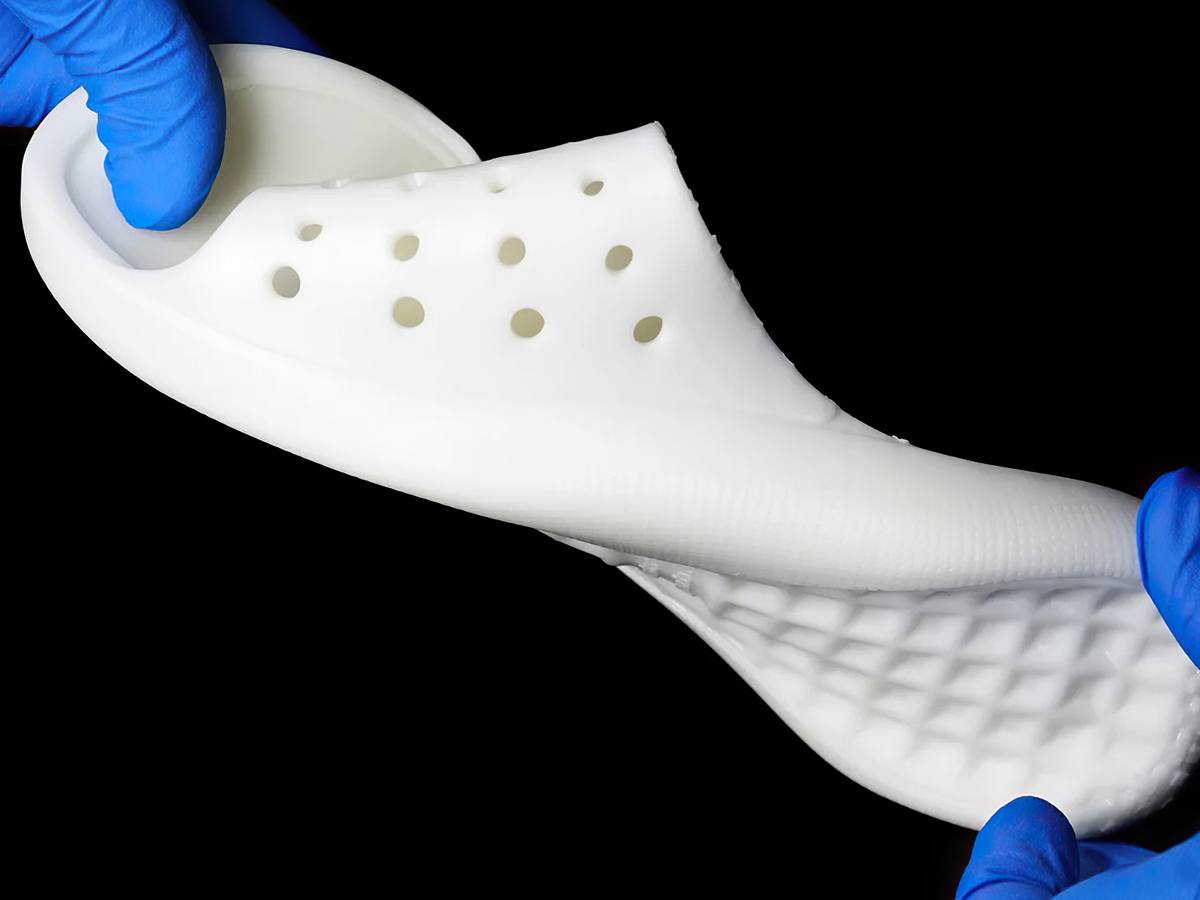

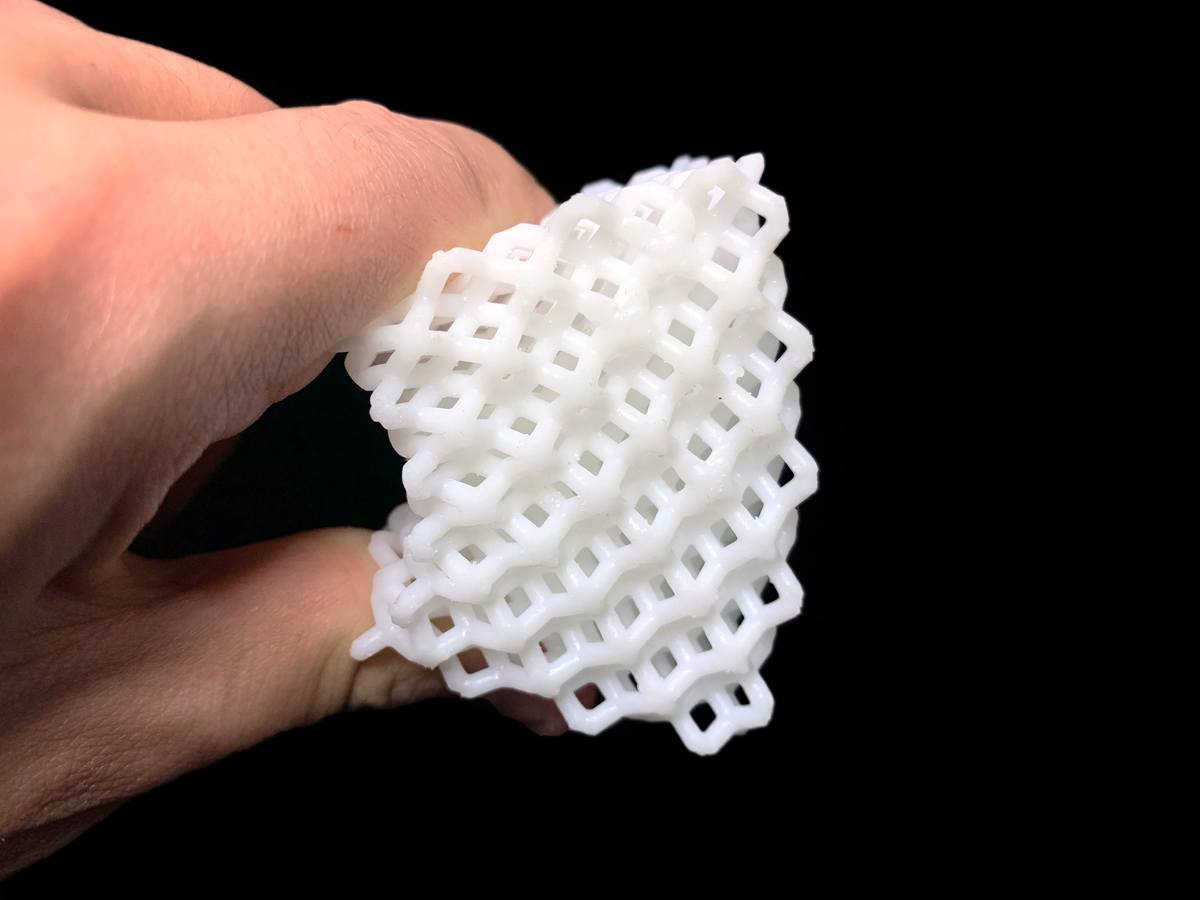

LCD Rubber-like ResinRESIONE F39 This 75A ShoreA durometer material is suitable for prototyping parts normally produced with silicone like shoe sole and connectors. DLP resin is ideal for parts that will bend, stretch, compress, and hold up to repeated cycles without tearing. Max Build Size Min Build Size 5 x 5 x 5 mm Default Layer Height 0.1 mm Optional Layer Heights 0.05, 0.1 mm Tolerance ┬▒0.2% (with a lower limit of ┬▒0.2 mm) Up to 50 Ōäā Smooth ŌśģŌśģŌśģŌśģ Detail ŌśģŌśģŌśģ Accuracy ŌśģŌśģŌśģ Rigidity Ōśģ Flexibility ŌśģŌśģŌśģŌśģŌśģ Available ColorsWhite

Available Post ProcessSuitable For Cases, holders, adapters, Not Suitable For Complex designs with intricate details, Additional InfoLCD Flexible Resin is ideal for:

Feature

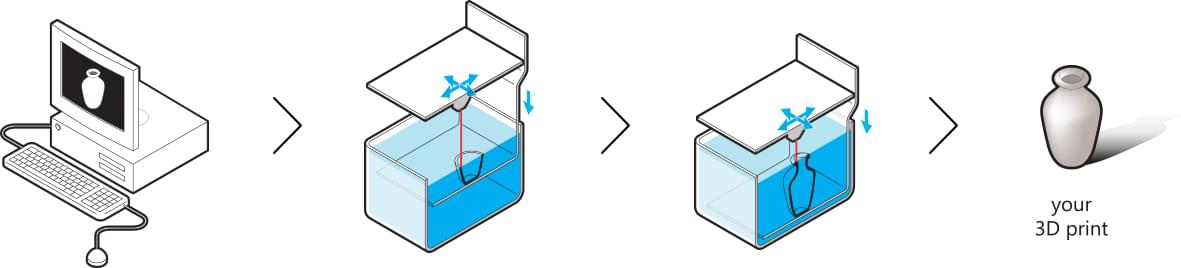

3D PrinterCustomized LCD Printer Material Spec Sheet

Stereolithography is used to build your design with this material.Starting from a 3D model, a model is built by cutting it into thin layers via specialized software. A support structure is created, where needed, in order to deal with overhangs and cavities. The process takes place in a large tank and begins when a layer of liquid polymer is spread over a platform. This machine then uses a computer controlled laser to draw the first layer onto the surface of a liquid polymer, which hardens where struck by the laser. The model is then lowered and the next layer is then drawn directly on top of the previous one. This is repeated until the model is finished. In this way, layer by layer, an object is ŌĆ£drawnŌĆØ in the liquid by the beam, with the layers being consolidated throughout the process. When the object is complete, it is raised out of the tank via the supporting platform ŌĆō much like a submarine rising to the surface of the water ŌĆō with the excess liquid flowing away. The supports are removed manually after the model is taken from the machine.

|