SLA 3D Printed Vehicle Frame with Durable Resin

Posted on 2020-10-21 in Automotive ôñ ÌݧҧÎ

Gallery

About Project

A vehicle frame, also known as its chassis, is the main supporting structure of a motor vehicle to which all other components are attached, comparable to the skeleton of an organism.

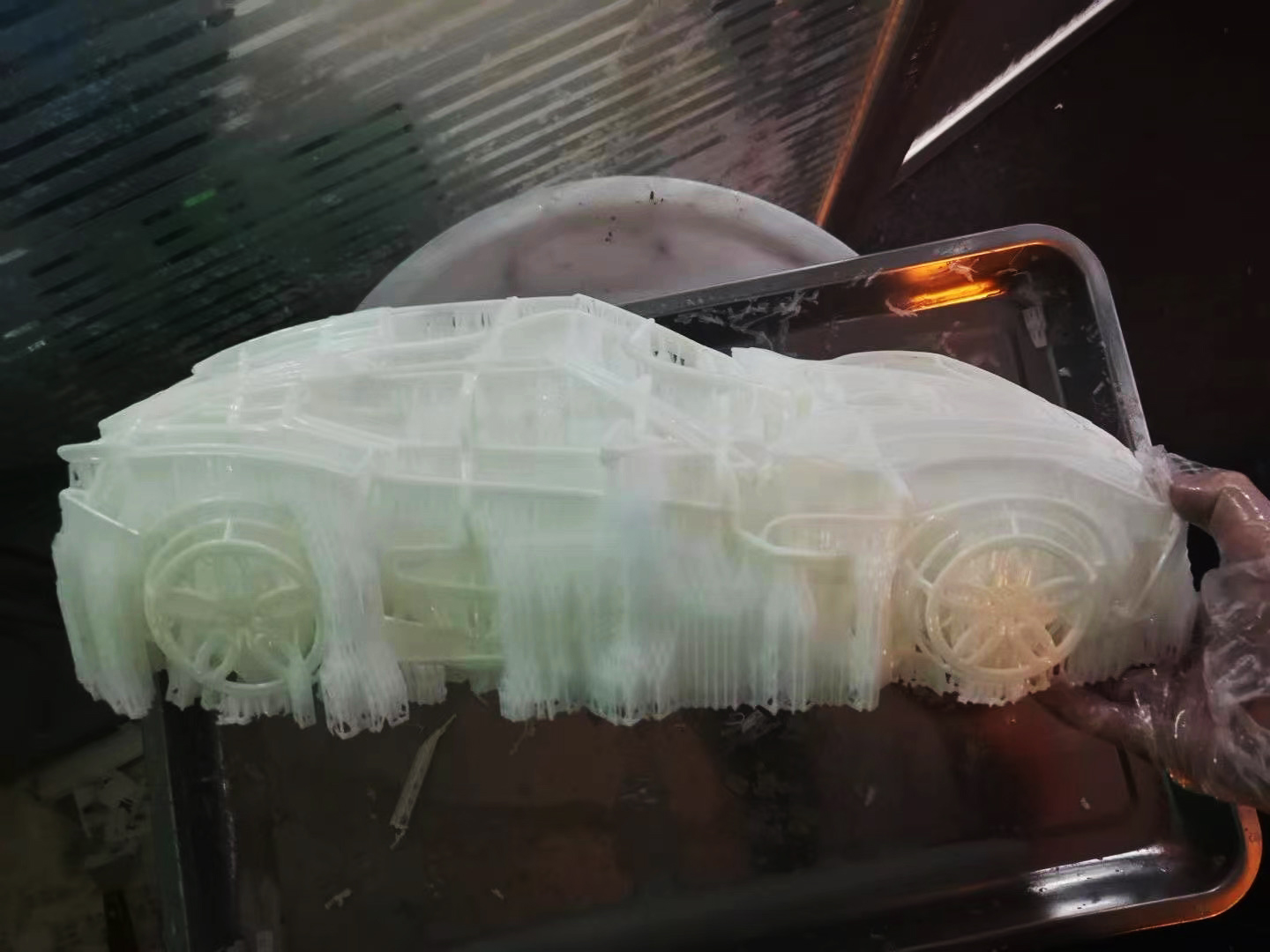

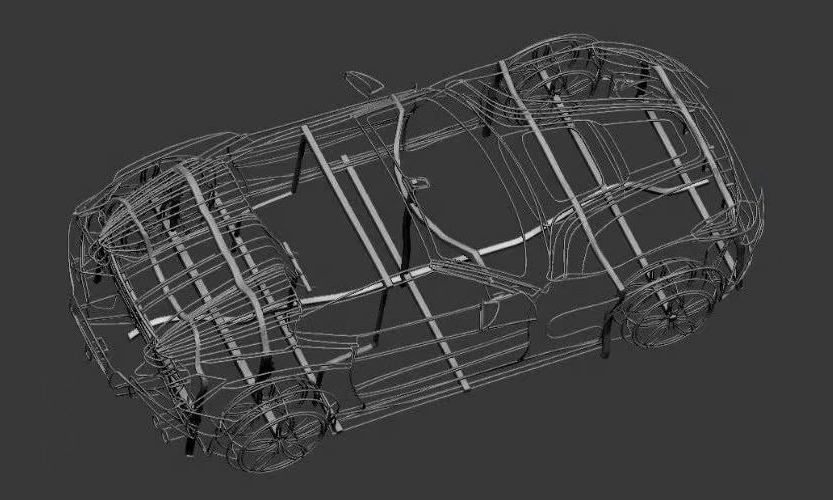

Indeed the frame we printed is not strictly a vehicle frame, but more like a 3D sketch of a car.

Although the vehicle frame model is composed of only thin lines, the material it consumes is not less than a complete model as it needs so many supports. The hollowed wheels are a bit challenging for post-processing.

Solution

- Step 1: Check the model in advance, especially the overhang structure, in case it breaks or transforms during printing. Add supports to the model and export the STL file into the SLA 3D printer. Each SLA printer includes software to specify printing settings and slice the digital model into layers for printing. Once setup is complete, the print preparation software sends the instructions to the printer via a wireless or cable connection.

- Step 2: After a quick confirmation of the correct setup, the printing process begins and the machine can run unattended until the print is complete. In printers with a cartridge system, the material is automatically refilled by the machine.

- Step 3: Once the printing is completed, parts require rinsing in isopropyl alcohol (IPA) to remove any uncured resin from their surface. After rinsed parts dry, some materials require post-curing, a process that helps parts to reach their highest possible strength and stability. Finally, remove supports from the parts and sand the remaining support marks for a clean finish. SLA parts can be easily machined, primed, painted, and assembled for specific applications or finishes.