- Open Cast Molded Polyurethane Purple Spider for Jaw Couplings

- Independence Day sales is coming soon…We added a giant FDM ABS 3D printer!

Gallery

About Project

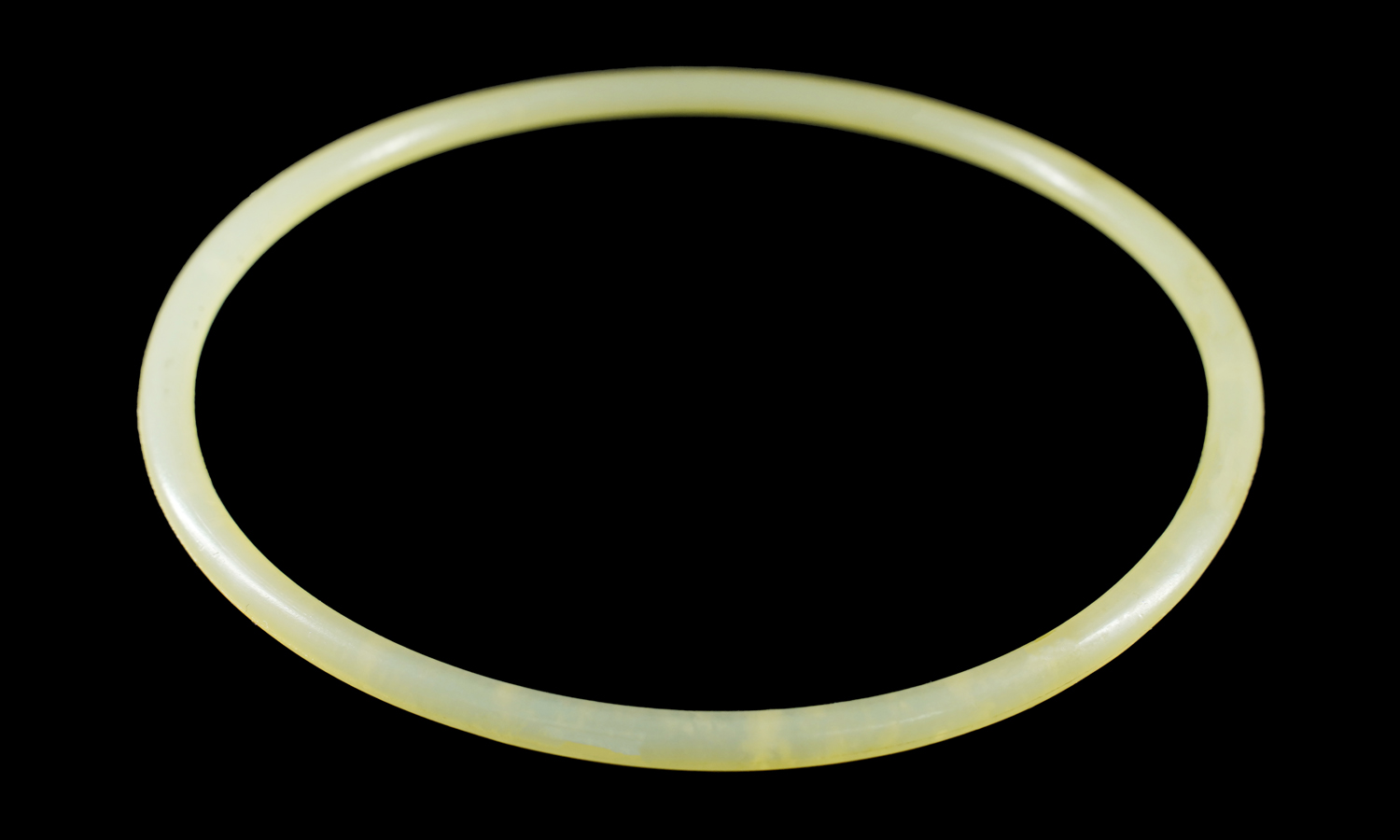

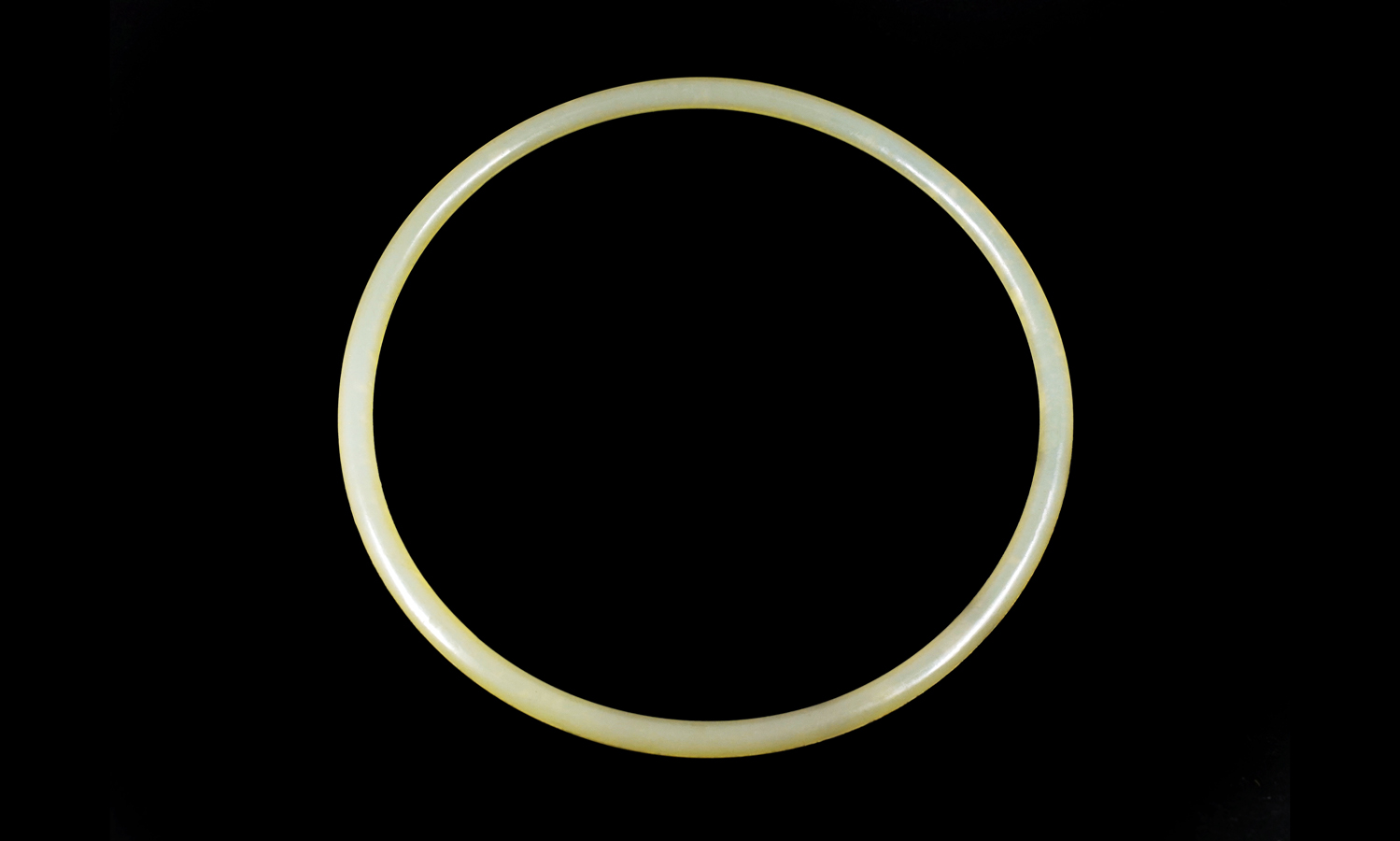

A hydraulic cylinder manufacturer needed thin ring seals for their products. The seals had to withstand high pressure, friction, and temperature changes. The manufacturer also wanted to reduce the cost and time of production.

The manufacturer contacted FacFox, an online manufacturing service provider, to find a solution. FacFox suggested using compression molding to make polyurethane thin ring seals. Compression molding is a technique that involves pouring the liquid polyurethane into a mold, which is placed into a compression press. The press applies heat and pressure to cure the polyurethane and form the ring.

FacFox designed and fabricated the mold according to the specifications of the manufacturer. The mold had multiple cavities to produce multiple rings in one cycle. FacFox also selected a suitable polyurethane formula that had high abrasion resistance, tensile strength, and elasticity.

FacFox produced the polyurethane thin ring seals in a short time and delivered them to the manufacturer. The manufacturer was satisfied with the quality and performance of the seals. The seals fit perfectly into the hydraulic cylinders and provided reliable sealing. The manufacturer also saved money and time by using FacFoxвҖҷs compression molding service.

