- CNC Machined Precision Stepper Motor Housing

- Customize Motorcycle Taillight Component with 3D Printing and CNC

Gallery

About Project

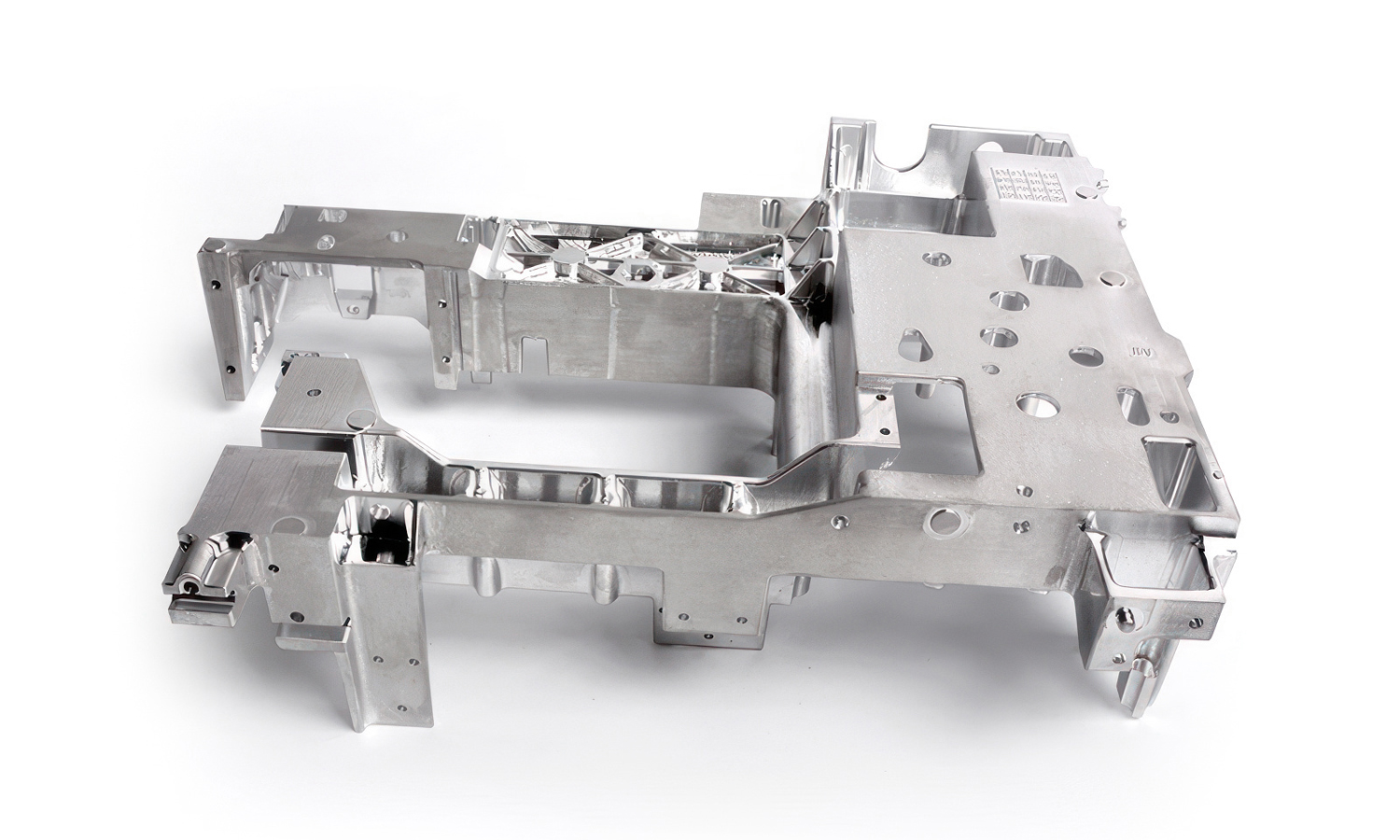

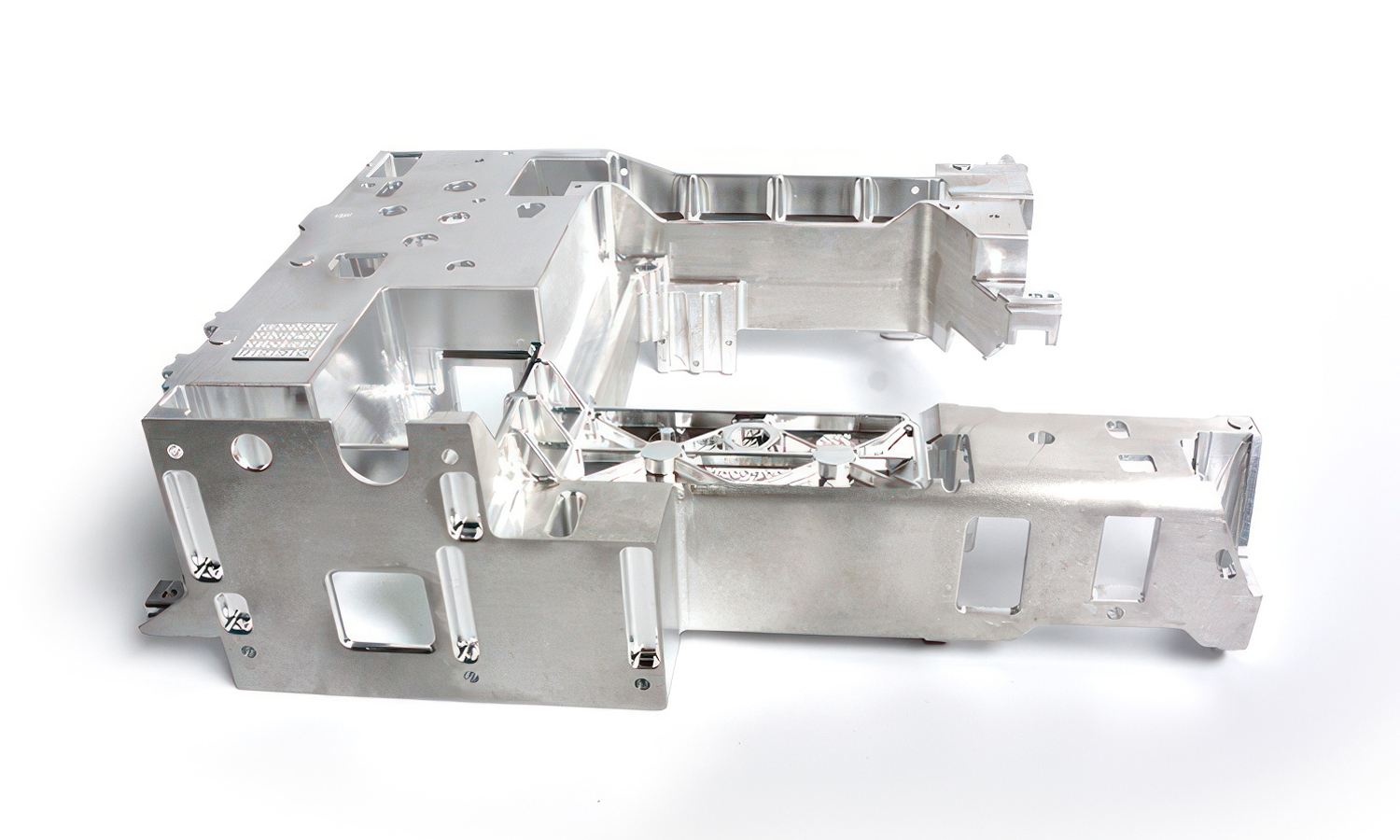

