- SLA 3D Printed Resin Abstract Resin Geometry Sculpture

- SLA 3D Printed Golden 2026 Commemorative Sphere

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

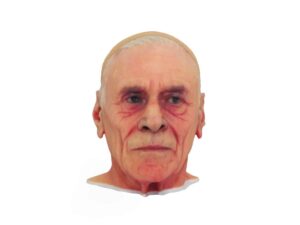

Abstract art is about finding the soul of a form through simplification, and this latest resin 3D print does exactly that. This stylized female figure translates human grace into a language of sharp planes and rhythmic facets, drawing inspiration from the bold experiments of Cubism and Modernism.

The result? A striking silhouette that plays beautifully with light and shadow.

Precision in Every Facet

To capture the crisp, knife-like edges of this geometric design, we utilized high-resolution resin printing. This process ensures:

- Matte, Uniform Finish: A smooth surface that highlights the sculpture’s angular rhythm without distracting layer lines.

- Intricate Details: The elongated proportions and featureless, tilted head maintain their anonymous, sculptural power.

- Structural Integrity: Even with delicate, slim legs, the figure remains balanced on its minimalist plinth.

While resin printing often requires internal drainage or support points-visible here as small, professional mends on the calves-these are a testament to the authentic 3D fabrication process, ensuring the model remains hollow, lightweight, and crack-resistant.

Bring Your Vision to Life with FacFox

Do you have a complex digital sculpture or a geometric prototype that needs to jump off the screen? At FacFox, we specialize in turning high-concept designs into physical reality.

Whether you need the ultra-fine detail of SLA/DLP resin printing, the durability of SLS nylon, or industrial-grade metal prints, our team provides professional post-processing to ensure your work looks gallery-ready.

Why choose FacFox?

- Expert Finishing: From sanding to custom coatings, we handle the details.

- Global Shipping: Fast turnaround, no matter where your studio is located.

- Material Variety: Over 100+ materials to suit any aesthetic or functional need.

Ready to start your next project? Upload your STL file to FacFox today and let’s create something extraordinary together.

Solution

- Step 1: The 3D model of the faceted figure and rectangular base was prepared, and the sculpture was oriented to minimize visible support contact on the most prominent planes.

- Step 2: Drainage and venting openings were added in the legs and the base underside as needed, and support structures were generated with emphasis on placing contact points on less visible areas.

- Step 3: The resin printer was set up, the build plate was leveled, and the resin vat was filled with the selected resin.

- Step 4: The sculpture was printed layer by layer, and the build was completed with the figure and base attached to the support network.

- Step 5: The printed part was removed from the build plate, and excess liquid resin was drained off the surface and from internal cavities.

- Step 6: The part was washed in cleaning solvent (such as IPA) to remove uncured resin, and the openings were flushed to clear trapped residue.

- Step 7: The part was air-dried, and remaining solvent was allowed to evaporate fully before curing.

- Step 8: The print was UV-cured to reach final material strength, and curing was performed evenly to reduce warping on the thin legs and sharp facets.

- Step 9: Support structures were clipped away, and support contact points were trimmed to avoid chipping on edges and corners.

- Step 10: The leg openings and the underside base opening were patched, and the three holes were filled using resin, putty, or a compatible filler before being cured or set.

- Step 11: The repaired areas were sanded flush, and the surrounding surfaces were blended to reduce visibility of the patches, especially on the calves.

- Step 12: The entire surface was sanded progressively to achieve a consistent matte finish, and sharp facets were preserved by controlled hand-sanding.

- Step 13: Surface defects were spot-filled as needed, and additional sanding was performed until the finish appeared uniform.