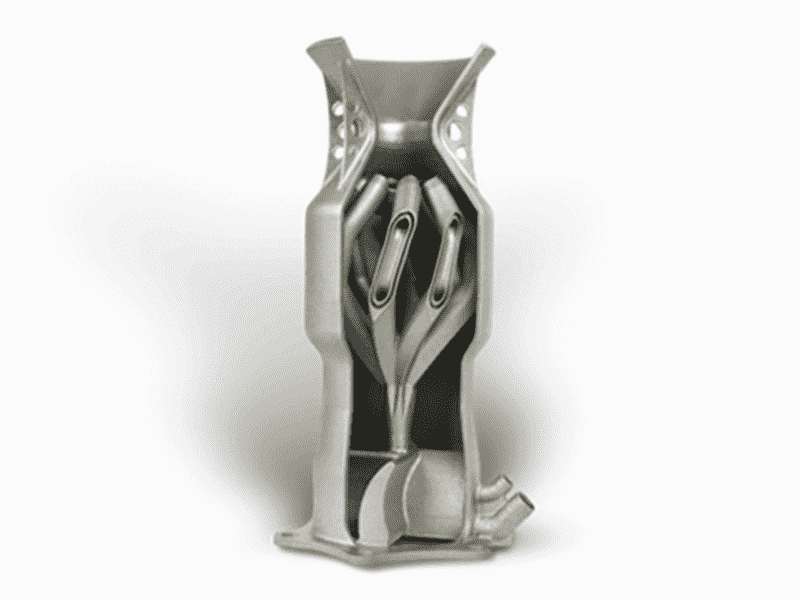

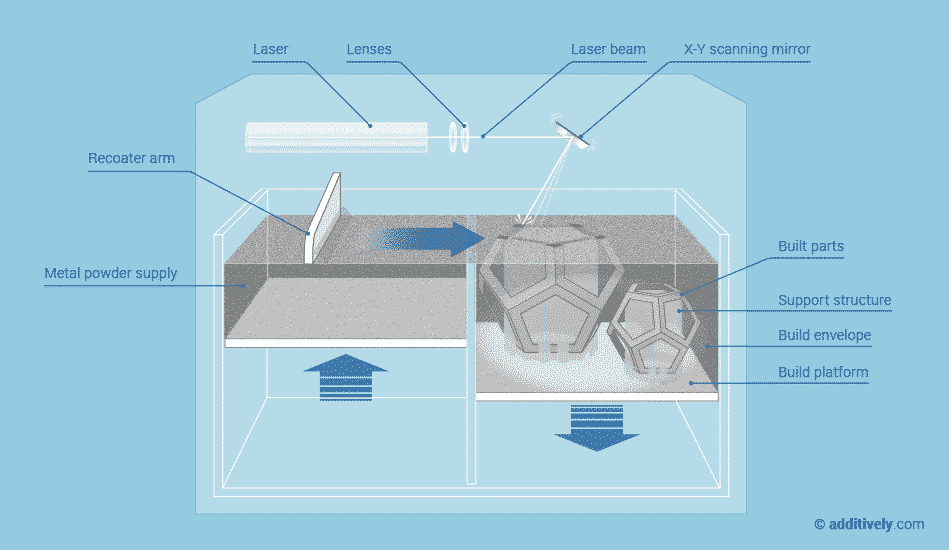

Selective Laser Melting creates objects from thin layers of powdered material by selectively melting it using a high power laser. The process takes place in a low oxygen environment in order to reduce thermal stresses and to prevent warping. Industrial metals are best used for high-tech, low-volume use cases from prototyping to creating end-use parts. Metal 3D prints are comparable to traditionally manufactured parts in terms of chemical composition, mechanical properties (static and fatigue) as well as microstructure. Once the printing is done, the extra powder that was not bound, and is not part of your design, is removed. Your part is now solid metal, and after the flutes are manually removed, it is tumbled and polished to produce a smooth finish.

|