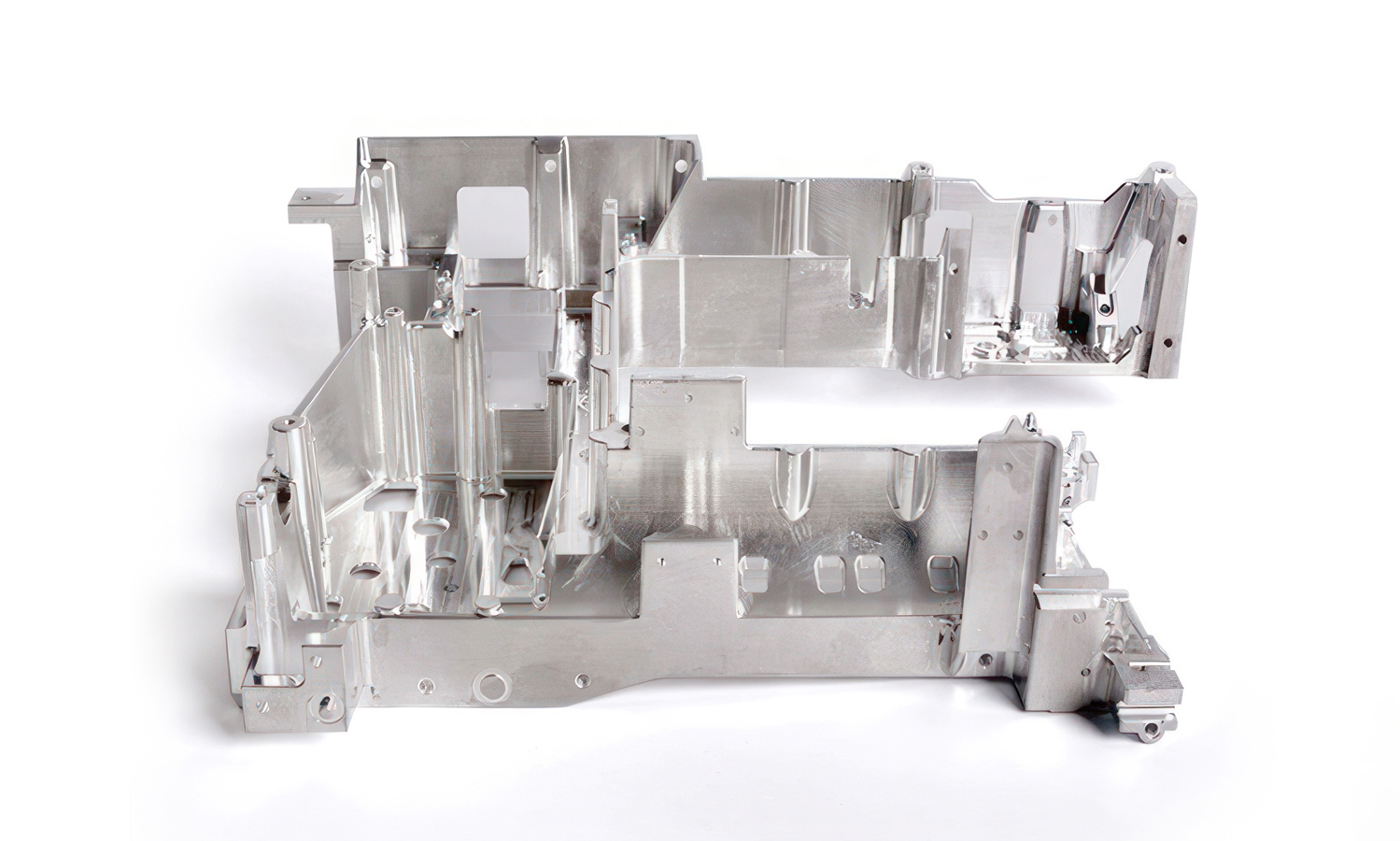

When it comes to precision engineering, the demand for lightweight yet structurally robust components continues to rise-particularly in sectors like aerospace, robotics, electronics, and medical equipment. The showcased aluminum alloy chassis exemplifies what modern CNC machining is capable of: combining intricate design with high-strength performance.

