- CNC Milled SS304 Fitting for Plumbing System

- SLA 3D Printed High-temp Resin 238Ōäā Fluid System Part

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

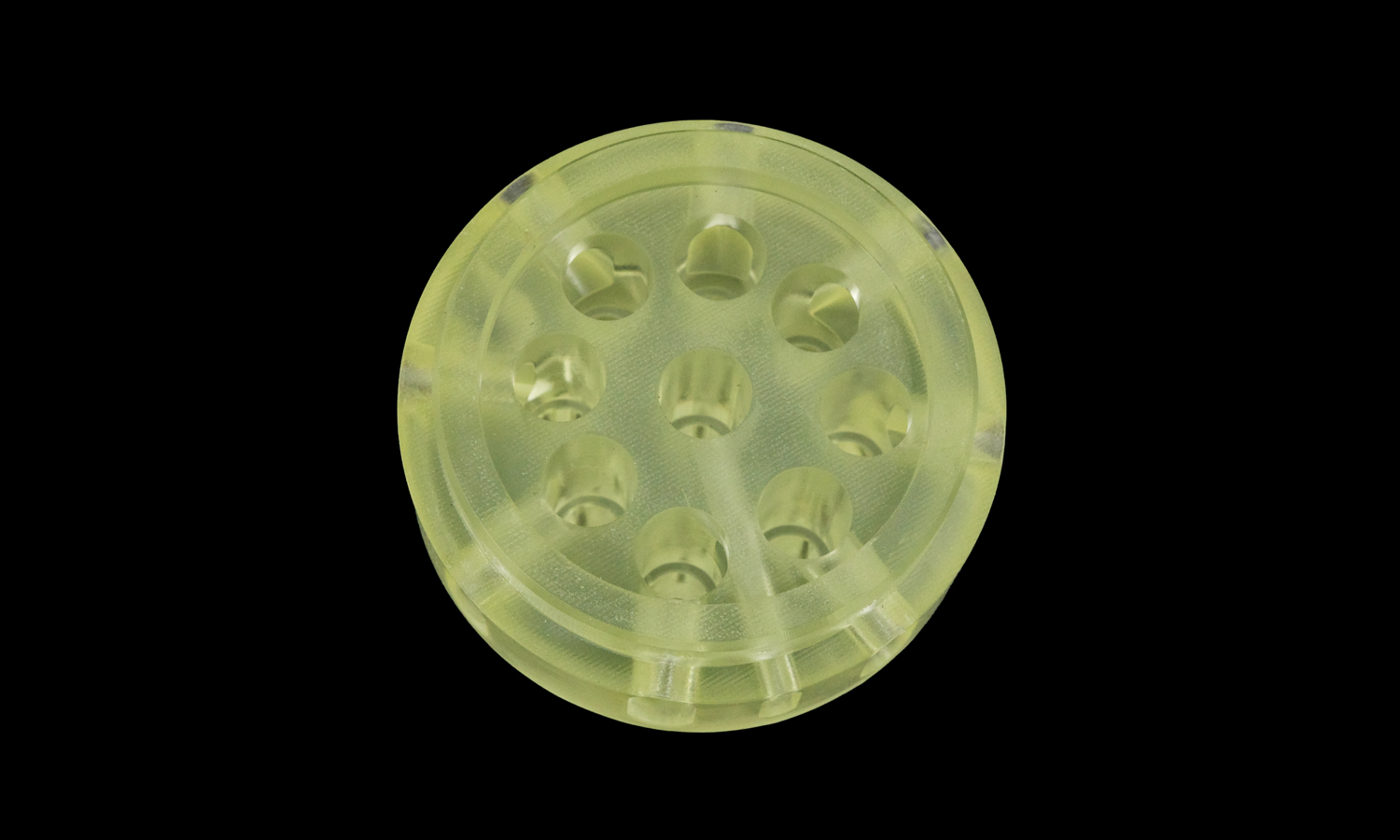

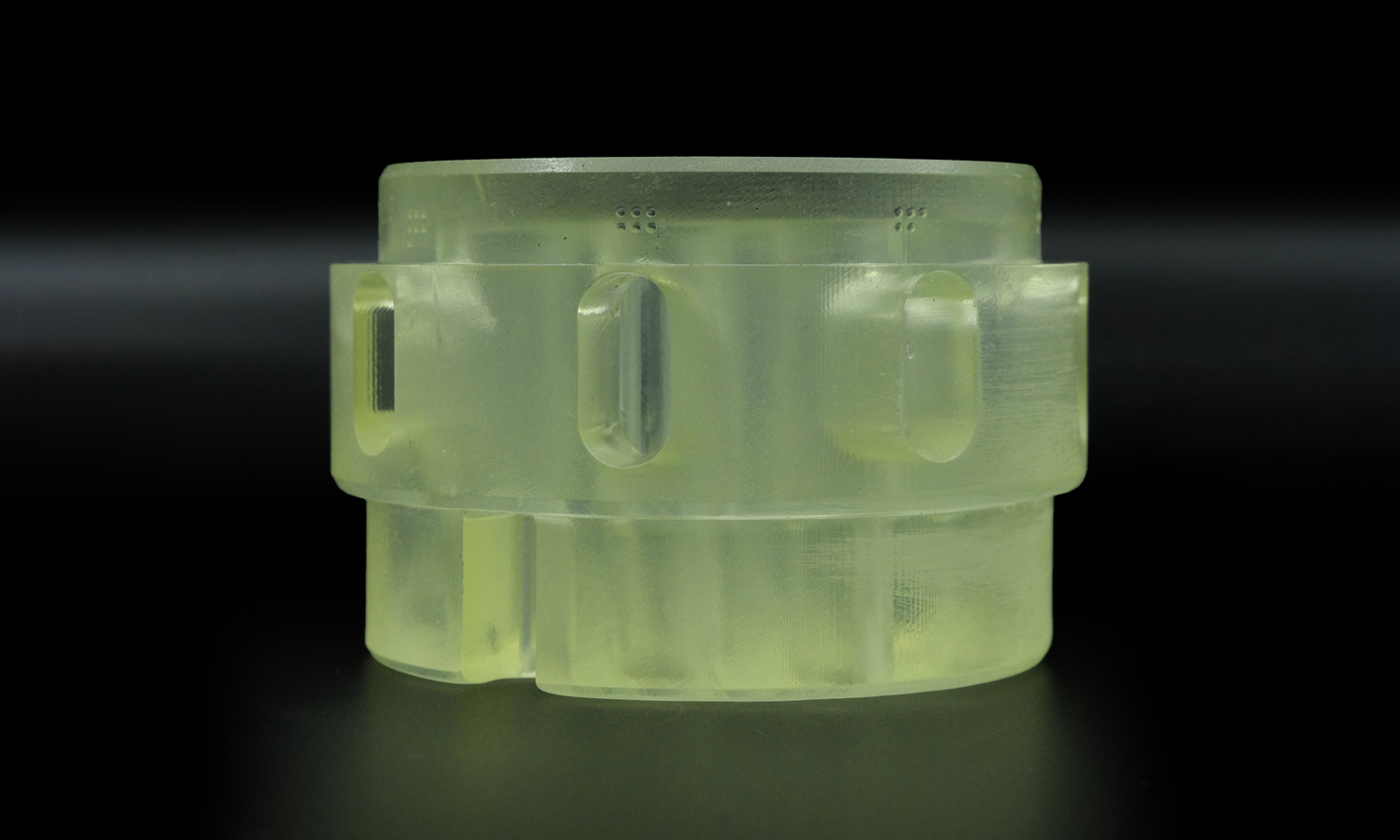

This image showcases a fascinating example of what’s possible with Stereolithography (SLA) 3D printing, specifically using Formlabs High Temp Resin. The object is a short, cylindrical manifold with a unique design.

Key Features

- Material: Formlabs High Temp Resin, known for its ability to withstand high temperatures. This particular resin boasts a Heat Deflection Temperature (HDT) of 238 Ōäā at 0.45 MPa, making it suitable for applications where thermal resistance is crucial.

- Design: The manifold features a central cylindrical structure surrounded by a ring. This ring incorporates cutouts that connect to nine evenly spaced holes on the top surface. This design suggests a potential application in fluid or gas distribution where precise and even flow is required.

- Aesthetics: The translucent yellow-green tint of the resin adds an interesting visual element to the part, highlighting the smooth surface finish achievable with SLA printing.

Why High Temp Resin?

The choice of Formlabs High Temp Resin opens up possibilities for using this manifold in environments where standard 3D printed materials might fail. Applications could include:

- Prototyping for high-temperature environments: Testing designs for parts that will eventually be manufactured in materials like metal or high-performance plastics.

- Custom tooling and fixtures: Creating jigs, molds, or fixtures that need to withstand elevated temperatures during manufacturing processes.

- Specialized components: Producing small-batch or custom parts for research, development, or niche industrial applications where heat resistance is a key requirement.

