Material Other

Quantity 100 pcs

Price Range $100-1,000

Lead Time 7 workdays

Gallery

About Project

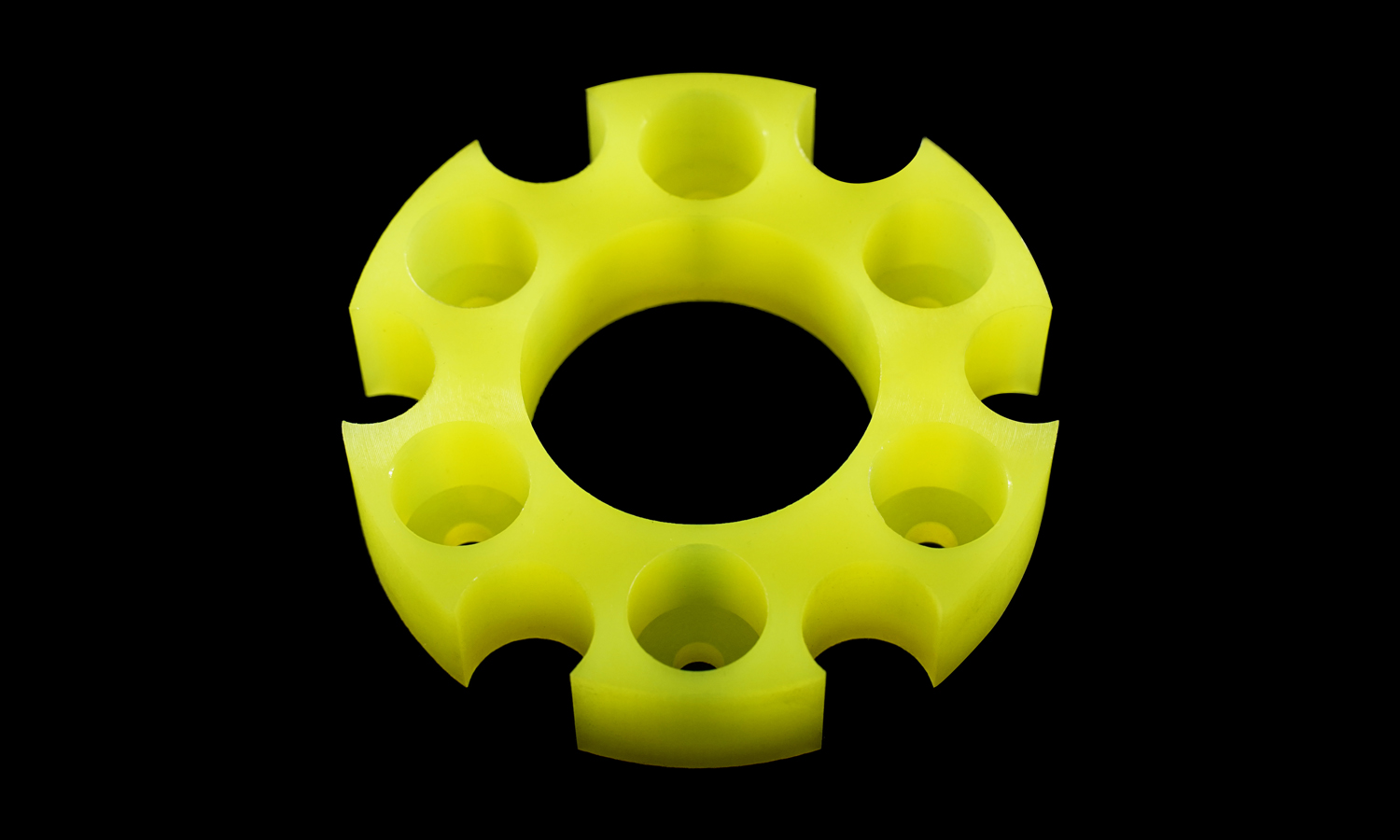

A jaw coupling is a type of mechanical device that connects two shafts and transmits torque. It consists of two hubs with protruding jaws and a spider that fits between them. The spider is made of an elastomeric material, such as polyurethane, that absorbs shock and vibration, compensates for misalignment, and reduces noise.

One of the challenges of jaw couplings is to find a suitable spider material that can withstand high temperatures, pressures, and speeds, as well as resist wear and tear. Polyurethane is a versatile material that can be customized to meet different performance requirements by adjusting its hardness, elasticity, and chemical resistance.

One of our customers, a manufacturer of industrial machinery, needed a custom injection molded polyurethane spider for their jaw couplings. They wanted a snowflake-shaped cushion pad design that would provide better load distribution and reduce stress concentration on the spider. They also wanted a high-quality polyurethane material that would have excellent mechanical properties and durability.

We at FacFox have extensive experience in custom injection molding of polyurethane parts. We can produce complex shapes and geometries with high precision and accuracy. We can also offer a wide range of polyurethane grades and colors to suit different applications and environments.

The result was a custom injection molded polyurethane spider that met our customer’s expectations and satisfaction. The snowflake cushion pad design improved the performance and reliability of the jaw couplings. The polyurethane material provided excellent shock absorption, vibration damping, misalignment compensation, and noise reduction. The parts also had high resistance to abrasion, heat, oil, and chemicals.

Our customer was very happy with our custom injection molding service and the quality of the polyurethane spiders. They reported that the jaw couplings performed better and lasted longer than before. They also appreciated our fast turnaround time and competitive pricing.

If you are looking for custom injection molded polyurethane parts for your applications, look no further than FacFox. We are your one-stop shop for all your polyurethane needs. We can handle any project size and complexity with our expertise and technology. Contact us today to get a free quote and consultation.

Solution

- Step 1: Molds were designed and fabricated based on the 3D model offered by the client. Then the molds was installed on injection molding machine.

- Step 2: The appropriate polyurethane grade and color were selected and prepared for injection.

- Step 3: The pu material was heated and injected into the mold cavity under high pressure and speed, then it was cooled and solidified in the mold.

- Step 4: The mold was opened and the spiders were ejected from the mold.

- Step 5: The spiders was inspected and tested for quality and performance.