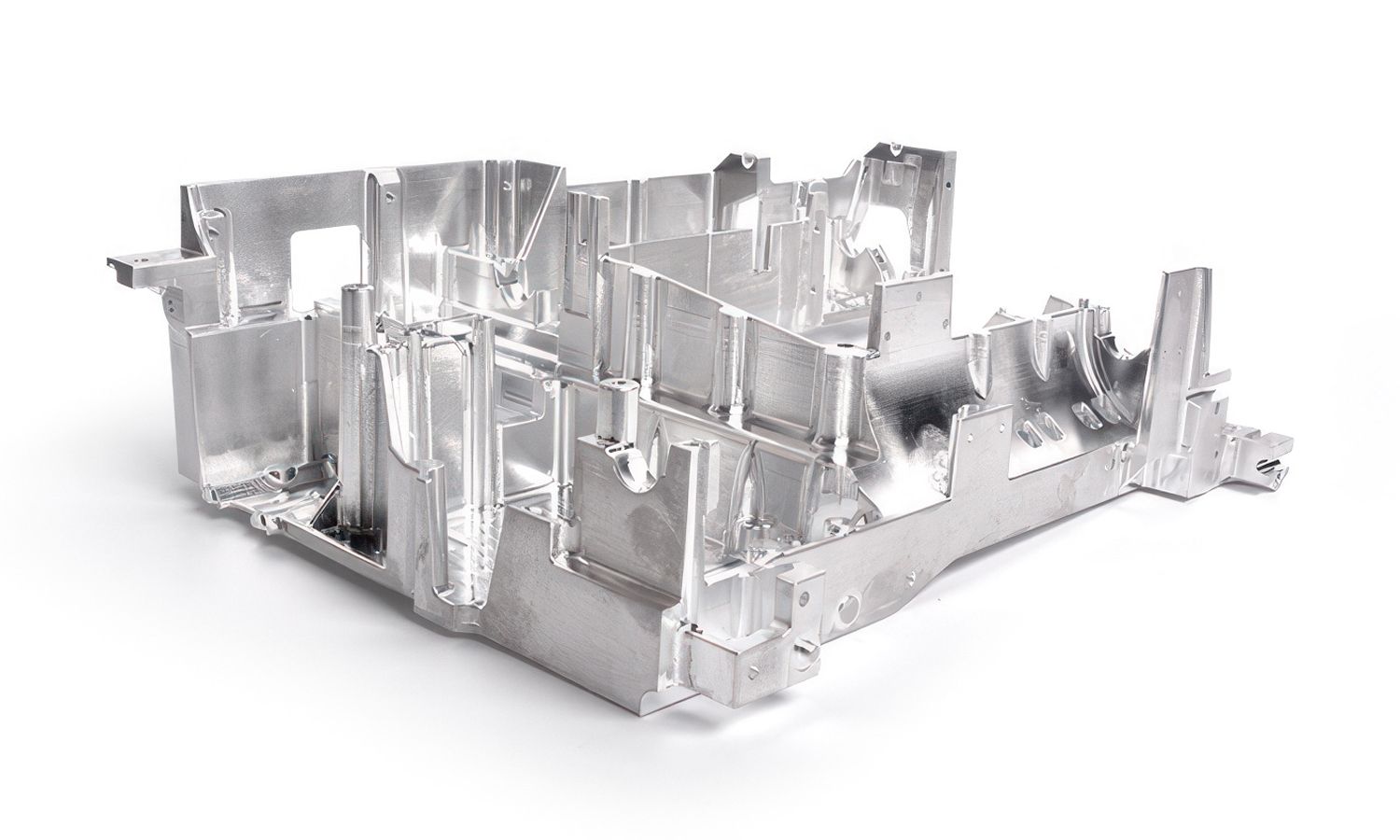

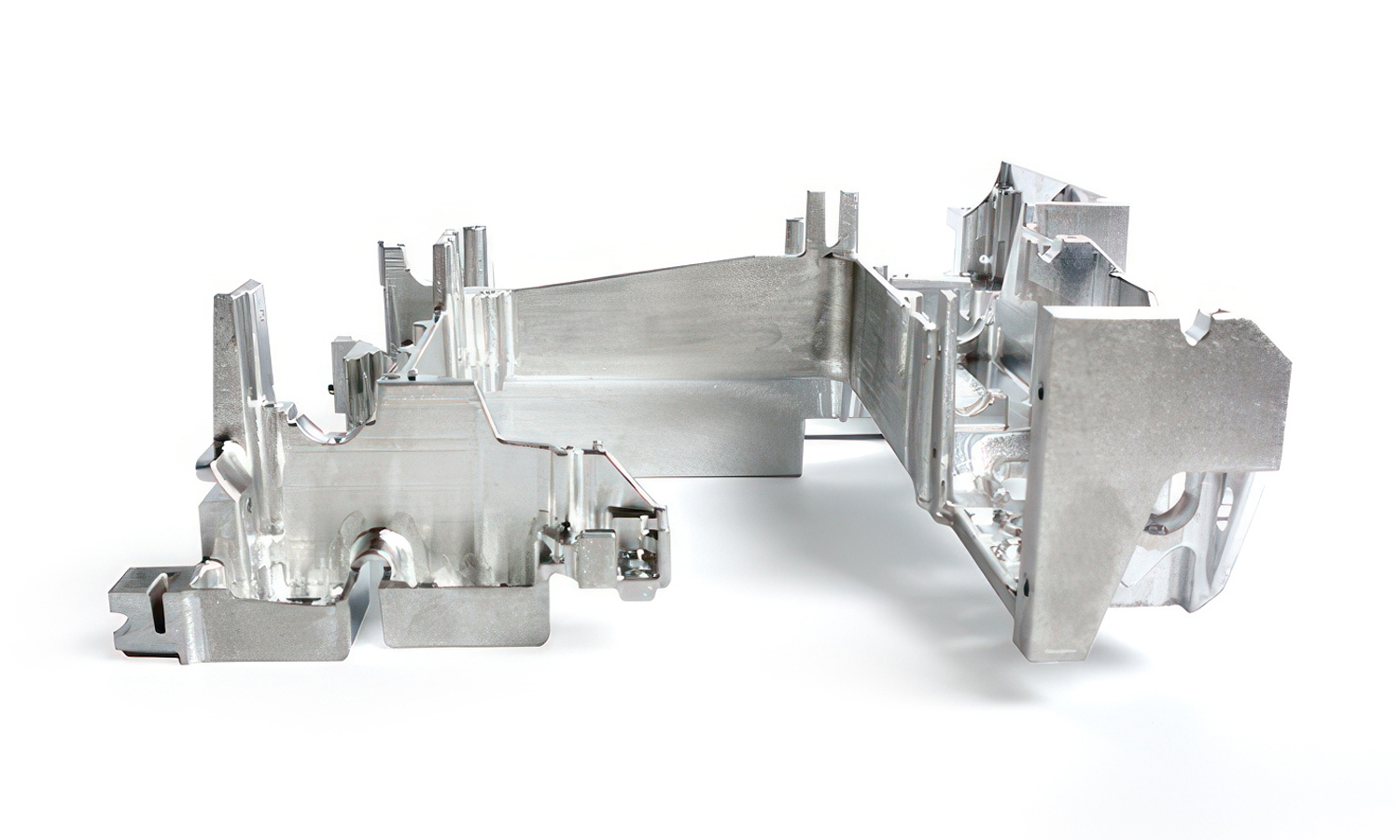

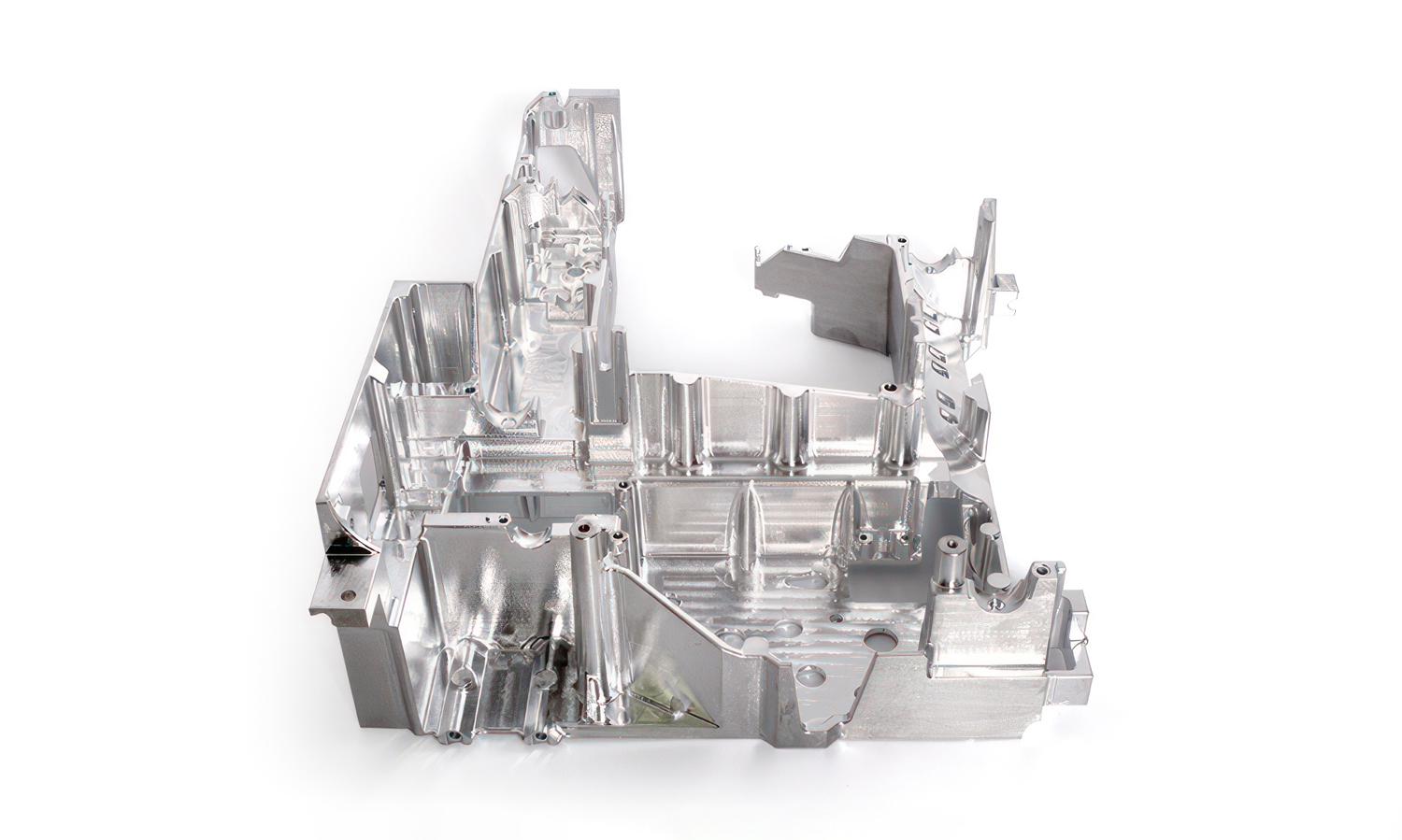

This part is milled from a high-grade aluminum alloy, offering excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. The chassis features a complex multi-level structure, numerous through-holes, recessed pockets, and tight-tolerance mounting points-all machined to exacting standards. Such a component likely serves as a foundational structural element or enclosure, supporting critical modules or subsystems while maintaining precise alignment and stability.

What stands out is the exceptional surface finish and dimensional accuracy, which could only be achieved through advanced 3-, 4-, or even 5-axis CNC machining. Each contour, bore, and slot reflects meticulous planning and programming, with material removed strategically to balance rigidity and weight savings. Internal ribbing and bracket-like features suggest this part may bear significant load or interface with other precision assemblies.

