- SLA 3D Printed Apple Liquid Glass Hello Ornament

- Transforming Spaces with Large-Format PETG 3D Printing

Material Plastic

Quantity 1 pcs

Price Range $100-1,000

Lead Time 3 workdays

Gallery

About Project

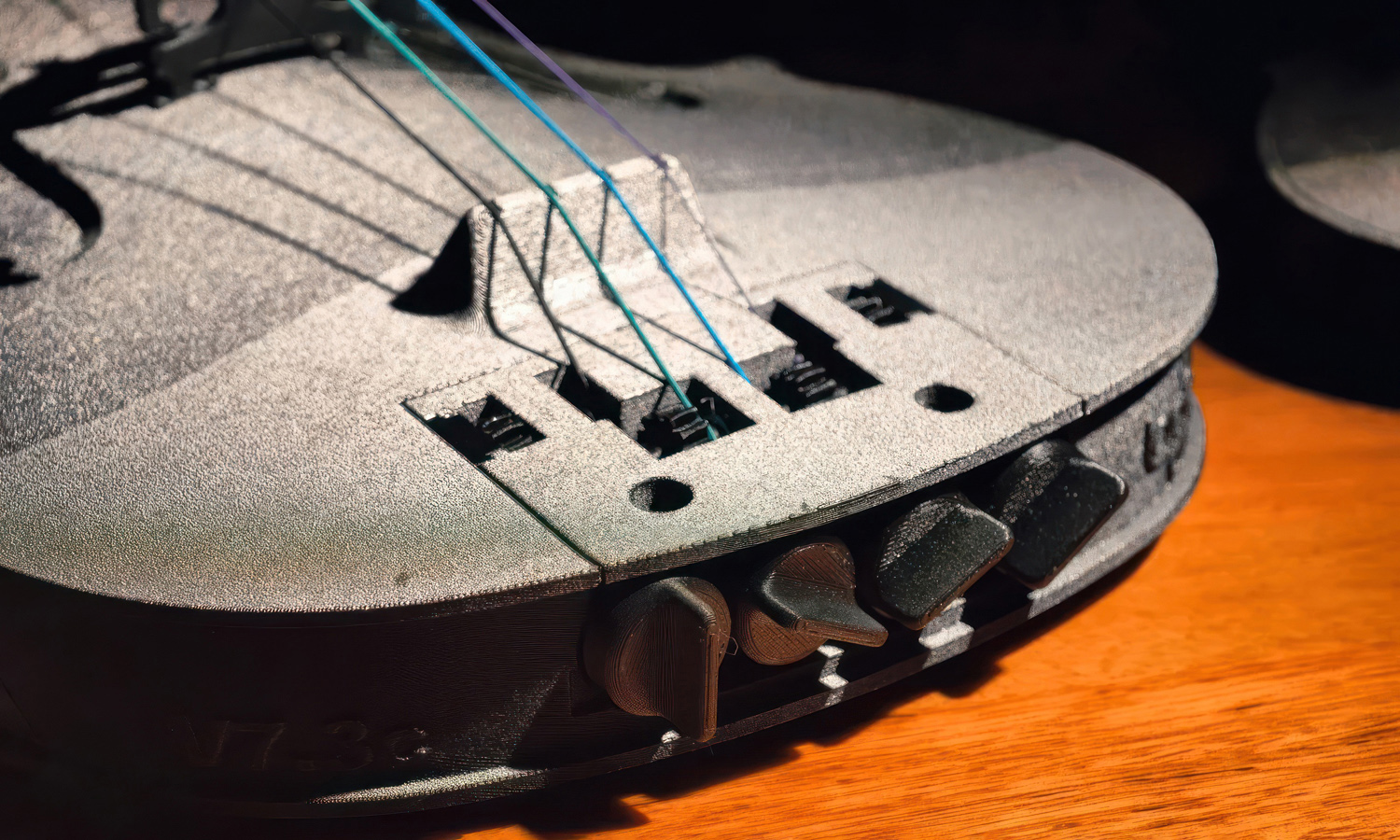

Have you ever imagined playing music on a violin made entirely with 3D printing? Maker @nenipresotreta recently tried exactly that, printing a 1/4 size functional violin downloaded from MakerWorld.

Printing & Materials

The build required around 1 kg of filament and took nearly 40 hours to complete. PETG GF (glass fiber reinforced PETG) was chosen for the print, offering toughness and stability. While it produced a surprisingly decent sound, acoustically it fell short of wood. With a lower Young’s modulus than spruce or maple, the printed body was softer yet denser, which led to sustain issues. The tone was warmer but lacked the bright resonance typical of traditional violins.

Interestingly, materials with higher stiffness such as PLA CF (carbon fiber reinforced PLA) might perform better, since their modulus is closer to natural tonewoods. Still, wood’s unique advantage lies in its high specific stiffness-being both lightweight and rigid-which explains why aged spruce and maple remain the gold standard for violin making.

Playing Experience

Although not a replacement for a finely crafted wooden instrument, the 3D printed violin turned out to be playable and enjoyable. For beginners, hobbyists, or makers curious about blending engineering with music, it’s an affordable and creative way to explore violin construction without the challenges of woodworking.

Conclusion

This experiment shows both the possibilities and limitations of additive manufacturing in music. While 3D printing won’t dethrone centuries of violin-making tradition, it opens new avenues for customization, accessibility, and experimentation.

At FacFox, we help makers, designers, and innovators bring ideas like this to life. Whether you want to try functional prototypes, advanced composite materials, or custom artistic creations, our professional 3D printing services-from FDM to SLA, SLS, MJF, and even metal printing-are here to support your journey. Let’s transform your imagination into reality.

Solution

- Step 1: The 1/4-size violin model was downloaded from MakerWorld and design details were reviewed.

- Step 2: PETG GF filament was dried, the printer was calibrated, and settings were optimized for reinforced material.

- Step 3: The parts were sliced, supports were added, and about 1 kg of filament and 40 hours of print time were used.

- Step 4: Printed parts were cooled, removed, and supports were cleaned.

- Step 5: Components were assembled, bonded, and hardware pieces were installed.

- Step 6: Strings were mounted, the violin was tuned, and playability was evaluated.