- ¤ÄćNational Day & Mid-autumn holiday on Oct.1-8th. New orders will not be shipped until Oct.9!

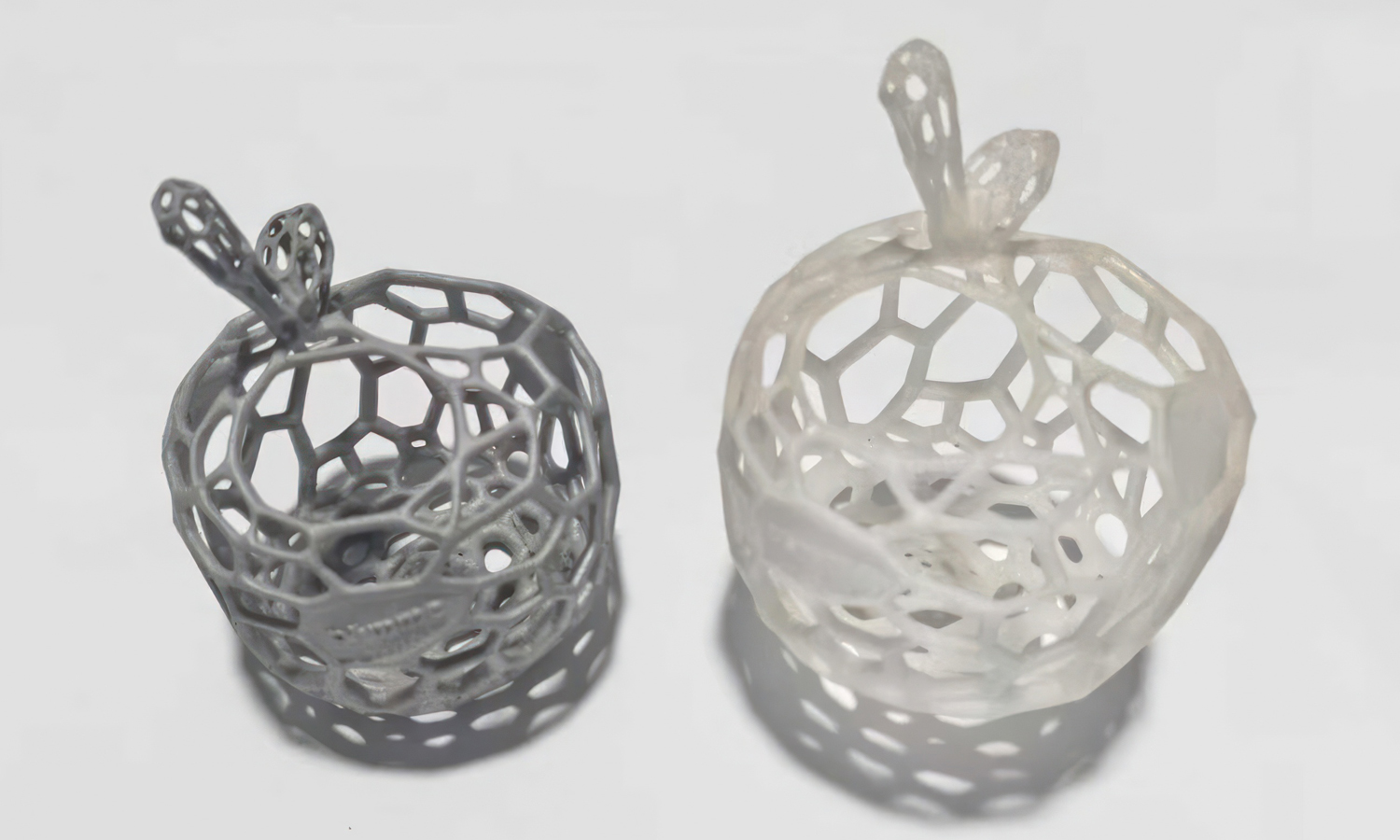

- SLA 3D Printed Display Base with Steps and Organic Details

Material Resin, Metal

Quantity 1 pcs

Price Range $100-1,000

Lead Time 4 workdays

Gallery

About Project

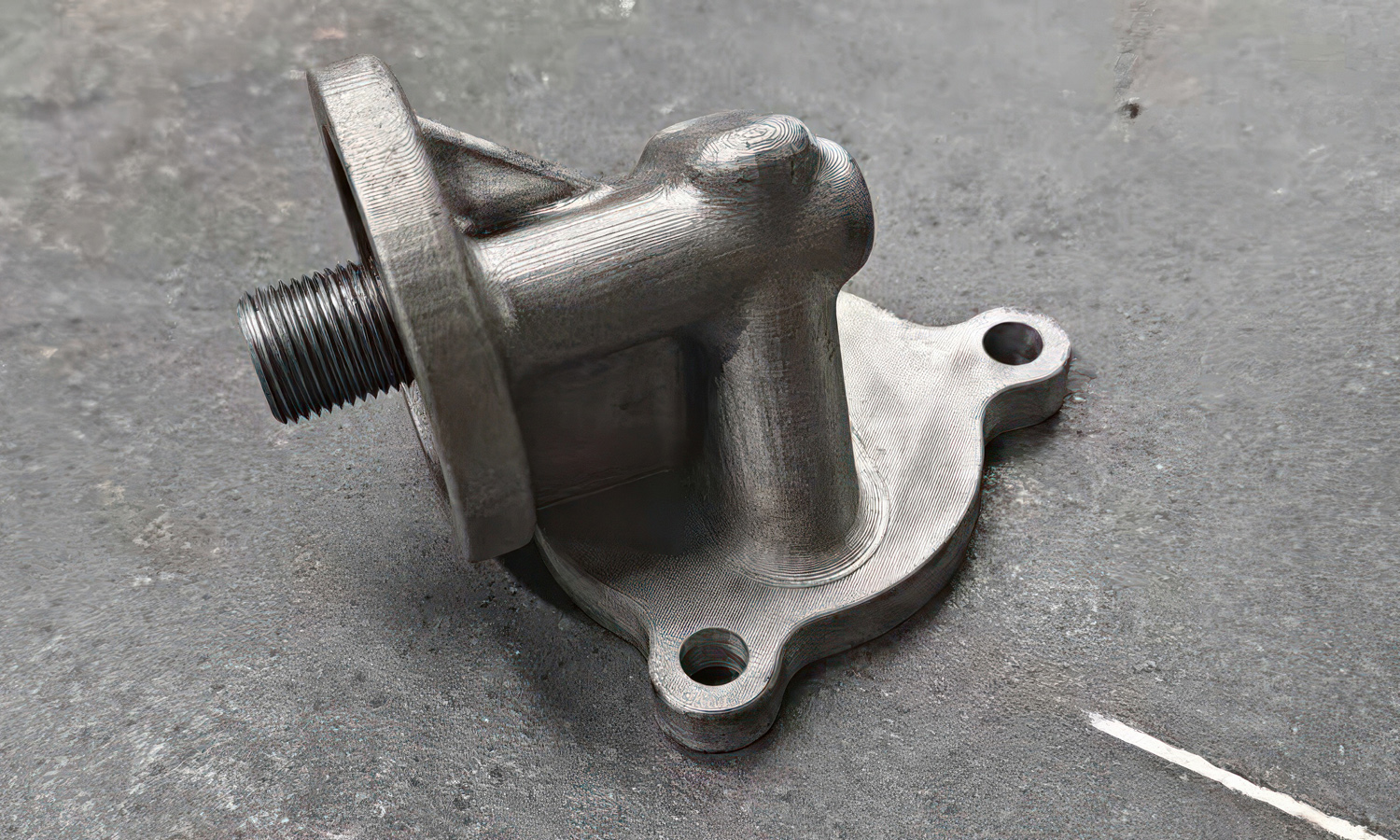

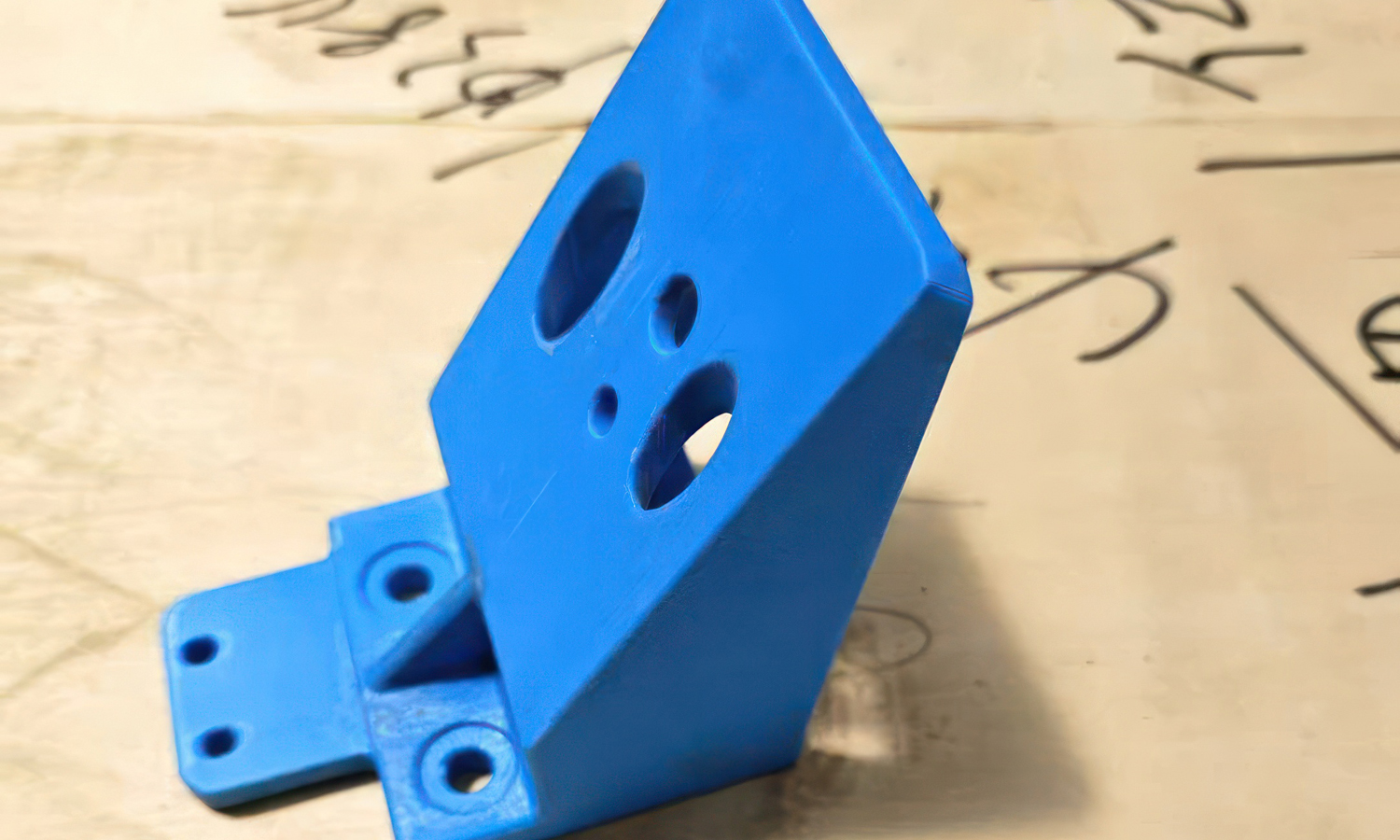

Wax 3D printing is often associated with exquisite jewelry and artistic creations-but its applications go far beyond. The photos here show functional mechanical prototypes including brackets, pump housings, and precision connectors. These complex forms were first produced with wax-like 3D printing materials, then cast into robust metal components.

By combining the design freedom of 3D printing with the proven reliability of investment casting, manufacturers gain:

- High dimensional accuracy for mechanical assemblies

