Gallery

About Project

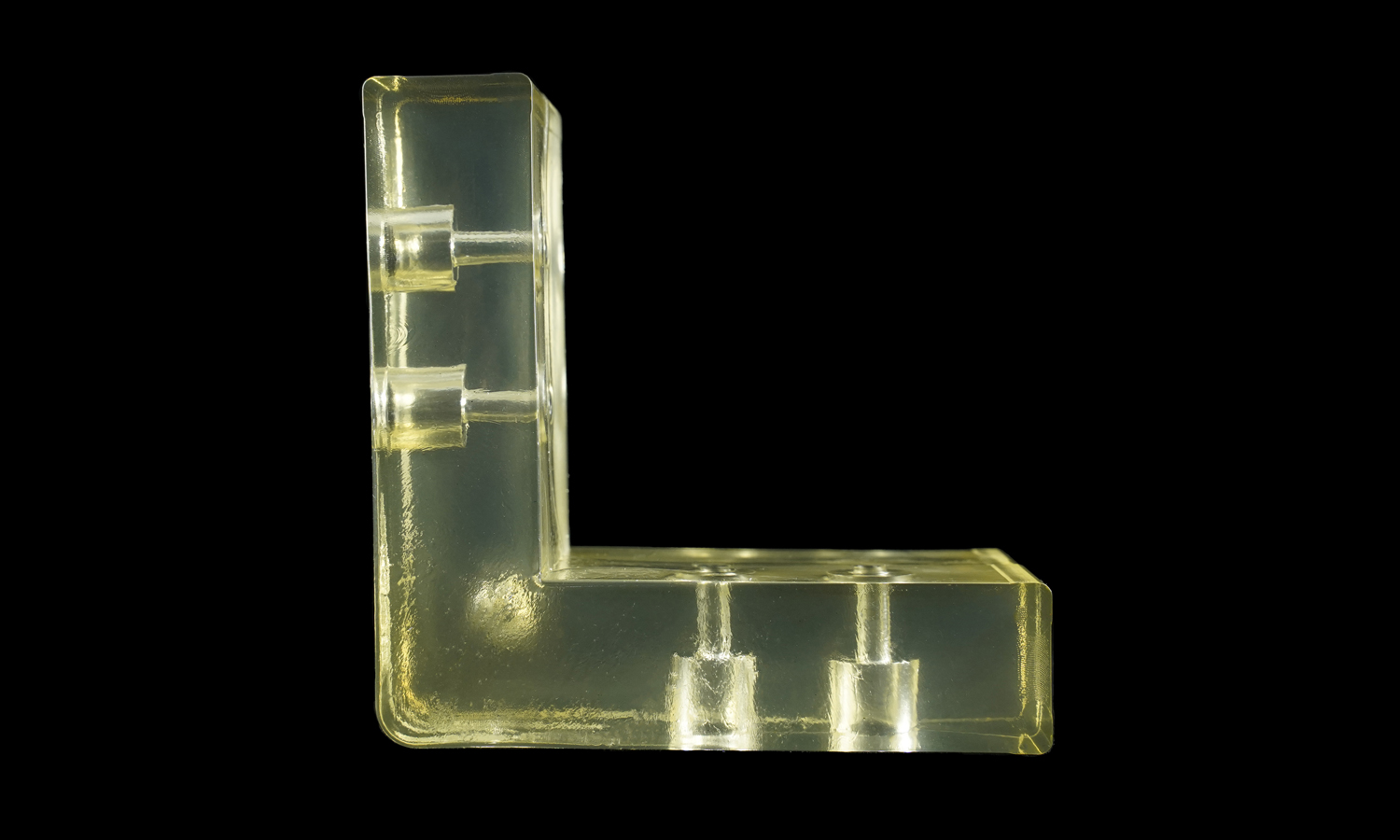

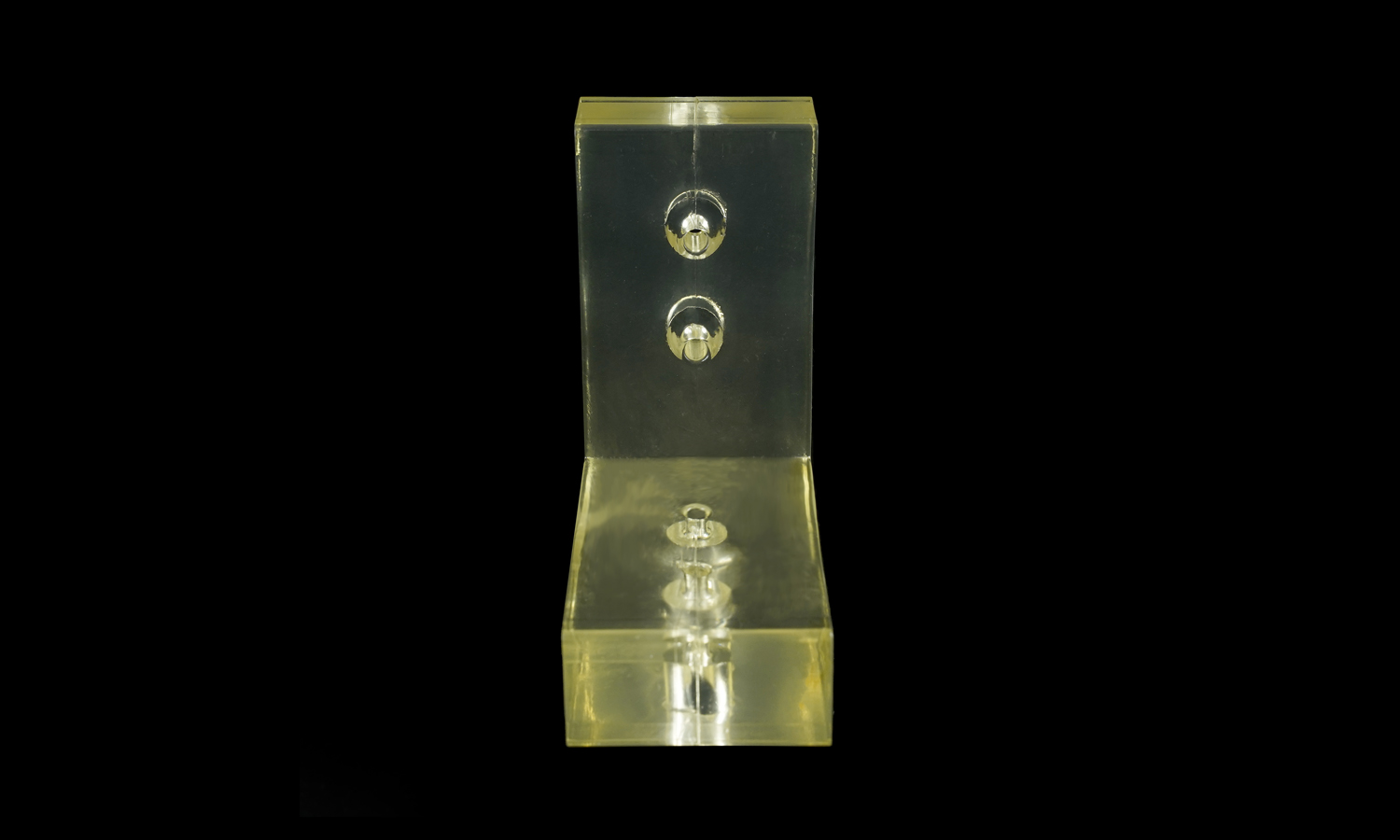

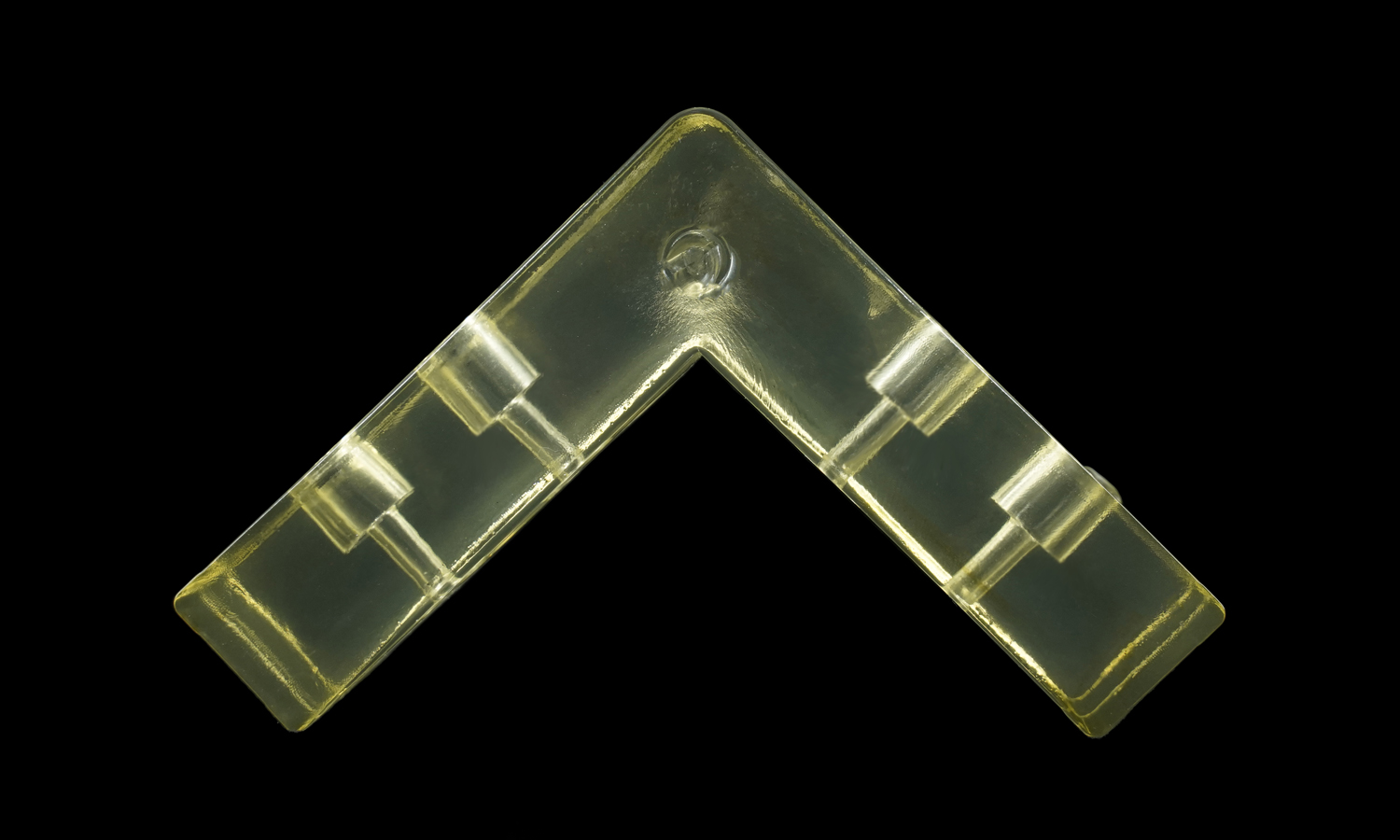

This L-shaped transparent component demonstrates the precision and clarity achievable through vacuum casting. The part features a compact right-angle structure with smooth outer surfaces, embedded cylindrical holes, and clean internal channels that remain visible through the resin body. Its appearance is similar to acrylic but slightly warmer in tone, suggesting a high-grade clear polyurethane or epoxy resin.

The design includes multiple threaded or insert-ready holes positioned along both vertical and horizontal planes, allowing it to serve as a fixture, bracket, or optical alignment component. Such transparent brackets are often used in engineering validation, optical instrument prototypes, or mechanical assemblies that require precise internal observation- for example, verifying how light or fluid passes through the structure or testing the fit of embedded parts.

The overall clarity and absence of trapped bubbles indicate professional vacuum casting and post-processing. This method offers near-injection-molding surface quality at a fraction of the tooling cost, ideal for low-volume production and functional testing.

Why Choose FacFox

FacFox’s urethane casting service provides exceptional results for transparent or tinted resin parts, matching the optical smoothness of injection molding while preserving flexibility for design iteration. Whether you’re developing optical housings, brackets, or functional enclosures, our team ensures precision, durability, and visual excellence through controlled casting and finishing processes.

Solution

- Step 1: A master model was fabricated, likely CNC-machined or high-resolution 3D printed, to create the reference shape.

- Step 2: The master was encapsulated in liquid silicone and cured to form a flexible mold.

- Step 3: After removing the master, a clear two-part polyurethane resin was mixed and vacuum-degassed.

- Step 4: The resin was poured into the mold under vacuum or pressure to eliminate bubbles.

- Step 5: The mold was cured in a temperature-controlled chamber until the resin solidified.

- Step 6: The part was demolded, trimmed, and optionally polished or clear-coated for enhanced transparency.