- Full-Size SU7 Ultra Car Model Made with 3D Printing

- Unlock Unmatched Precision with FacFoxŌĆÖs LCD 3D Printing Service

Gallery

About Project

When evaluating metal additive manufacturing, the choice of technology directly impacts the precision, surface finish, and overall quality of the final part. Here, we compare two stainless steel 316L components produced by different processes: Micro-LPBF/SLM and Binder Jetting with polishing.

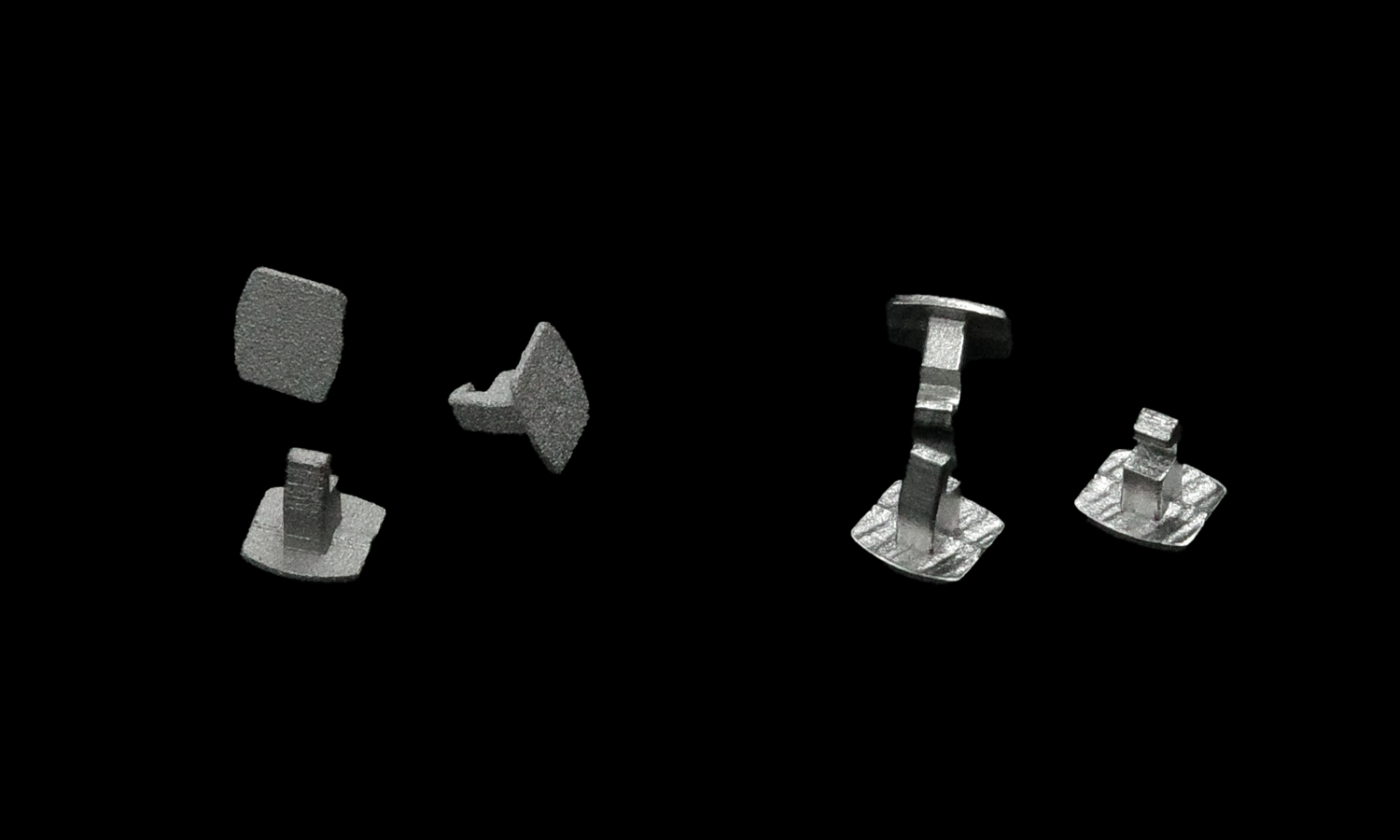

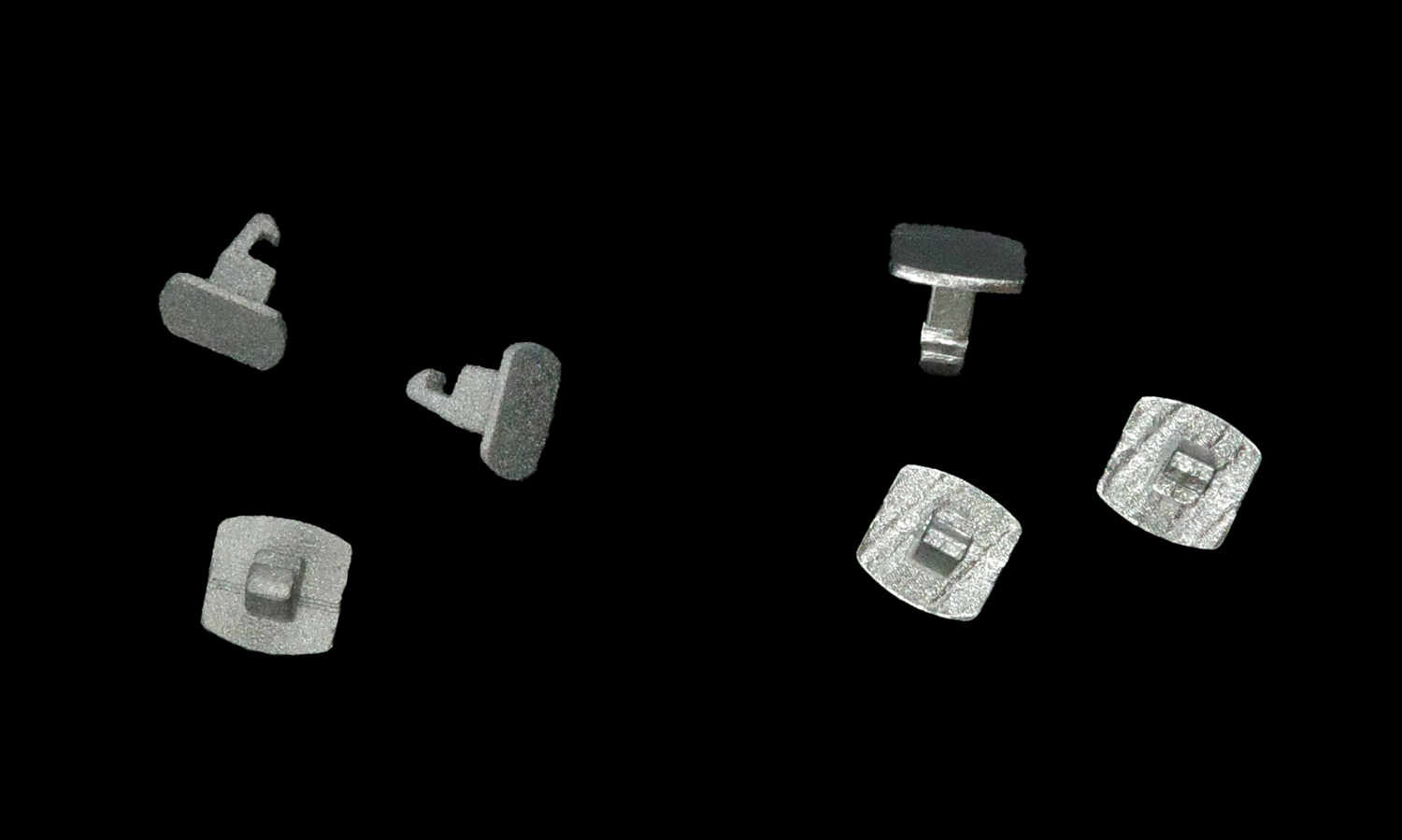

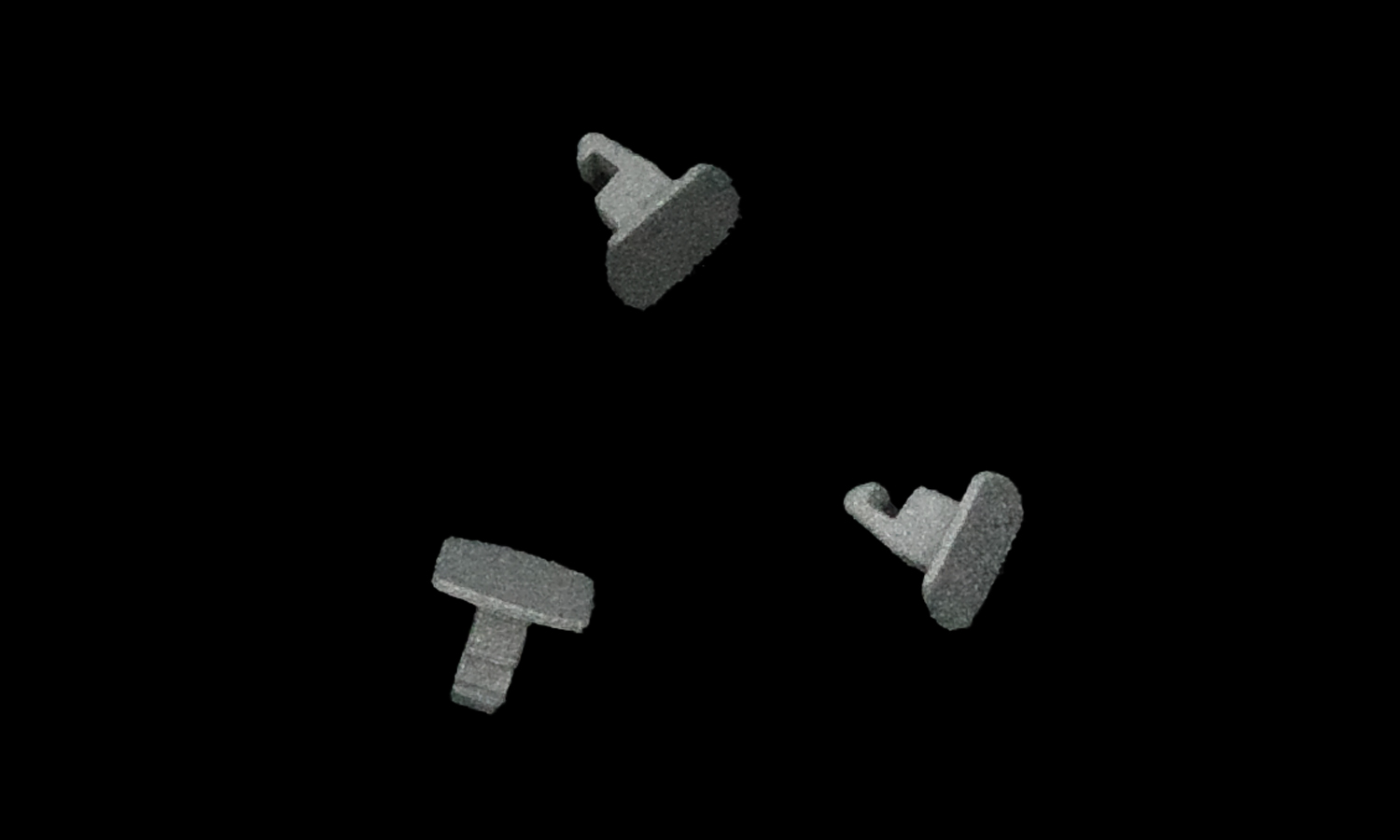

Micro-LPBF/SLM in SS316L

Micro-Laser Powder Bed Fusion (Micro-LPBF, also known as micro-SLM) uses a highly focused laser to selectively fuse ultra-fine metal powders. This process achieves exceptional resolution and surface quality. In the SS316L samples, fine edges and tiny features are sharply defined, with minimal stair-stepping visible. Even without extensive post-processing, the matte surface finish is uniform and consistent, making this technology ideal for micro-mechanical components, medical devices, and precision engineering parts where micron-level accuracy matters.

