- SLA 3D Printed High-temp Resin 238Ōäā Fluid System Part

- SLM 3D Printed Brass with Gyroid and Perforated Structure

Material Metal

Quantity 1 pcs

Price Range $1-100

Lead Time 4 workdays

Gallery

About Project

The relentless demand for increased processing power in GPUs (Graphics Processing Units) brings with it a significant challenge: heat dissipation. Traditional manufacturing methods often impose limitations on the complexity and efficiency of heat sink designs. But what if we could break those barriers?

Introducing the future of GPU cooling: SLM 3D printed pure copper heat sinks.

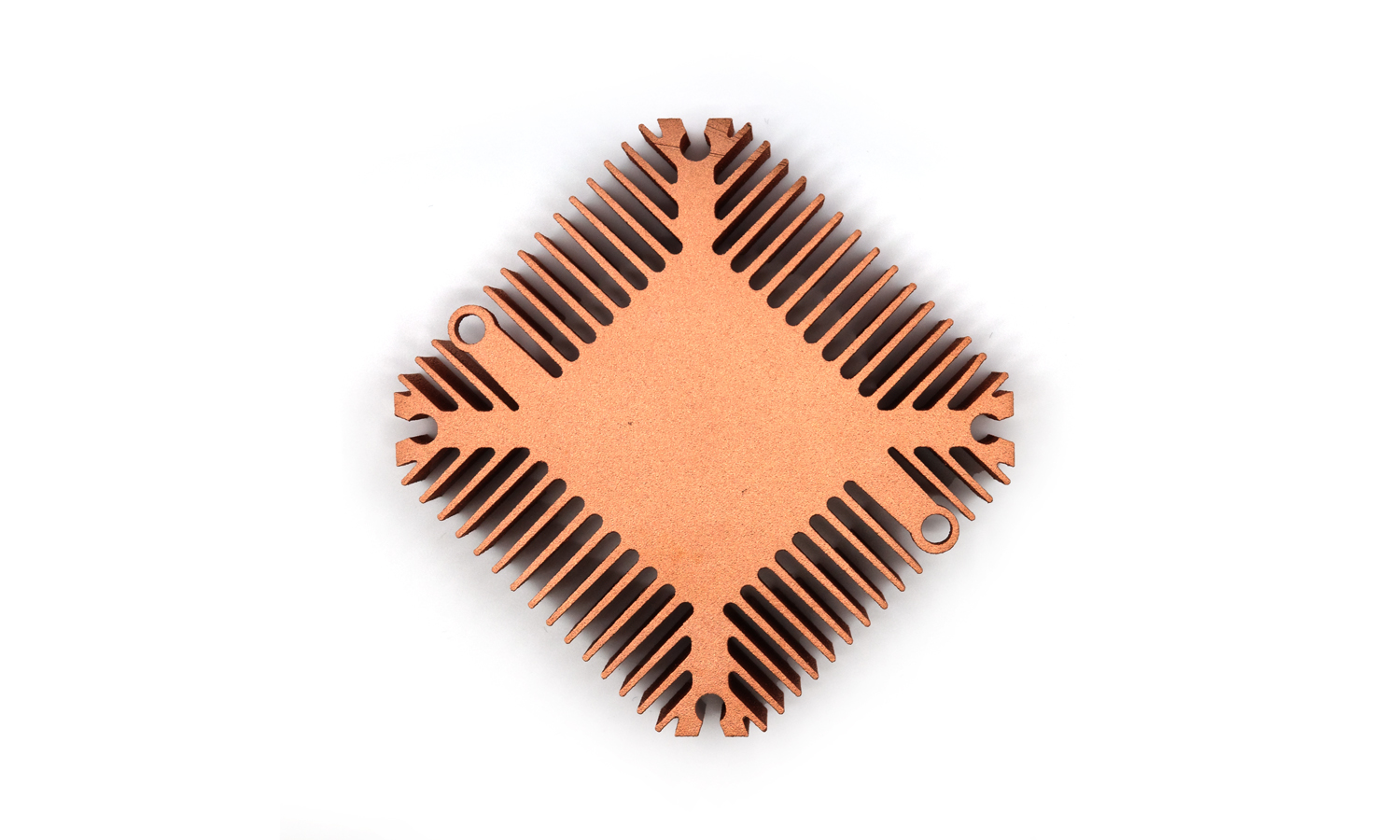

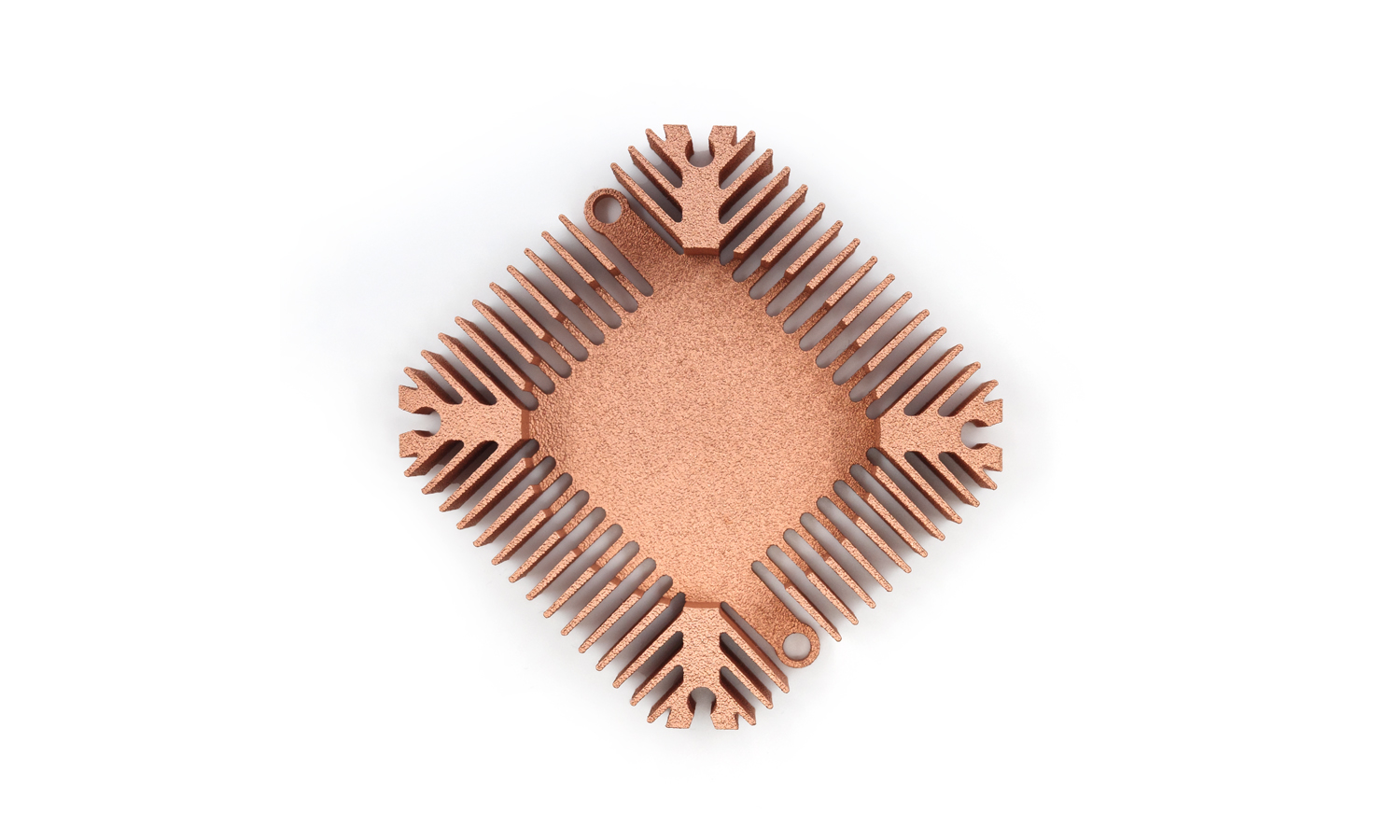

The component featured in the image is a prime example. While it showcases a radial fin design, the true potential of 3D printing lies in its ability to create far more intricate and optimized structures.

