Lost-wax Cast Abstract Metal Sculpture

Posted on 2020-04-22 in Art ┬Ę Ķē║µ£»

Process Metal Casting, Polish

Material Metal, Other

Quantity 1 pcs

Price Range $100-1,000

Lead Time 5 workdays

Material Metal, Other

Quantity 1 pcs

Price Range $100-1,000

Lead Time 5 workdays

Gallery

About Project

Each city has its own heartbeat that the inhabitants enjoyed. It's not one specific people, trend, or designer that defines a city's styleŌĆöbut all of us. Each city has its own spirit, attitude, and approach to fashion. The sculptures on the street also participate in the style creation.

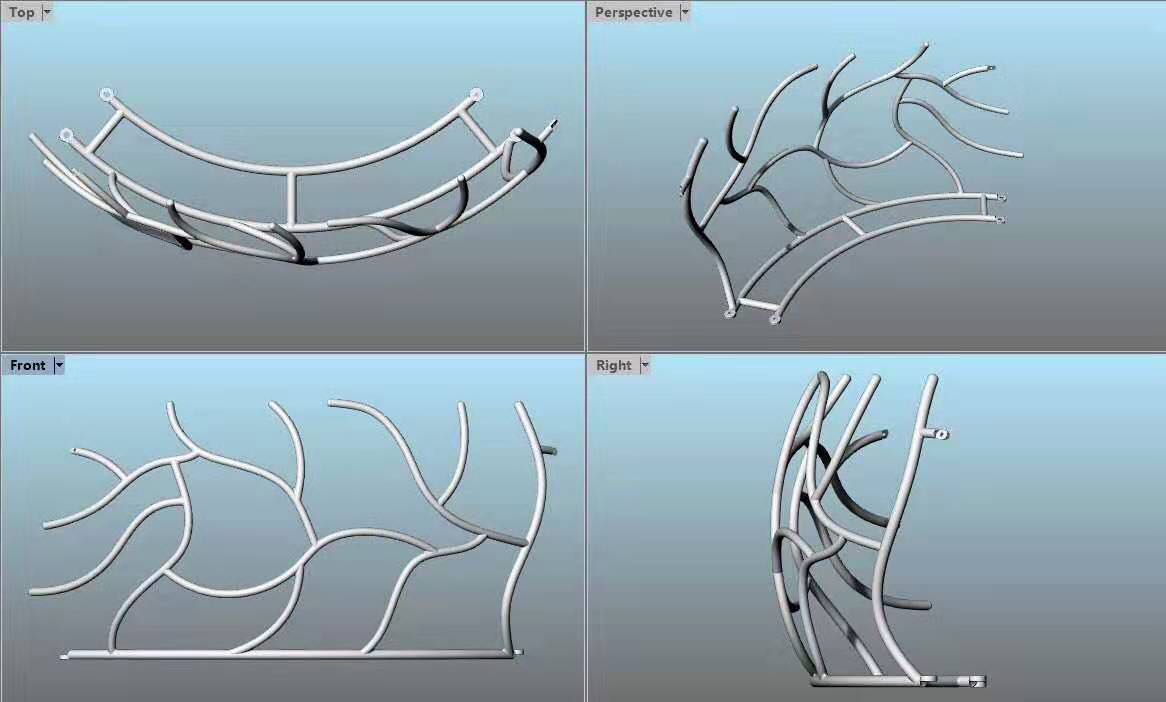

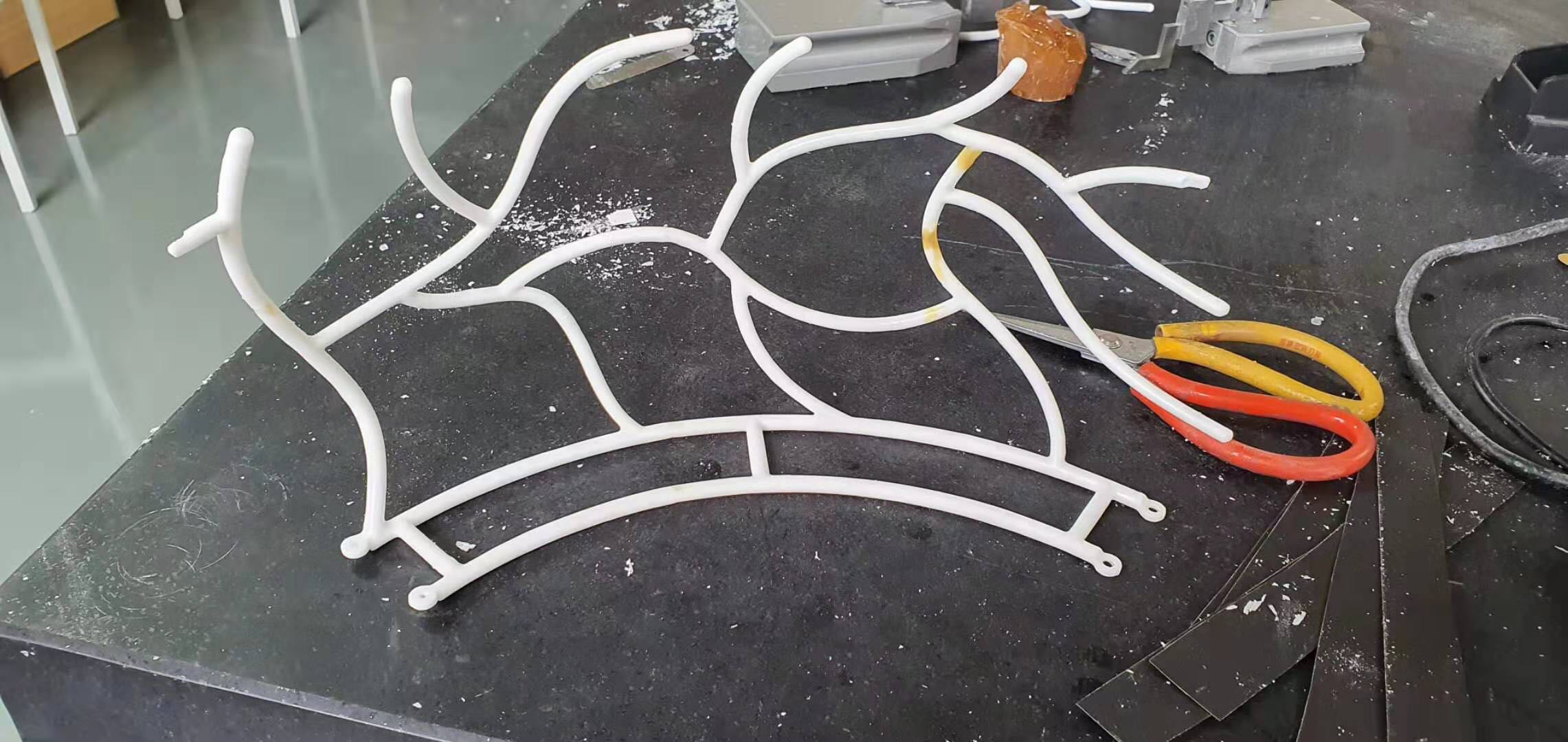

This bronze sculpture is inspired by the branch and vine of plants. Our customer once hesitated between CNC machining, 3D printing, and metal casting, but decided to choose the lost-wax casting method under our suggestion.

Lost-wax investment method is excellent in accuracy and cost reduction, also allow the freedom in design to some extent.

Solution

- Step 1: Inject the molten wax into the pattern mold and wait for its cooling and hardening into a wax pattern.

- Step 2: Assemble the wax pattern onto a “wax pattern tree” with a wax sprue (a gate to pour the liquid metal material in).

- Step 3: Repeatedly submerge the tree into a ceramic slurry and sand alternately to form a rigid and thick outer shell. When the ceramic shell drys out, the whole part becomes an investment mold.

- Step 4: Heat the investment mold rapidly so that the wax can melt and drain quickly to minimize the inner stress and make space for the wax expansion.

- Step 5: Heat the investment mold to remove moisture and residual wax, then pour the material into the mold by gravity or air pressure.

- Step 6: Remove the investment shell from the casting part by hammering, basting or other methods.

- Step 7: Saw off the casting part from the tree and conduct finish process.