If you’re seeking similarly complex aluminum components-whether for prototyping or production-FacFox offers industry-leading CNC machining services. Equipped with state-of-the-art milling centers and a team of skilled engineers, FacFox delivers tight-tolerance parts with consistent quality and fast lead times. Whether your design calls for aerospace-grade materials, custom surface finishes, or mass customization, FacFox is your reliable partner in precision manufacturing.

Solution

- Step 1: Material Selection and Preparation. A high-strength aluminum alloy block was selected based on the design’s mechanical and thermal requirements. The raw material was cut to rough dimensions using a bandsaw and then cleaned to remove surface contaminants.

- Step 2: Workholding Setup. The aluminum block was mounted onto the CNC milling machine using custom-designed fixtures and vises. The setup was verified to ensure stability during high-speed operations.

- Step 3: Rough Machining. Excess material was removed using high-speed roughing tools. The major contours, cutouts, and internal cavities were machined with large end mills to establish the basic geometry of the chassis.

- Step 4: Semi-Finishing Passes. Smaller tools were used to perform semi-finishing passes. This step brought the part closer to final dimensions while maintaining a small allowance for the finishing stage. Intermediate features such as slots, bosses, and threaded holes were machined.

- Step 5: High-Precision Finishing. High-precision tools and fine feeds were used to achieve tight tolerances and smooth surface finishes. All critical dimensions, mounting surfaces, and interfaces were machined during this stage.

- Step 6: Multi-Axis Machining. The part was repositioned for 4-axis or 5-axis machining to reach undercuts, angled features, and internal structures. Complex geometry, such as ribbing and thin walls, was carefully milled to avoid deformation.

- Step 7: Deburring and Edge Finishing. Sharp edges and burrs were removed manually and via automated deburring tools. This improved both safety and assembly fit.

- Step 8: Quality Inspection. Dimensional accuracy was verified using CMM (Coordinate Measuring Machine) and calipers. Surface roughness and flatness were also checked to meet design specifications.

- Step 9: Surface Treatment (Optional). If required, the part was anodized or bead-blasted to enhance corrosion resistance and appearance.

- Step 10: Final Cleaning and Packaging. The completed chassis was ultrasonically cleaned, dried, and packed in protective materials to prevent damage during shipping.