- Binder Jet 3D Printed SS316L Schwarz Diamond Surface with Raw Finishing

- SLM 3D Printed SS316L Impeller Component Mini Prototype for Nuclear Cooling System

Material Resin, Metal

Quantity 2 pcs

Price Range $100-1,000

Lead Time 5 workdays

Gallery

About Project

Injection molding is a common and efficient way to produce complex and high-quality parts. However, it also requires careful control of the temperature and heat transfer in the mold cavity, which can affect the part quality, cycle time, and energy consumption.

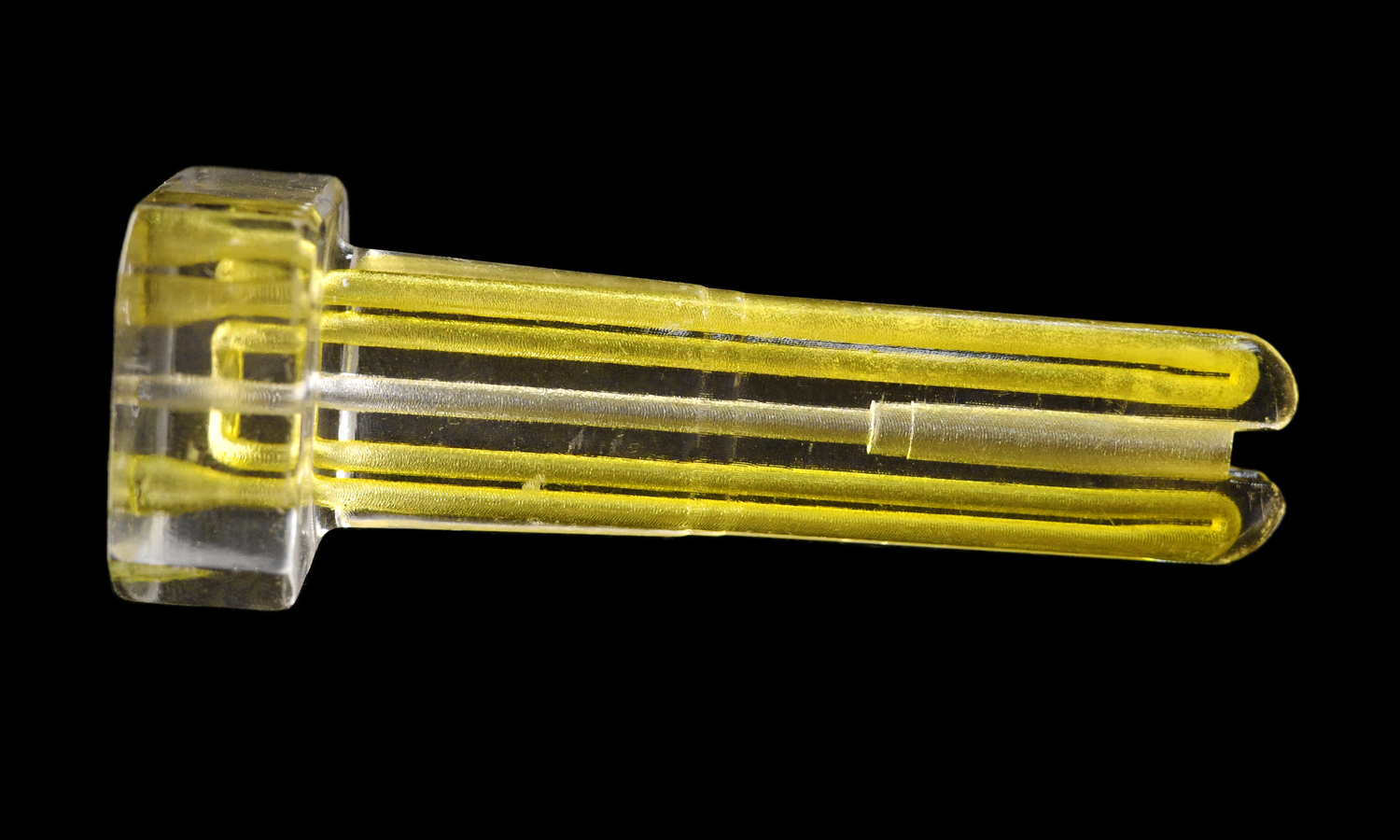

Conformal cooling channels are a solution to this challenge. They are cooling channels that follow the shape of the mold cavity and provide uniform cooling to the part. They can reduce warping, shrinkage, residual stress, and cycle time, as well as improve surface finish and dimensional accuracy.

