Gallery

About Project

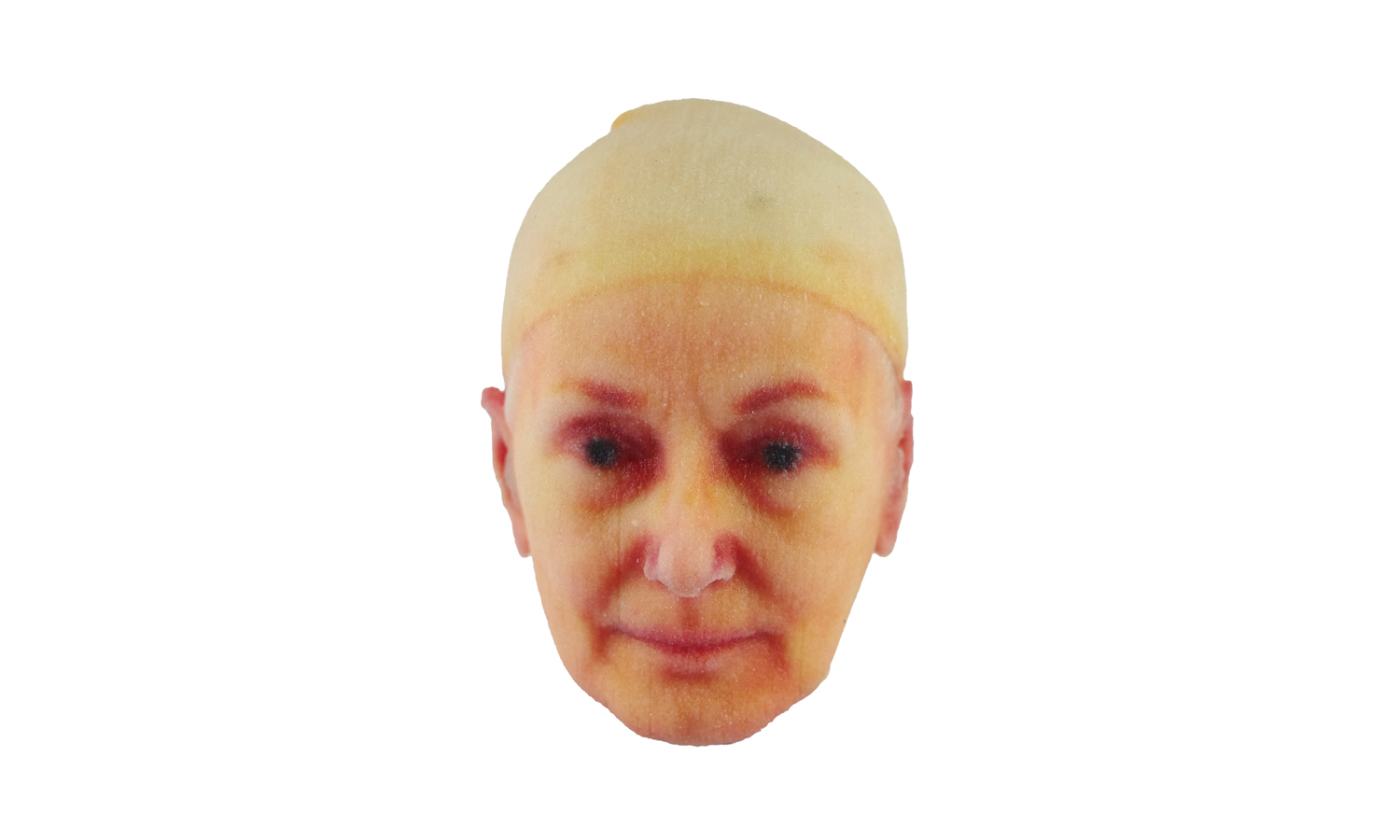

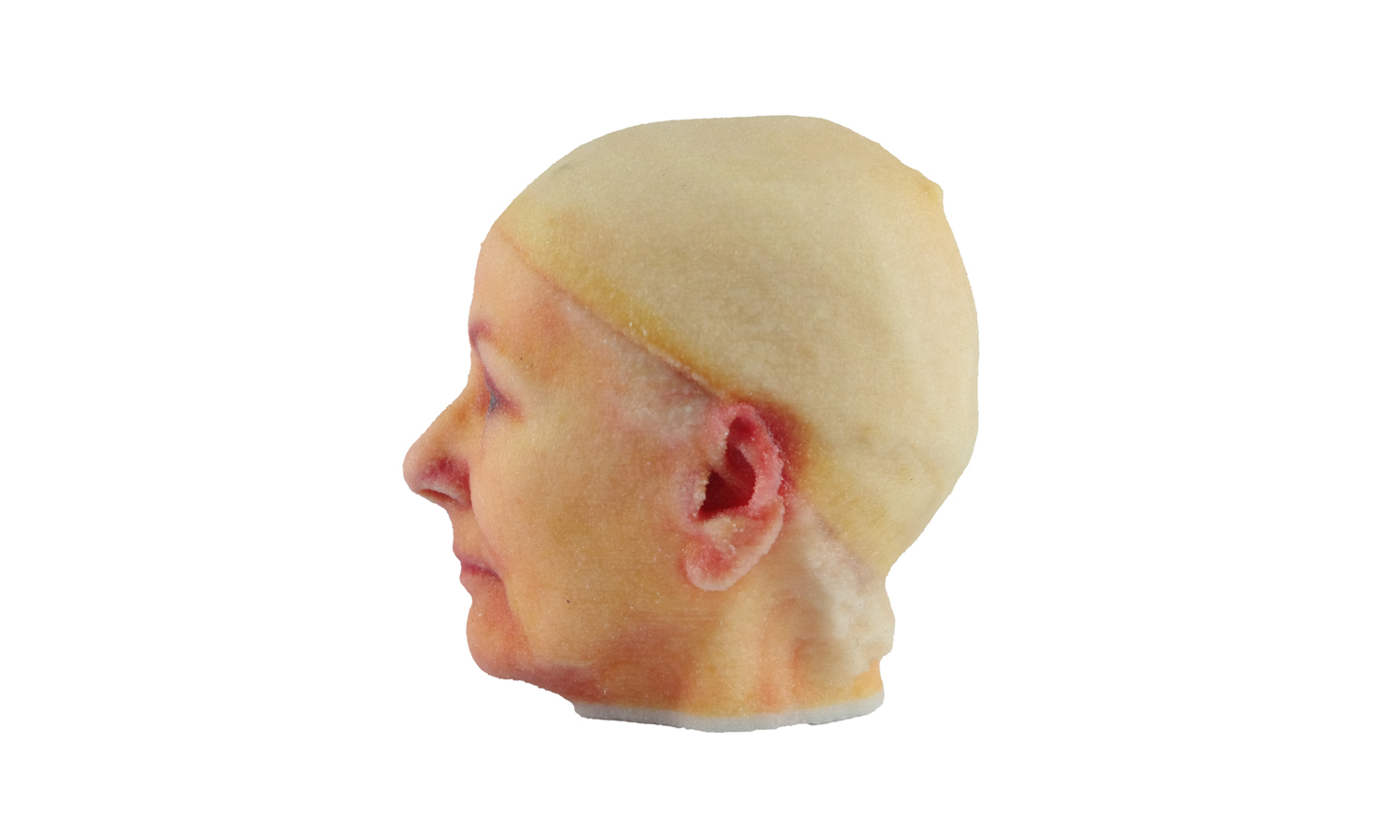

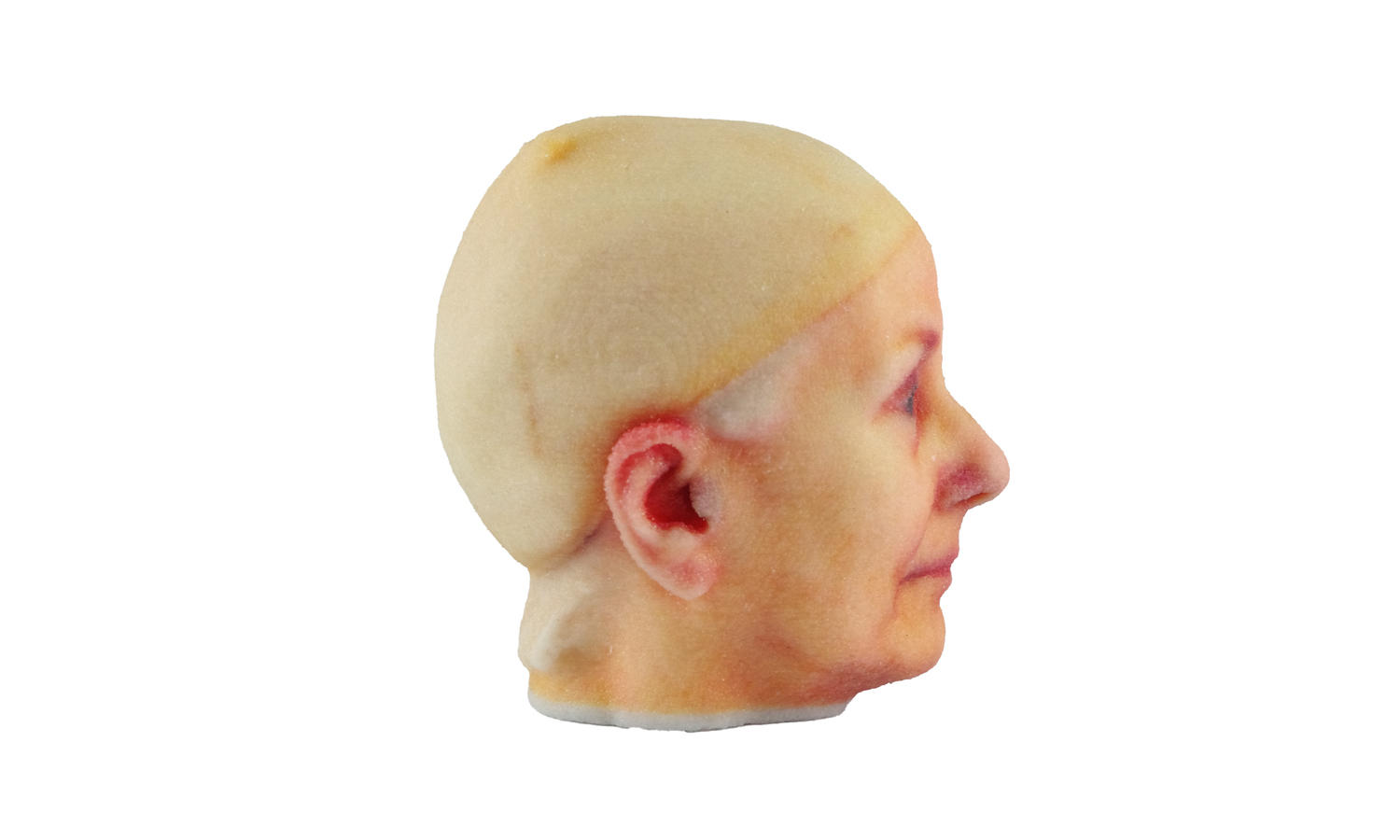

Behold this intriguing miniature head sculpture of an elder woman, brought to life through ColorJet 3D printing technology. The full-color capability of this process aims to capture the nuances of skin tone and facial features, offering a unique representation in three dimensions.

While the vibrancy of the colors is certainly a standout characteristic – boasting perhaps the highest saturation among full-color 3D printing methods – closer inspection reveals some interesting trade-offs. The skin tone, for instance, appears to lean quite heavily into the red spectrum. Details in the facial features, such as the finer lines of the face, the intricacies of the eyes, and the texture of the hair, seem somewhat softened and lack sharp definition. Additionally, the surface exhibits noticeable vertical striations, indicating the layer-by-layer build process inherent in many 3D printing techniques.

