Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 1 workdays

Gallery

About Project

Are you looking for a way to protect your sensitive electronics from static discharge? Do you need a custom-made cover that fits your specific design and requirements? If so, you might be interested in this SLA 3D-printed Formlabs ESD Resin Electronics Cover.

This cover is made from Formlabs ESD Resin, a static-dissipative material that safely dissipates static buildup that can damage electronic components.┬ĀESD Resin has a surface resistivity of 10 5 – 10 8 Ohms/sq, which means it is more conductive than other Formlabs resins and allows electric charges to flow in a controlled manner.┬ĀESD Resin also has high toughness, impact strength, and heat resistance, making it ideal for producing robust custom parts that comply with ESD safety standards.

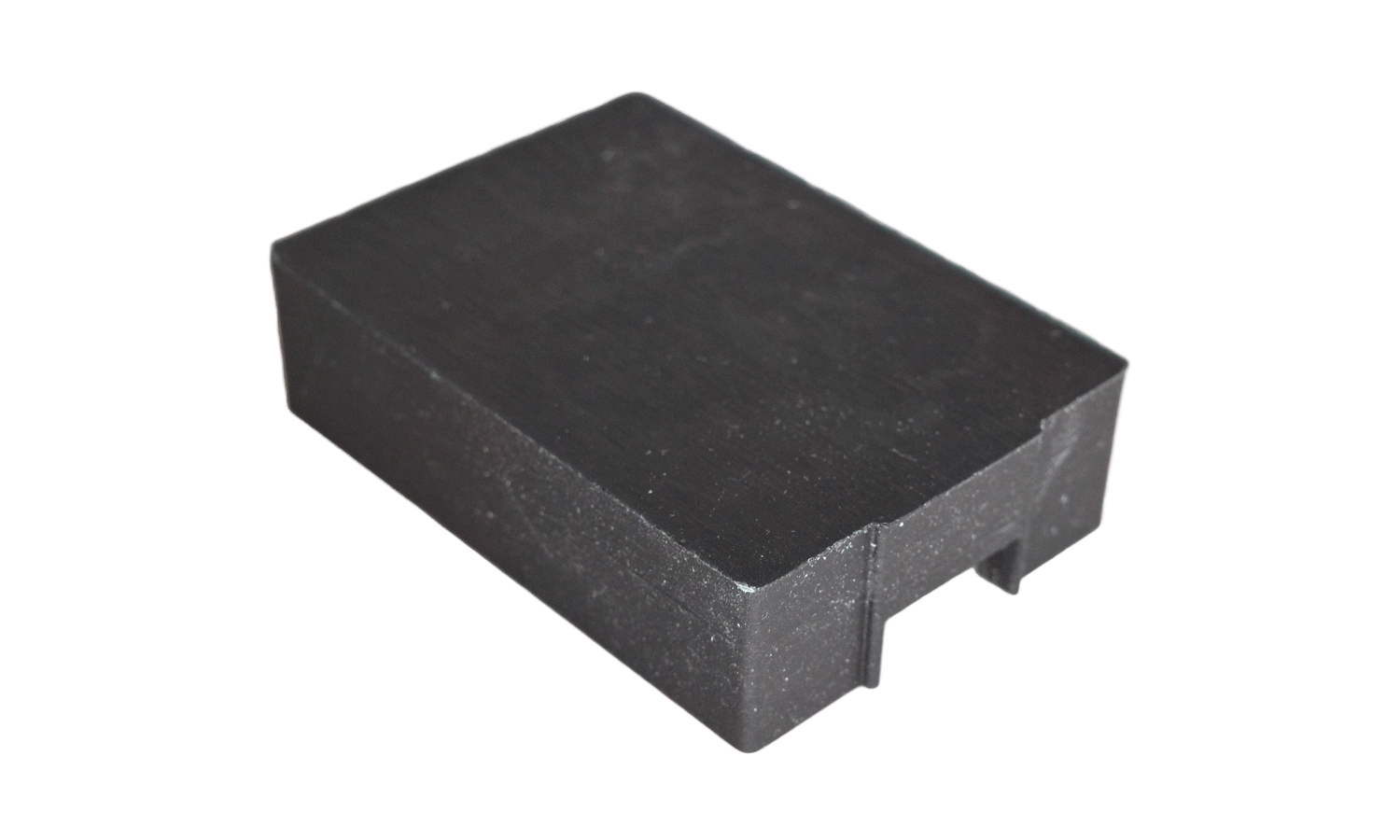

The cover has a simple rectangular shape with rounded corners and edges. It has letters ŌĆ£ESDŌĆØ printed on the bottom inside to indicate the material type. There are two grooves, one on each shorter side, that allow the cover to be easily attached and detached from the base. And there are four small pillars in each corner that provide support and stability for the cover. The cover measures 100 x 50 x 20 mm and weighs 30 grams.

We donŌĆÖt know what this cover is used for, but considering the materialŌĆÖs properties, it should be a cover for some kind of electronic device that needs protection from static discharge. Maybe it is a circuit board, a sensor, a controller, or something else. Whatever it is, we are sure that this cover will do its job well.

If you want to order this cover or create your own custom design, you can contact FacFox, a professional online manufacturing service provider. FacFox can help you with SLA 3D printing, as well as other processes such as CNC machining, injection molding, sheet metal fabrication, and more. FacFox has a team of experts who can assist you with your project from start to finish. You can upload your 3D model to their website and get an instant quote and feedback. You can also choose from a wide range of materials, colors, finishes, and post-processing options. FacFox guarantees high quality, fast delivery, and competitive prices for your manufacturing needs.

Visit FacFoxŌĆÖs website┬Āhere┬Āto learn more about their services and capabilities. You can also check out their case studies┬Āhere┬Āto see some examples of their previous work. Whether you need one piece or thousands of pieces, FacFox can help you turn your idea into reality.

Solution

- Step 1: A 3D model of the cover was designed using CAD software and exported in a 3D printable file format (STL or OBJ).

- Step 2: The 3D model was imported into a 3D slicer software that converted it into a series of thin layers and generated a set of instructions for the SLA 3D printer.

- Step 3: The SLA 3D printer used a bottom-up method, where the build platform was lowered into a resin tank filled with Formlabs ESD Resin, a static-dissipative material.

- Step 4: A UV laser beam was directed by two mirrors (galvanometers) on the X and Y axes to selectively cure the resin on the bottom of the tank, forming the first layer of the cover.

- Step 5: The build platform was lifted slightly to allow a thin layer of resin to flow beneath it, and then lowered back to the previous position.

- Step 6: The process was repeated until the entire cover was completed, with each layer being bonded to the previous one.

- Step 7: The cover was then detached from the build platform and transferred to a post-processing station, where it was washed with isopropyl alcohol (IPA) to remove any excess resin.

- Step 8: The cover was then cured in a UV chamber to enhance its mechanical properties and finalize polymerization.

- Step 9: The cover was then inspected for quality and accuracy, and any support structures were removed using tools such as pliers or cutters.