Binder Jetting + Polishing

Binder Jetting builds parts by depositing a liquid binder onto a powder bed, followed by sintering and post-processing. While this method enables faster and more cost-effective production for larger batches, the initial surface roughness requires polishing to improve appearance. After polishing, the parts gain a reflective shine, but fine details and sharp edges become softened, and surfaces may still appear slightly uneven compared to Micro-LPBF. Binder Jetting is well-suited for applications where throughput and aesthetics are prioritized over ultra-fine accuracy.

Choosing the Right Approach

Both processes have their strengths. Micro-LPBF/SLM in SS316L excels in high-resolution applications, delivering crisp details and reliable dimensional accuracy. Binder Jetting with polishing offers scalable production with smoother visual appeal, though it sacrifices micro-precision. The optimal choice depends on whether accuracy or productivity is the primary driver.

At FacFox, we provide a full spectrum of metal 3D printing services, from high-precision Micro-LPBF/SLM in stainless steel and other alloys to efficient Binder Jetting for scalable production. Complemented by professional post-processing-such as polishing, machining, and coating-we ensure your parts meet the highest standards of both functionality and finish. Whether you need fine micro-features or cost-effective production runs, FacFox delivers metal parts tailored to your project needs.

Solution

Micro-LPBF/SLM (SS316L) – Manufacturing Process

- Step 1: CAD preparation and DfAM checksThe 3D model was inspected for thin walls, overhangs, and tolerances suited to micro-LPBF. Sharp features were preserved and fillets were applied where needed.

- Step 2: Orientation, supports, and slicingThe part was oriented to minimize stair-stepping on critical faces. Micro supports were generated, and the build was sliced at an appropriate micro layer thickness.

- Step 3: Powder and machine preparationSS316L powder with a fine particle distribution was verified for flowability and moisture, the build chamber was cleaned, and the inert atmosphere was established.

- Step 4: Laser powder bed fusionLayers of powder were spread and selectively fused by the laser according to toolpaths. Process parameters were applied to control energy density and minimize distortion.

- Step 5: Cool-down and de-powderingAfter build completion, the chamber was cooled under inert gas. Loose powder was removed by gentle blasting and vacuum extraction to expose the green parts on the plate.

- Step 6: Stress relief heat treatmentA stress-relief cycle was performed to reduce residual stresses and stabilize micro-features.

- Step 7: Part release and support removalParts were separated from the build plate by precision cutting. Micro supports were removed using fine mechanical methods under magnification.

- Step 8: Surface refinement (as required)Light bead blasting or micro-polishing was performed to unify the matte surface while preserving edges and detail.

- Step 9: Dimensional inspection and finishingCritical dimensions were measured (e.g., via optical or CMM inspection). Any minor burrs were removed and parts were cleaned and dried for presentation.

Binder Jetting (SS316L) + Polishing – Manufacturing Process

- Step 1: CAD preparation and scalingThe 3D model was adjusted for anticipated sintering shrinkage and checked for uniform wall thickness to promote even densification.

- Step 2: Build setup and slicingParts were oriented to balance printability and depowder access. The job was sliced for binder jet deposition.

- Step 3: Powder loading and print executionSS316L powder was loaded and leveled. Binder was selectively deposited to form each layer, and the build was completed to produce “green” parts.

- Step 4: In-box curingThe green parts were thermally cured to strengthen binder bridges prior to handling.

- Step 5: DepowderingUnbound powder was removed using air and media tools, and green parts were transferred to debinding fixtures.

- Step 6: Debinding and sinteringBinder removal was performed under controlled atmosphere, followed by high-temperature sintering to densify the parts according to the alloy profile.

- Step 7: Optional sizing or straighteningIf required, light fixturing or sizing was applied after sintering to correct minor distortion.

- Step 8: Mechanical finishingPolishing operations (tumbling, vibratory finishing, and/or manual polish) were performed to increase surface reflectivity.

- Step 9: Final inspection and cleaningKey dimensions and features were inspected. Parts were cleaned, dried, and prepared for presentation.