The level of detail and the smooth surface finish visible in the image are hallmarks of SLA 3D printing, a technology known for its precision and ability to create complex geometries.

Looking for High-Quality 3D Printing Services?

If you have a project that requires high accuracy and materials with specific properties like high temperature resistance, consider FacFox for your 3D printing needs. FacFox offers a wide range of materials and printing technologies, including SLA with engineering-grade resins like Formlabs High Temp. Their expertise and capabilities can help you bring your designs to life with exceptional quality and precision.

Solution

- Step 1: A digital 3D model of the manifold was designed using CAD software.

- Step 2: The 3D model was then sliced into thin cross-sectional layers by the 3D printer’s software.

- Step 3: The Formlabs High Temp Resin was poured into the resin tank of the SLA 3D printer.

- Step 4: A laser was directed by mirrors to selectively cure each layer of the resin, corresponding to the sliced design.

- Step 5: The build platform was lowered incrementally as each layer was solidified.

- Step 6: Once the printing process was complete, the build platform was raised, and the printed manifold was removed from the printer.

- Step 7: Excess uncured resin was washed off the manifold using a solvent, typically isopropyl alcohol (IPA).

- Step 8: The manifold was then post-cured under UV light to achieve its final mechanical properties and full strength, including its high temperature resistance.

- Step 9: Support structures, if used during printing, were carefully removed from the manifold.

- Step 10: The surface of the manifold was optionally finished to achieve the desired smoothness and appearance.