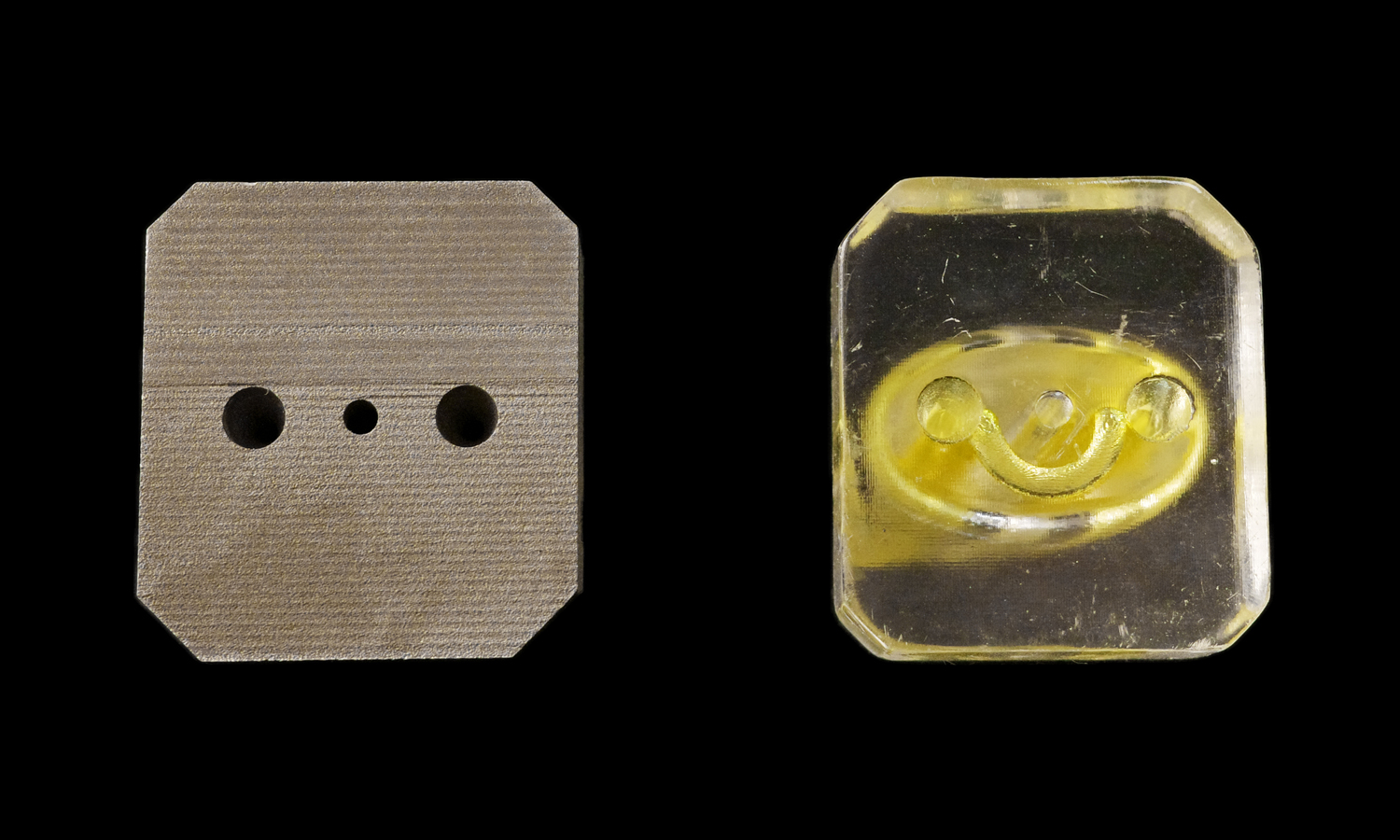

Creating conformal cooling channels is difficult with traditional machining methods, which are limited by the geometry and accessibility of the mold cavity. ThatŌĆÖs why 3D printing technologies, such as SLA and DMLS, can offer a great advantage for creating conformal cooling channels with complex shapes and optimal performance.

