- BinderJet 3D Printed SS316L Perforated Block

- BinderJet 3D Printed SS316L Wireless Earbud Bottom Housing

Gallery

About Project

In the realm of industrial design and architecture, the demand for innovative materials and intricate designs continues to rise. BinderJet 3D printing technology has emerged as a powerful tool to meet these demands, enabling the creation of complex and customizable metal components.

SS316L Textured Panels: A Perfect Blend of Aesthetics and Performance

One such innovation is the 3D-printed SS316L textured panels. This high-performance stainless steel, renowned for its corrosion resistance and strength, is now being transformed into visually striking and functional components.

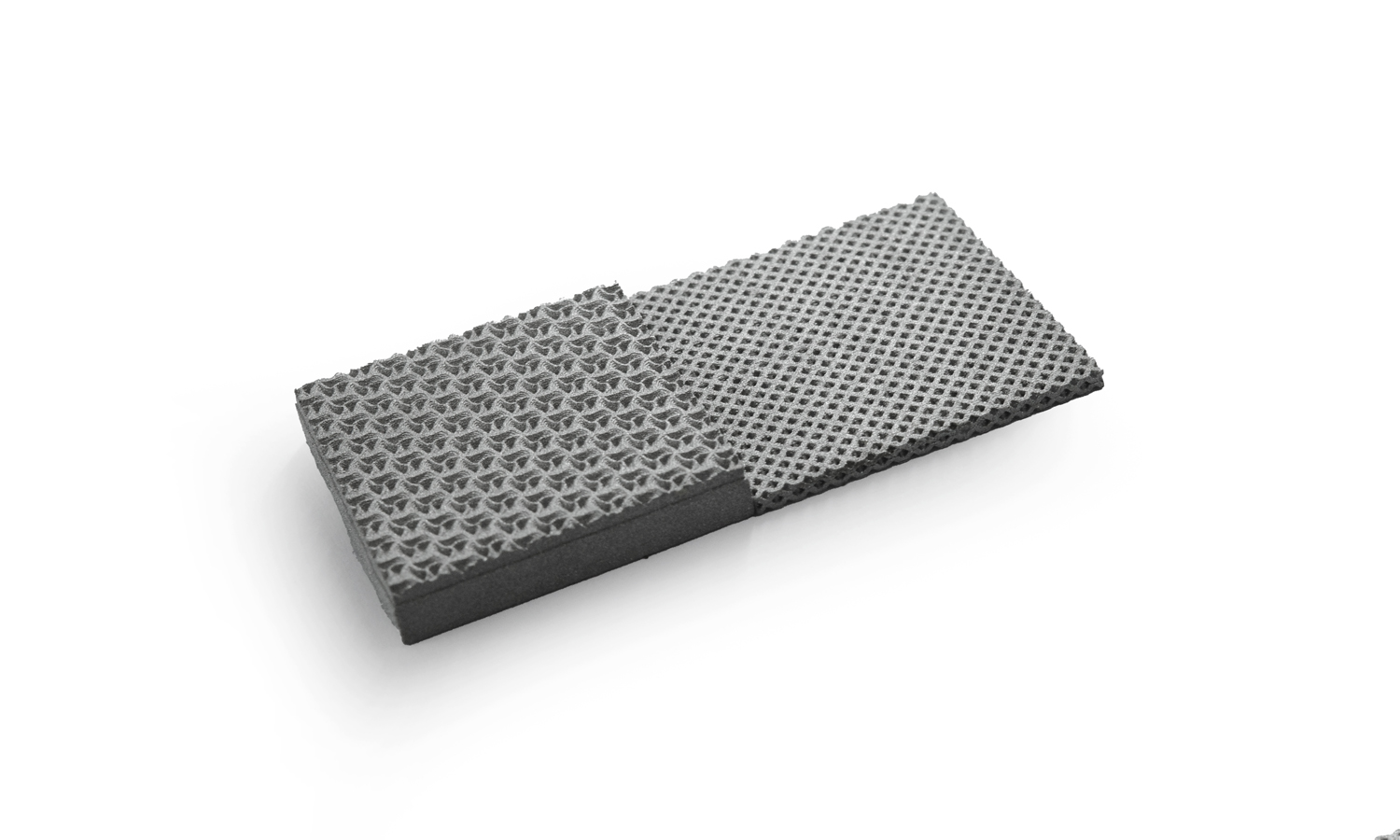

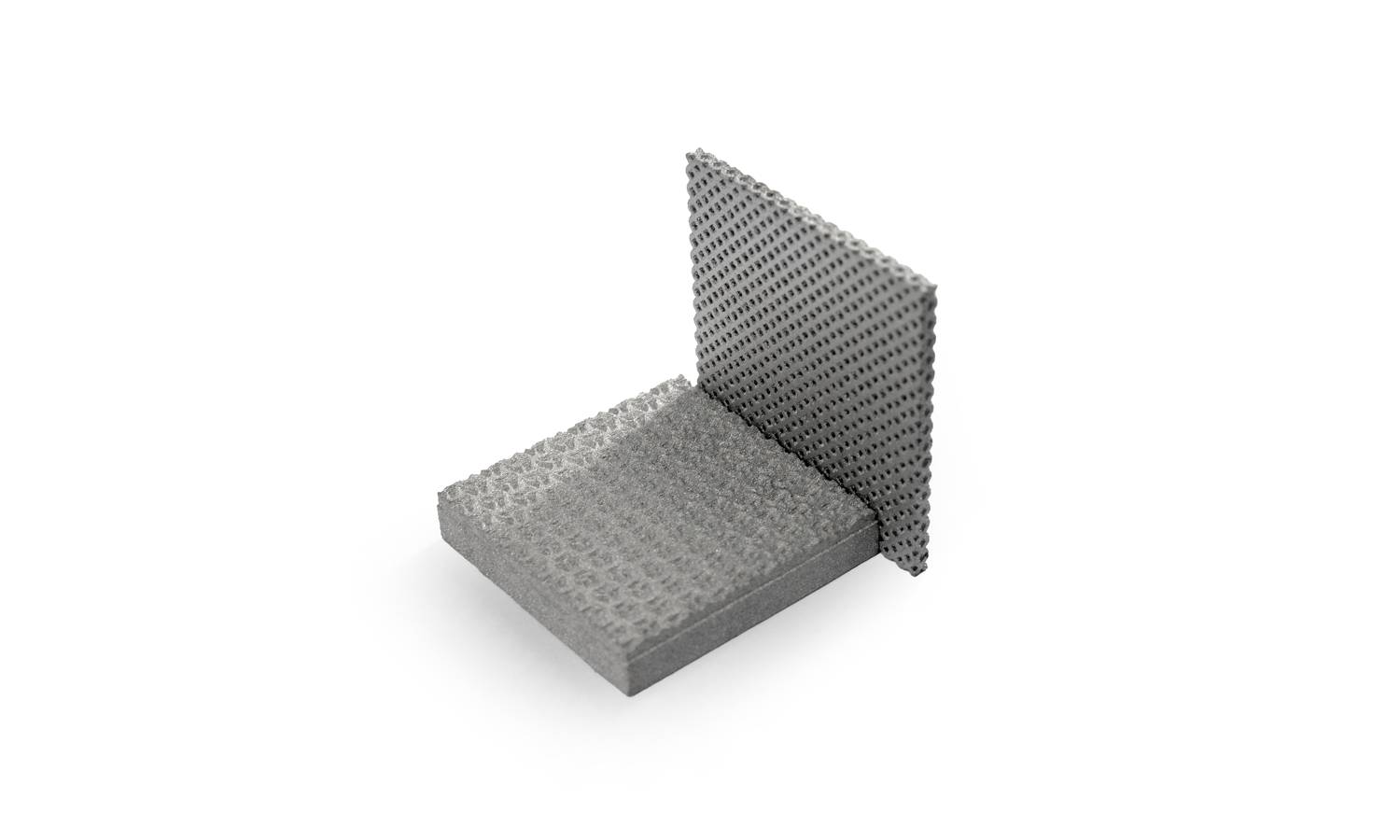

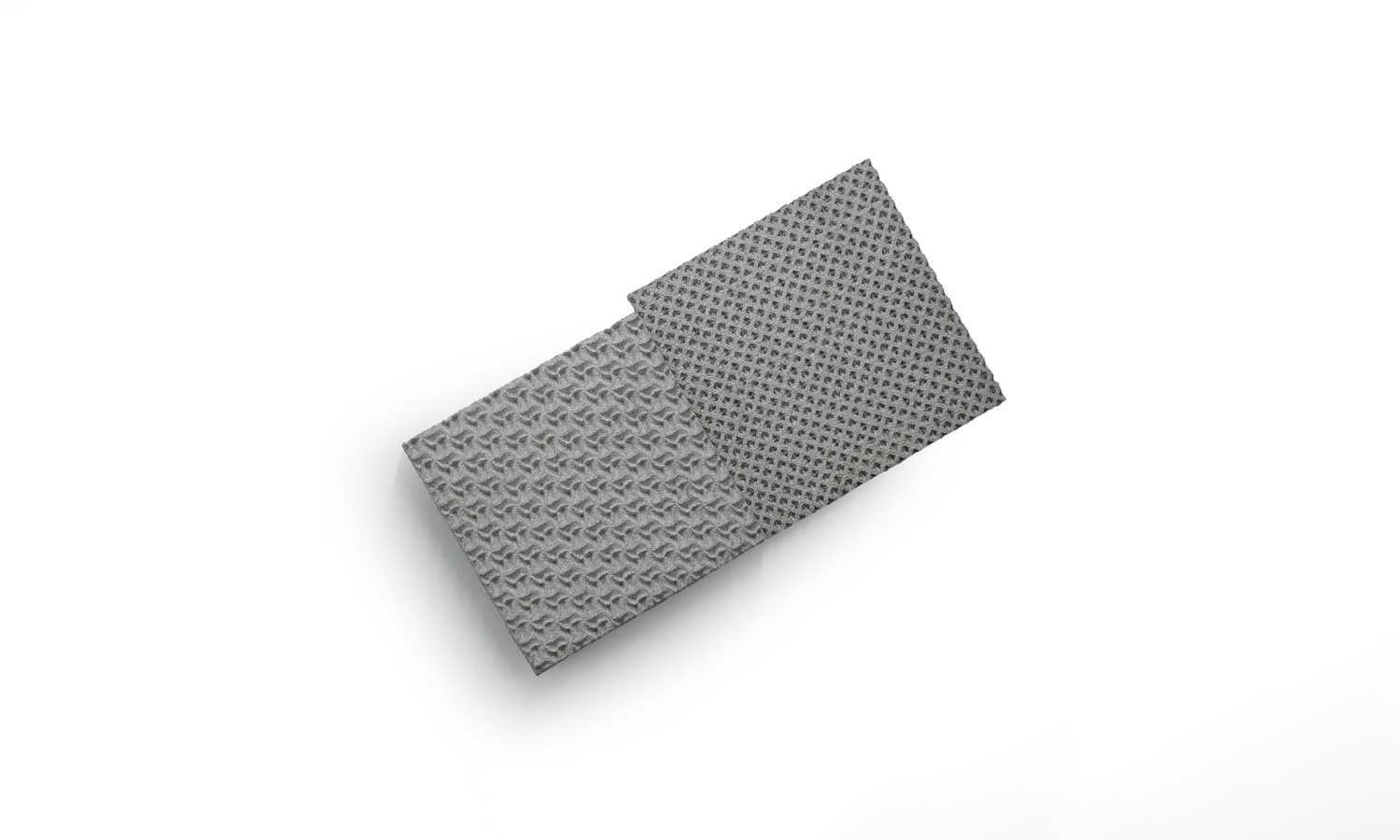