FacFox is your best partner for making polyurethane rings with lower cost, higher quality, and faster delivery. Contact them today via info@facfox.com and get started on your project!

Solution

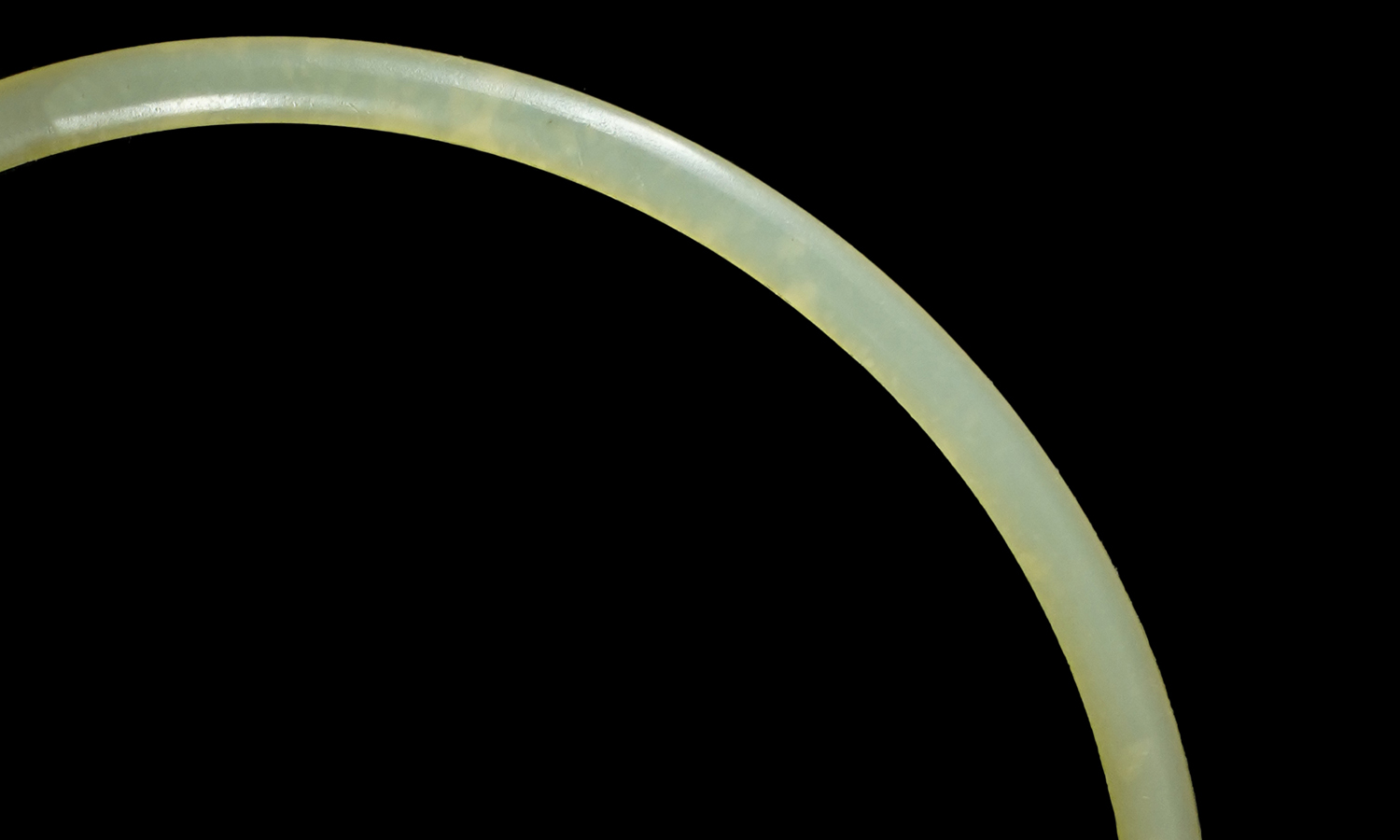

- Step 1: A mold was designed and fabricated according to the specifications of the manufacturer. The mold had multiple cavities to produce multiple rings in one cycle.

- Step 2: A suitable polyurethane formula was selected that had high abrasion resistance, tensile strength, and elasticity.

- Step 3: The liquid polyurethane was poured into the mold, which was placed into a compression press.

- Step 4: The press applied heat and pressure to cure the polyurethane and form the ring. Then the mold was opened and the thin ring seals were removed.

- Step 5: The pu thin ring seals were inspected for quality and performance, packaged and delivered to the manufacturer.