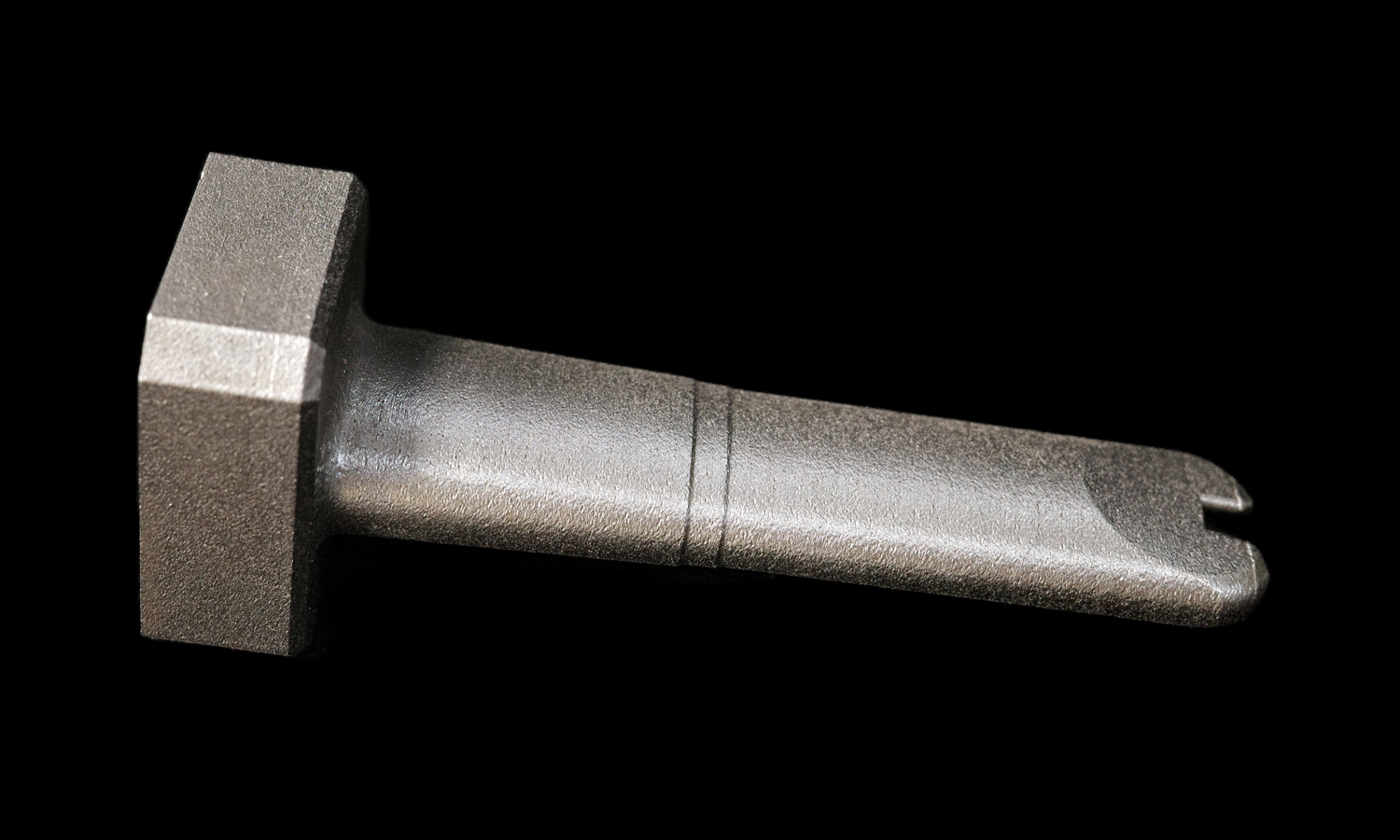

To demonstrate this advantage, we have created two prototypes of injection mold with conformal cooling channels using different 3D printing technologies and materials. The prototype looks like a mini monument, also looks like a lipstick, and there is a groove on its top. We made a transparent one with SLA 3D printing technology and SLA Clear Resin, and made the other one with DMLS technology and SS316L.

That is to say, these two models are printed from the same 3D model, have the same structure, but made with different materials. The transparent one is injected with yellow dye solution to make the conformal cooling channels more obvious. The stainless steel one has a raw grainy surface, and you could see layer lines on the bottom face.

These prototypes showcase the potential of 3D printing for creating injection mold with conformal cooling channels that can improve the quality and efficiency of injection molding process. If you are interested in creating your own prototypes of injection mold with conformal cooling channels, you can contact FacFox, a leading online 3D printing service provider that offers various 3D printing technologies and materials for your prototyping needs.

FacFox can help you design, optimize, and print your prototypes with high quality and fast turnaround time. Visit their website facfox.com or send them an email via info@facfox.com to get a quote today!

Solution

- Step 1: A 3D model of the injection mold with conformal cooling channels was created using CAD software.

- Step 2: The 3D model was sliced into thin layers and converted into a format that can be read by the 3D printers.

- Step 3: The transparent prototype was printed using SLA 3D printing technology and SLA Clear Resin. A laser beam was used to cure the resin layer by layer according to the 3D model.

- Step 4: The transparent prototype was post cured with UV, and then the supporting structures were removed with pliers. It was then sanded and polished with fine-grit sandpaper, sprayed with clear acrylic oil.

- Step 5: The stainless steel prototype was printed using DMLS 3D printing technology and SS316L. A laser beam was used to melt and fuse the metal powder layer by layer according to the 3D model.

- Step 6: The printed prototypes were removed from the build platform and cleaned of any excess material.

- Step 7: The transparent prototype was injected with yellow dye solution to make the conformal cooling channels more visible.

- Step 8: The stainless steel prototype was left with its raw grainy surface, and the layer lines on the bottom face were obvious without sanding and polishing.