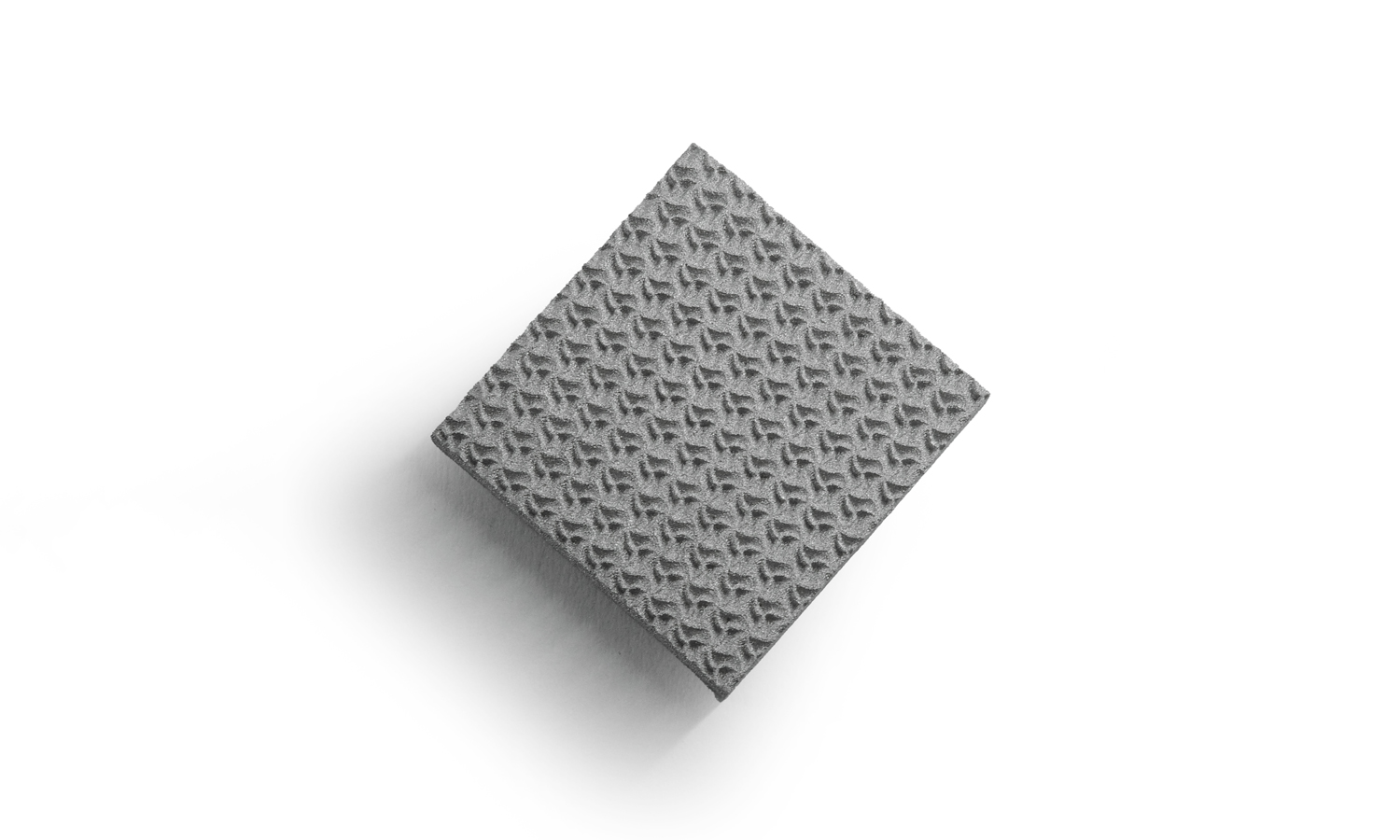

- Thicker Panel: Featuring a captivating surface adorned with repeating, stylized flower-like units, this panel offers a dynamic and tactile experience. The intricate details and unique texture add a touch of elegance and sophistication to any design.

