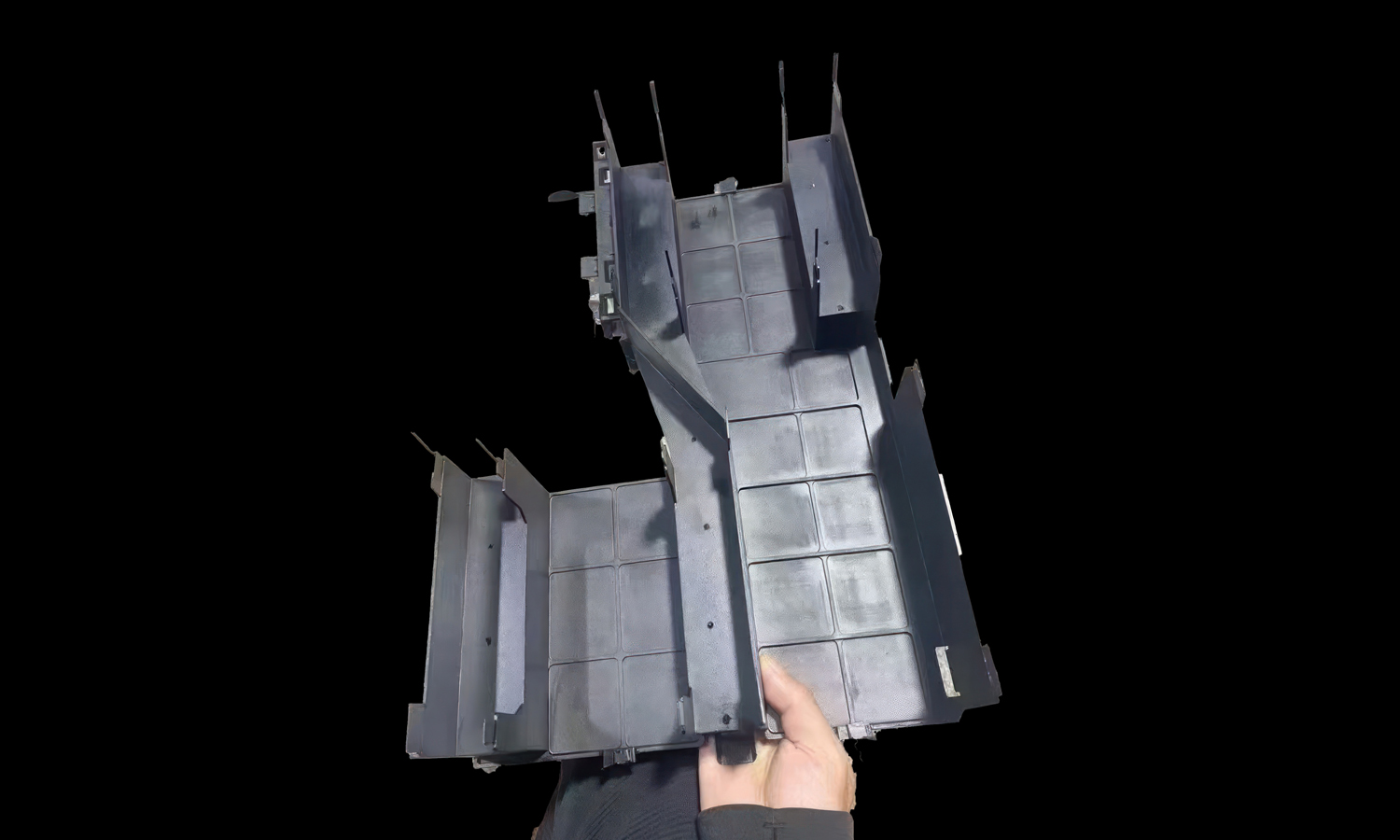

- SLA 3D Printed Heavy-duty Mechanical Unit Sectional Model

- SLA 3D Printed Gastrointestinal Tract Anatomical Model

Material Plastic, Resin, Rubber

Quantity 30 pcs

Price Range $100-1,000

Lead Time 5 workdays

Gallery

About Project

Here’s a look at one of our urethane casting projects – a rigid housing tray with reinforcement ribs and multiple mounting features. Parts like these are commonly used in automotive interiors and electronic assemblies, where strength, dimensional accuracy, and durability are essential.

Using ABS-like polyurethane resin, the casting replicates the master model with excellent precision. The result is a lightweight, impact-resistant component with a professional surface finish, closely mimicking injection-molded plastics.

Why choose urethane casting?

- Ideal for low-volume production without investing in steel tooling

- Produces functional prototypes that perform like end-use ABS or PP parts

- Supports a wide range of colors, textures, and mechanical properties

- Delivers fast turnaround for testing and pilot runs

At FacFox, we help clients bridge the gap between concept and mass production. Whether it’s an automotive housing, an electronics enclosure, or a custom mechanical component, our urethane casting service ensures reliable results with speed and precision.

¤æē Turn your designs into functional reality with FacFox’s urethane casting service – your partner in high-quality, small-batch manufacturing.

Solution

- Step 1: DFM Review. The CAD data were received and reviewed for draft, wall thickness, ribs, and undercuts. Parting lines, gates, and vents were defined.

- Step 2: Master Fabrication. A master model was produced (SLA/CNC), post-cured, and finished; surfaces were sanded to a uniform matte so the texture could be transferred to the mold.

- Step 3: Mold Box Setup. The master was located on a base, datum pins were added, and a leak-free mold frame was assembled. Release agent was applied to all relevant surfaces.

- Step 4: Silicone Mixing & Degassing. RTV silicone rubber was weighed, mixed, and vacuum-degassed to remove entrapped air.

- Step 5: Silicone Pouring. Silicone was poured from height in a thin stream to minimize bubbles and fully encapsulate the master, cores, and indexing features.

- Step 6: Mold Cure & Master Removal. The silicone was cured to full hardness. The mold was opened along the planned parting line and the master was removed cleanly.

- Step 7: Mold Conditioning. The silicone mold was baked/conditioned to drive off volatiles, then treated with a compatible release agent. Inserts and temporary cores were prepared.

- Step 8: Resin Preparation. ABS-like polyurethane resin was selected. Components A/B were pre-warmed, accurately weighed, pigmented to black, and vacuum-degassed.

- Step 9: Mold Preheat & Assembly. The mold was preheated for dimensional stability. Metal pins, brass inserts, and any bosses were placed, and the mold halves were clamped.

- Step 10: Casting. Resin was poured through the sprue (under vacuum assist), and the filled mold was placed in a pressure pot to collapse residual micro-bubbles.

- Step 11: Cure & Post-Cure. The casting was cured in-mold, then post-cured in an oven to reach final mechanical properties.

- Step 12: Demold & Deflash. The part was demolded. Gates, runners, and flash were trimmed; edges were deburred and sharp corners were broken.

- Step 13: Secondary Machining. Critical holes were drilled/reamed, slots were cleaned, and mounting features were verified. Threads and inserts were installed where required.

- Step 14: Surface Finishing. A light bead-blast/matte finish was applied to match the master; optional coating was sprayed for color uniformity and wear resistance.

- Step 15: Quality Inspection. Dimensions were inspected with calipers/CMM against the CAD. Flatness, wall thickness, and clip locations were checked; a fit-test with mating parts was performed.

- Step 16: Packaging & Mold Storage. The part was cleaned, labeled, and packed with protective foam. The silicone mold was cataloged and stored for repeat casting runs.