- CNC Machined Aluminum Alloy Chassis Complex Geometry

- CNC Machining Al6061 Compound Miter Saw Base Assembly Part

Material Plastic, Metal

Quantity 1 pcs

Price Range $1-100

Lead Time 6 workdays

Gallery

About Project

At FacFox, we’re passionate about bringing innovative designs to life with unparalleled precision and quality. We recently partnered with a client in the automotive industry to produce a custom motorcycle taillight component that truly showcases the power of 3D printing and CNC machining working in harmony.

This advanced taillight assembly features a robust design comprising three key components:

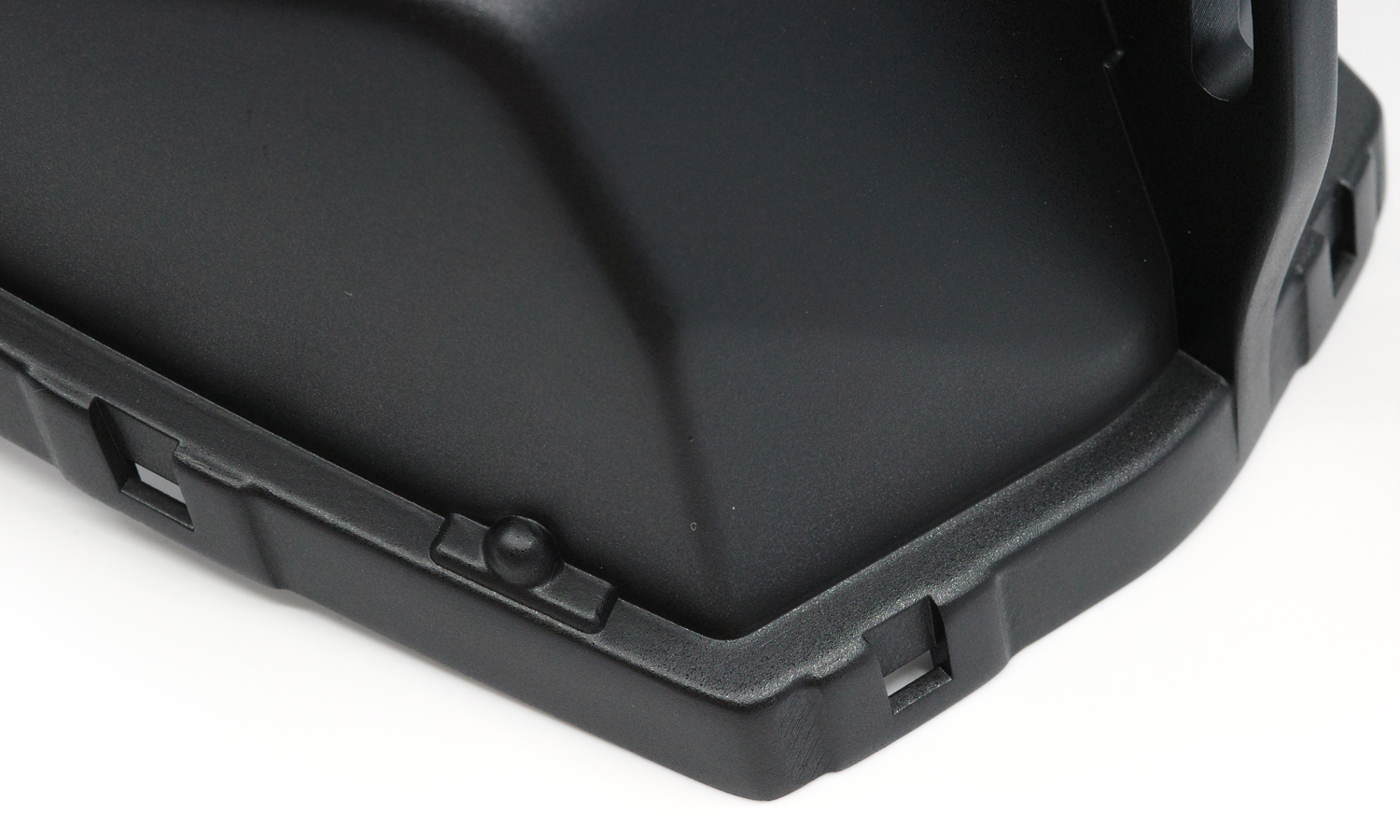

- Two 3D Printed Resin Shells (Painted Black): These form the outer casing of the taillight. Utilizing advanced resin 3D printing technology, we were able to create complex geometries with smooth finishes. After printing, the shells were meticulously painted black to achieve a sleek, OEM-quality appearance, ready for seamless integration into the motorcycle’s design.