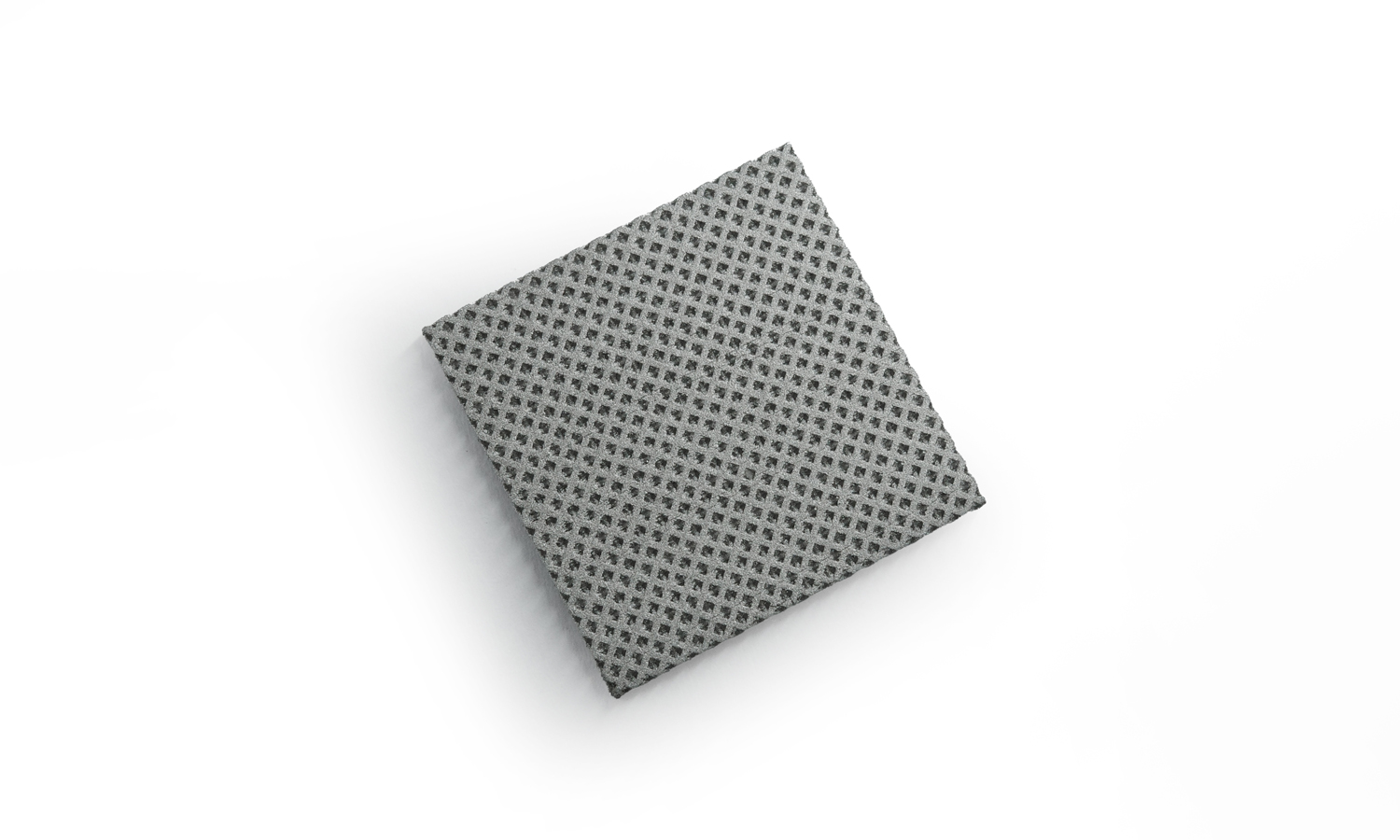

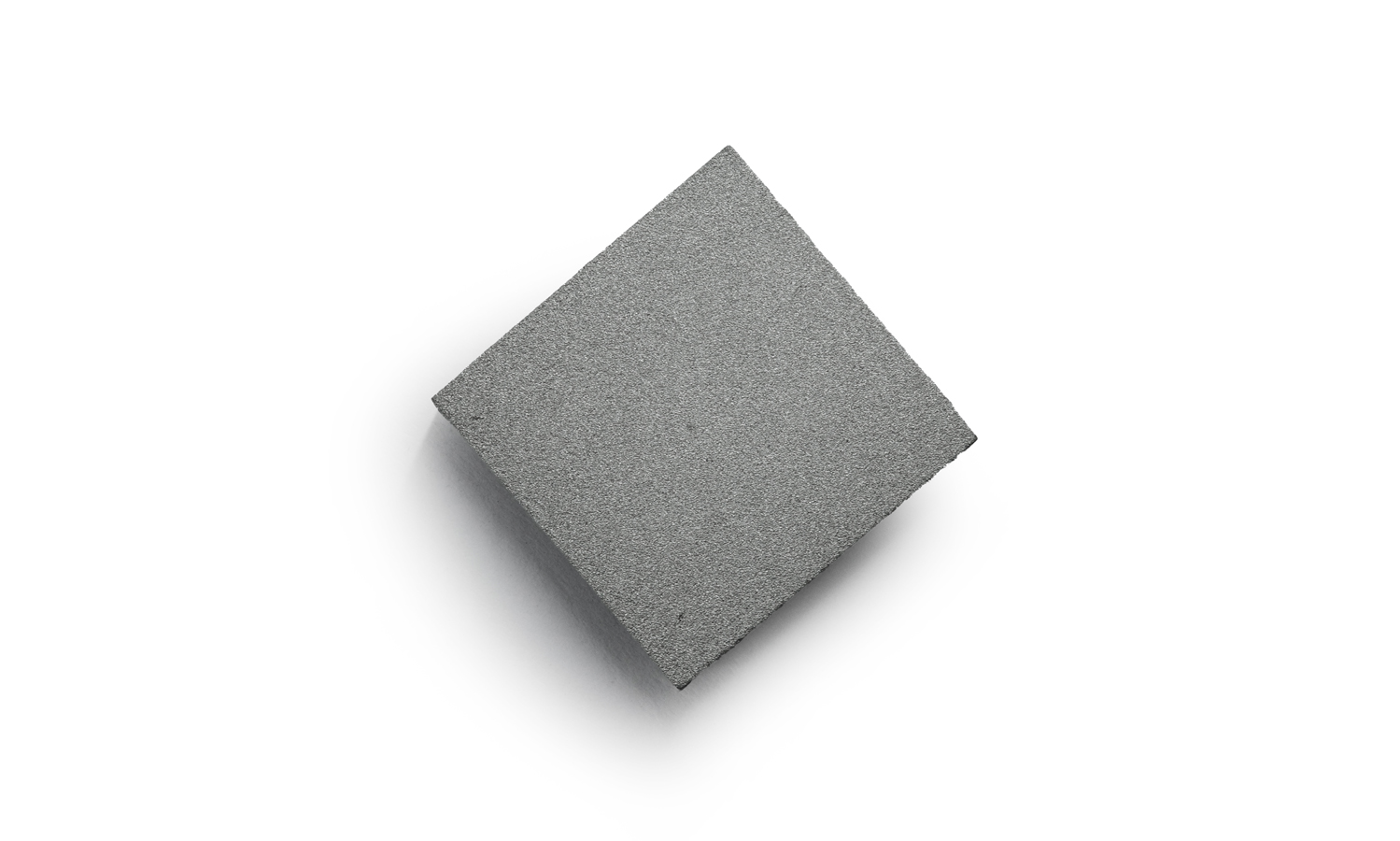

- Thinner Panel: With a more subdued yet equally intriguing spaced-out grid-like structure, this panel provides a clean and modern aesthetic. The subtle texture adds depth and visual interest, enhancing the overall design.

Applications Across Industries

These 3D printed SS316L textured panels have a wide range of applications across various industries, including:

- Architecture and Interior Design: Create stunning wall cladding, decorative screens, and unique architectural elements.

- Automotive and Aerospace: Design intricate components with complex geometries and enhanced surface properties.

- Medical Devices: Develop customized implants and surgical tools with improved biocompatibility and performance.

Experience the Future of Metal 3D Printing with FacFox

FacFox is at the forefront of metal 3D printing technology, offering a comprehensive range of services to bring your designs to life. Our state-of-the-art equipment and skilled engineers ensure the highest quality and precision in every project.

Ready to explore the possibilities of 3D-printed SS316L textured panels? Contact FacFox today to discuss your project requirements.

Solution

- Step 1: 3D Model Creation and Preparation. A detailed 3D model of the desired textured panel was created using CAD software. The model was then optimized for 3D printing, ensuring accurate dimensions and surface details.

- Step 2: Powder Bed Preparation. A thin layer of stainless steel (SS316L) powder was evenly distributed across the build platform.

- Step 3: Binder Jetting. A printhead selectively deposited a liquid binder onto the powder layer, bonding the particles together to form the desired shape. This process was repeated layer by layer, gradually building up the 3D structure.

- Step 4: Debinding. The printed part was subjected to a debinding process to remove the binder. This was typically achieved through thermal debinding or solvent-based debinding.

- Step 5: Sintering. The debinded part was sintered in a high-temperature furnace. This process fused the metal powder particles together, creating a solid, dense metal component.

- Step 6: Quality Inspection. The final part was inspected to ensure it met the specified quality standards, including dimensional accuracy, surface finish, and mechanical properties.