Despite these observations, it’s important to acknowledge that ColorJet 3D printing often stands out as the most economically accessible full-color 3D printing solution available today. This makes it a compelling option for projects where budget is a primary concern and a high degree of color saturation is desired, even if it comes with some compromise in fine detail and color accuracy.

Looking to bring your own colorful visions to life? FacFox’s ColorJet 3D printing service offers an affordable entry point into the world of full-color prototypes, models, and artistic creations. Explore the possibilities and discover how this technology can help you realize your designs in vibrant hues.

Solution

- Step 1: A digital 3D model of the elder woman’s head was created using computer-aided design (CAD) software.

- Step 2: The 3D model was then prepared for printing by slicing it into numerous thin cross-sectional layers.

- Step 3: A fine powder material, typically a gypsum-based powder, was spread in a thin layer across the build platform of the ColorJet 3D printer.

- Step 4: Colorant and binder solutions were selectively jetted onto the powder bed according to the digital model’s cross-sectional data. The colorant was deposited to achieve the desired hues for each point, and the binder was applied to solidify the powder particles in the shape of the object.

- Step 5: After one layer was completed, another thin layer of powder was spread, and the process of jetting colorant and binder was repeated. This layer-by-layer process was continued until the entire 3D object was formed within the powder bed.

- Step 6: Once the printing was finished, the build platform was removed from the printer, and the unbound powder was carefully removed to reveal the 3D printed head sculpture.

- Step 7: Excess powder was gently brushed and blown away from the surface of the printed part.