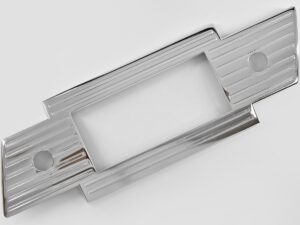

- One CNC Aluminum Heat Dissipation Component: Housed within the shells, this crucial part is precision-machined from aluminum using our state-of-the-art CNC capabilities. Its primary function is to efficiently dissipate heat generated by the taillight’s internal electronics, ensuring optimal performance and longevity. The intricate finned design is a testament to the precision achievable with CNC machining.

Precision is Paramount, and We Deliver.

For automotive components like this taillight, accuracy in manufacturing is not just a preference, it’s a necessity. The assembly of these three distinct parts, with their varying materials and manufacturing processes, demanded exceptionally tight tolerances. Our expertise in both 3D printing and CNC machining, coupled with rigorous quality control, ensured that each component fit together perfectly, leading to a flawless final product.

We are proud to be a reliable, long-term collaborator for this client, consistently meeting their high standards for precision and quality. This project is a prime example of how FacFox can support the automotive industry in developing and producing custom, high-performance parts.

Why Choose FacFox for Your Automotive Manufacturing Needs?

Whether you’re prototyping a new design or producing end-use parts, FacFox offers a comprehensive suite of manufacturing services tailored for the automotive sector. From rapid prototyping with 3D printing to high-precision CNC machining for critical components, we provide:

- Expertise in Diverse Manufacturing Technologies: Leverage our proficiency in 3D printing (SLA, FDM, SLS, MJF, etc.) and CNC machining for a wide range of materials.

- Unwavering Commitment to Precision: We understand the stringent requirements of the automotive industry and deliver parts with exceptional accuracy.

- Reliable Partnership: We aim to be more than just a supplier; we strive to be a trusted, long-term manufacturing partner.

- Scalable Production: From one-off prototypes to low-volume production runs, we can accommodate your needs.

Ready to bring your next automotive innovation to life? Contact FacFox today to discuss your project and discover how our advanced manufacturing capabilities can accelerate your success.

Solution

- Step 1: Resin Shells were 3D Printed. The two outer shells of the taillight were produced using an advanced resin 3D printing process. The CAD models were prepared and sliced, and the resin material was cured layer by layer by a UV light source until the complete geometry of each shell was formed.

- Step 2: Resin Shells were Cured and Cleaned. After printing, the resin shells were subjected to a post-curing process to fully solidify the material and enhance their mechanical properties. Subsequently, any excess resin was meticulously cleaned from the surfaces of both shells.

- Step 3: Resin Shells were Painted Black. Once cured and cleaned, the 3D printed resin shells were prepped for finishing. A durable black paint was then applied to their exterior surfaces, ensuring a smooth, uniform, and aesthetically pleasing finish that met the client’s specifications.

- Step 4: Aluminum Heat Dissipation Component was CNC Machined. Concurrently, the aluminum heat dissipation component was manufactured using CNC (Computer Numerical Control) machining. A block of aluminum was secured in the CNC machine, and precise cutting tools, guided by the digital design, removed material to create the intricate finned structure of the heat sink.

- Step 5: CNC Component was Deburred and Finished. Following the CNC machining process, the aluminum heat dissipation component was carefully deburred to remove any sharp edges or burrs left by the cutting tools. It was then cleaned and, if necessary, subjected to additional finishing processes to achieve the desired surface quality.

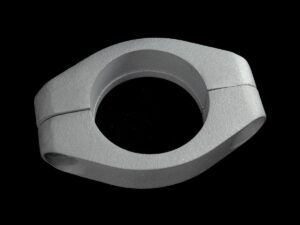

- Step 6: Components were Assembled. Finally, all three completed components – the two black-painted 3D printed resin shells and the CNC-machined aluminum heat dissipation component – were precisely assembled. Due to the high precision achieved in each manufacturing step, the parts fit together seamlessly, forming the complete custom motorcycle taillight.