- CNC Machined Jacquard Flat Sock Circular Knitting Machine Part

- SLA 3D Printed Car Headlight Assembly Resin Prototype

Material Resin

Quantity 2 pcs

Price Range $1-100

Lead Time 4 workdays

Gallery

About Project

In the world of smart devices and precision electronics, light diffusion plays a key role in delivering clean, uniform LED signals. Recently, we developed a set of sensor LED light diffuser prototypes using SLA 3D printing, tailored for optical clarity and precise light guidance in compact electronic assemblies.

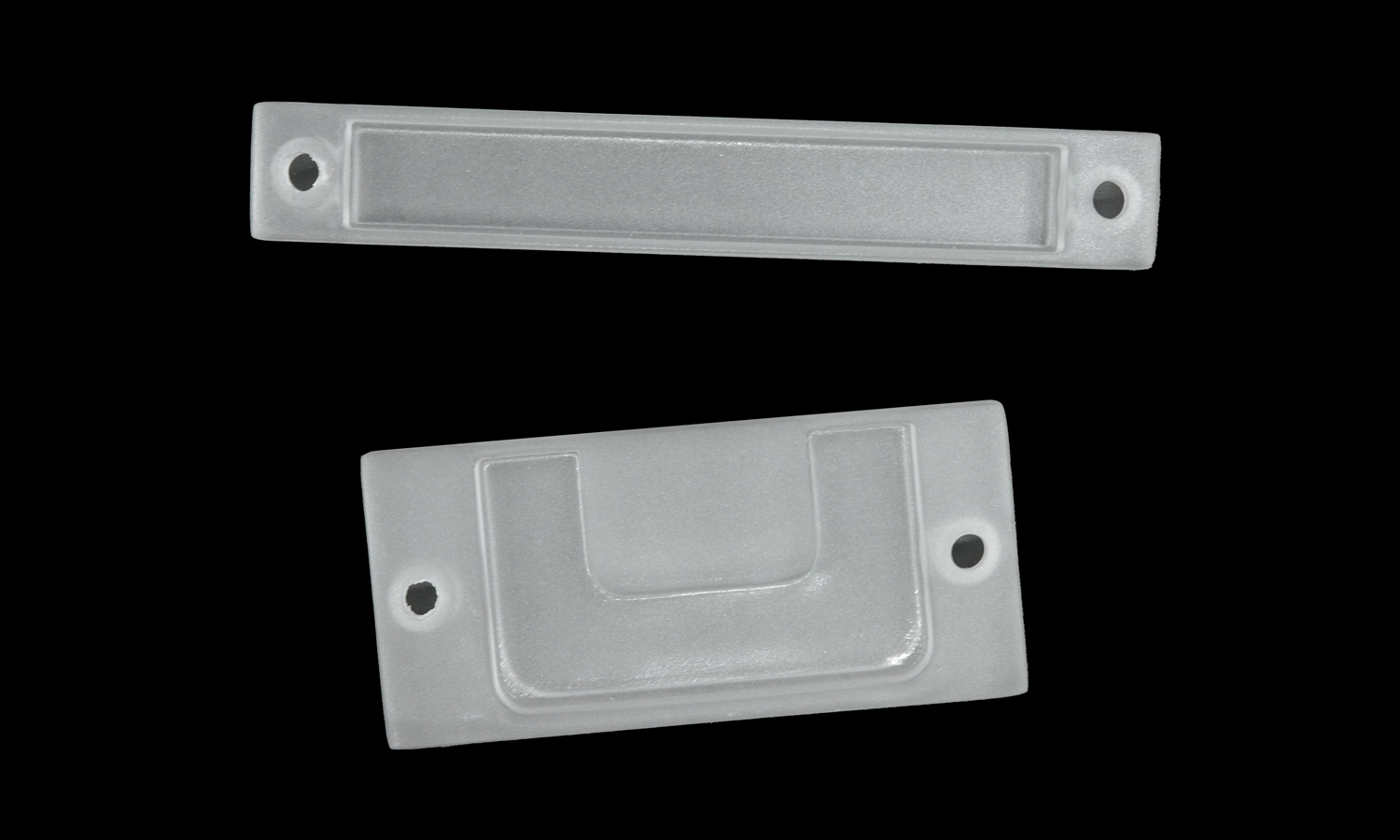

These diffuser prototypes feature sleek, functional designs-long rectangular and compact U-shaped geometries with mounting holes for easy integration. Originally printed with SLA Frosted Clear Resin, the raw parts exhibited a translucent but irregularly frosted appearance, characteristic of the resin’s high detail and resolution. While this finish is excellent for basic validation, high-performance optical parts require greater surface refinement.

To achieve the final look and function, the prototypes went through a meticulous post-processing workflow. First, they were polished to remove print lines and smooth out the surface. A thin transparent spray coating was applied to achieve crystal clarity, transforming the parts into nearly glass-like components. Finally, the parts were sand-blasted, restoring a uniform frosted texture that evenly diffuses light-ideal for sensor indicators and ambient lighting applications.

The result is a highly functional and aesthetically refined part that demonstrates not only the power of SLA printing but also the importance of post-processing in achieving application-ready prototypes. These light guides can be mounted directly over LEDs to channel light precisely, while their frosted finish eliminates harsh glare and hotspots.

At FacFox, we specialize in high-resolution SLA 3D printing and tailored post-processing to help engineers and designers bring optical components to life. Whether you need early-stage prototypes or small-batch production, our expertise in materials like SLA Frosted Clear Resin and finishing techniques ensures your parts look and perform exactly as needed. Reach out to FacFox to get started on your next precision prototyping project.

Solution

- Step 1: The diffuser prototypes were designed with precise geometries to fit over LED indicators and sensor components. Mounting holes and light-guiding channels were integrated into the CAD models to ensure functional accuracy.

- Step 2: The models were printed using SLA Frosted Clear Resin, a material known for its fine resolution and semi-translucent properties. The prints were produced on a high-resolution SLA 3D printer to capture all intricate details of the design.

- Step 3: After printing, the parts were cleaned and cured under UV light to ensure complete polymerization of the resin and to stabilize the material for further processing.

- Step 4: The cured parts were polished manually, and fine abrasives were used to remove surface irregularities and enhance transparency, preparing them for the next finishing step.

- Step 5: A thin layer of transparent coating was sprayed onto the polished parts to give them a crystal-clear finish. This coating also helped to seal the surface and minimize micro-imperfections.

- Step 6: The clear-coated parts were then sand-blasted to restore a consistent frosted appearance. This step was applied uniformly to eliminate uneven texture and provide a smooth, light-diffusing finish suitable for LED lighting applications.

- Step 7: The final parts were inspected for clarity, uniformity, and dimensional accuracy before being approved for functional testing or integration into prototype assemblies.