- Seamless reproduction of fine details and internal features

- Material flexibility-from aluminum to stainless steel, brass, or even titanium

- Shorter lead times compared to traditional machining of complex parts

This means industries from aerospace, automotive, machinery, to medical devices can leverage the same technology once reserved for jewelers.

At FacFox, we provide professional wax 3D printing and casting services tailored to both designers and engineers. Whether it’s a delicate pendant or a heavy-duty industrial part, we help turn your digital design into a physical product-quickly and reliably.

¤æē Contact FacFox today to bring both beauty and strength into your next project.

Solution

- Step 1: The 3D models of the mechanical parts were designed in CAD software.

- Step 2: The models were sliced and prepared for 3D printing.

- Step 3: Wax-like resin was printed layer by layer to form precise prototypes.

- Step 4: Support structures were automatically generated and printed to maintain shape stability.

- Step 5: The printed parts were carefully removed from the build platform.

- Step 6: Support structures were detached and the surfaces were lightly cleaned.

- Step 7: The wax prototypes were assembled onto a casting tree.

- Step 8: The tree was coated with multiple layers of ceramic slurry to build a mold shell.

- Step 9: The mold shell was cured and hardened in a controlled environment.

- Step 10: The wax was melted and drained out, leaving a hollow cavity.

- Step 11: Molten metal was poured into the mold under high temperature.

- Step 12: The mold shell was broken away once the metal solidified.

- Step 13: The cast parts were cut off from the casting tree.

- Step 14: Surface finishing processes such as grinding and polishing were applied.

- Step 15: The final metal parts were inspected for dimensional accuracy and quality.