The part you see is a heat sink, a crucial component in a GPU cooling system. It’s crafted from pure copper, a material renowned for its exceptional thermal conductivity. Copper efficiently draws heat away from the GPU die, preventing overheating and ensuring optimal performance. The radial fin design increases the surface area exposed to airflow, further enhancing heat dissipation.

Traditional heat sinks are often manufactured using extrusion or stamping, which can restrict design freedom. Selective Laser Melting (SLM), a powder bed fusion 3D printing technology, offers unparalleled design flexibility.

- Design Freedom: SLM allows for the creation of complex internal channels, lattice structures, and optimized fin geometries that are impossible to achieve with conventional methods. This enables the design of heat sinks with significantly improved thermal performance and reduced weight.

- Pure Copper Printing: Printing with pure copper is challenging due to its high reflectivity and thermal conductivity. However, advancements in laser technology, particularly the use of 532nm green lasers, have made it possible to overcome these hurdles. Green lasers offer better absorption by copper powder, leading to more efficient melting and higher density parts.

- Enhanced Performance: SLM 3D printed copper heat sinks can be tailored to the specific thermal requirements of different GPUs, resulting in more effective cooling and improved overall system performance.

Why Choose SLM 3D Printed Copper Heat Sinks?

- Superior Thermal Performance: Copper’s high conductivity combined with optimized 3D printed designs leads to more efficient heat dissipation.

- Design Optimization: SLM enables the creation of complex and lightweight heat sink structures tailored to specific applications.

- Customization: 3D printing allows for the production of custom heat sinks for various GPU models and cooling systems.

- Improved Reliability: Effective cooling ensures stable GPU operation and extends the lifespan of the components.

Ready to revolutionize your GPU cooling solutions?

FacFox is at the forefront of advanced manufacturing, offering cutting-edge 532nm green laser pure copper 3D printing services. Our expertise in SLM technology allows us to produce high-quality, high-performance copper heat sinks that meet the most demanding requirements. Whether you need custom prototypes or production-grade parts, FacFox can deliver. Contact us today to explore the possibilities of 3D printed pure copper heat sinks and take your thermal management to the next level!

Solution

- Step 1: The 3D model of the heat sink was designed using CAD (Computer-Aided Design) software.

- Step 2: The CAD file was converted into an STL (Stereolithography) file, the standard file format for 3D printing.

- Step 3: High-purity copper powder, with carefully controlled particle size and shape, was selected and prepared.

- Step 4: The copper powder was evenly spread in a thin layer onto the build platform within the SLM machine.

- Step 5: A 532nm green laser, precisely controlled by computer instructions, was used to selectively melt and fuse the copper powder particles together, following the cross-sectional data from the STL file.

- Step 6: After each layer was completed, the build platform was lowered by a small increment, and another layer of copper powder was spread over the previous one.

- Step 7: The laser melting process was repeated layer by layer until the entire heat sink was built.

- Step 8: Once the printing process was finished, the build chamber was allowed to cool.

- Step 9: The solidified heat sink, embedded in the unsintered copper powder, was carefully removed from the build platform.

- Step 10: The excess, loose copper powder was removed from the heat sink using techniques such as brushing, air blasting, or vibration.

- Step 11: The heat sink may have undergone post-processing steps, such as heat treatment, to relieve internal stresses and improve its mechanical properties.

- Step 12: Surface finishing processes, such as machining, polishing, or coating, may have been applied to achieve the desired surface finish and dimensional accuracy.