- New orders will NOT be shipped until Feb.5th (end of Chinese New Year holiday)

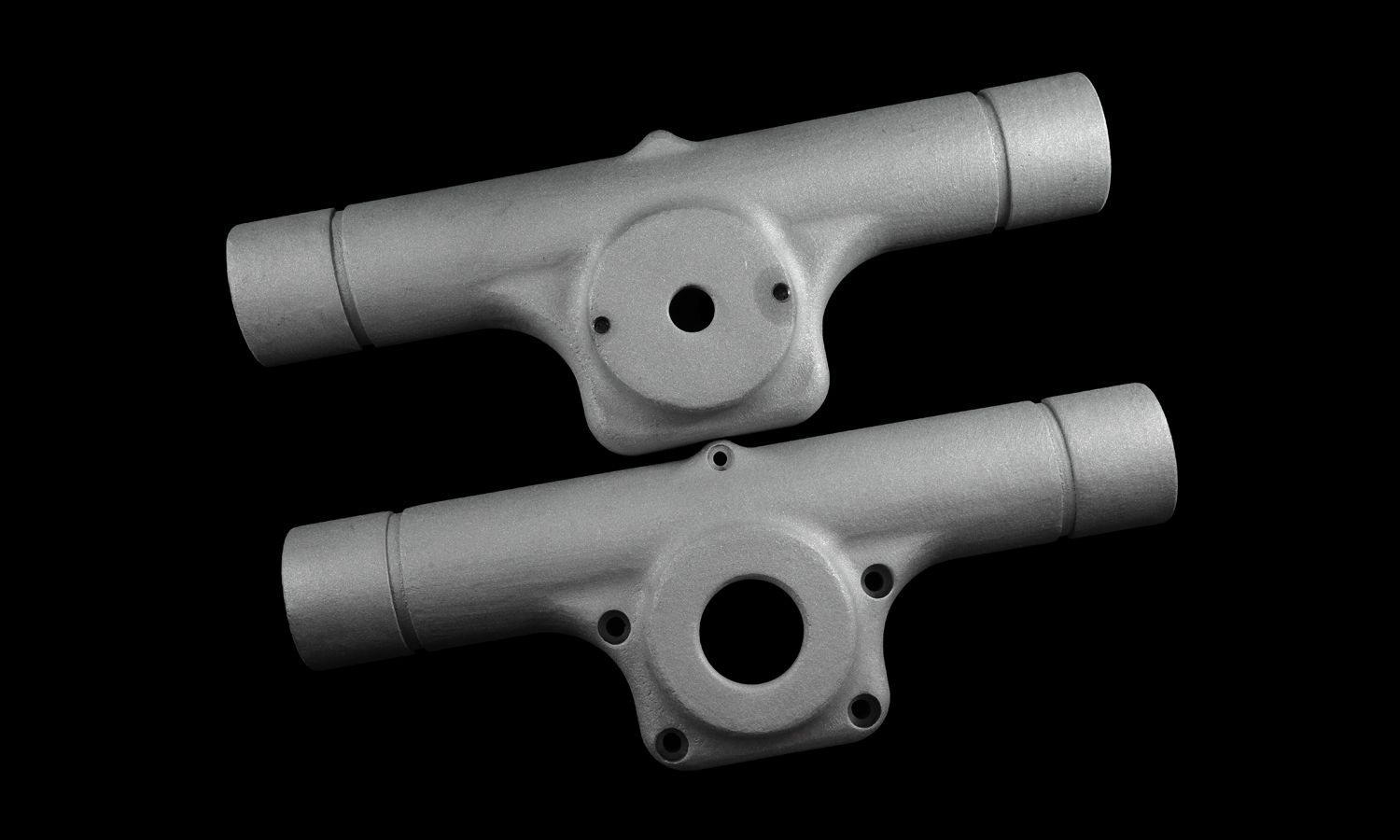

- SLM 3D Print Aluminum Saddle Clamp Customization

Gallery

About Project

Introducing our latest innovation, the SLM 3D Printed Cylindrical Flange Pipe Connector, designed to revolutionize the way you connect and secure pipes in your projects. Crafted with precision and cutting-edge technology, this component is a testament to modern engineering and customization capabilities.

Key Features

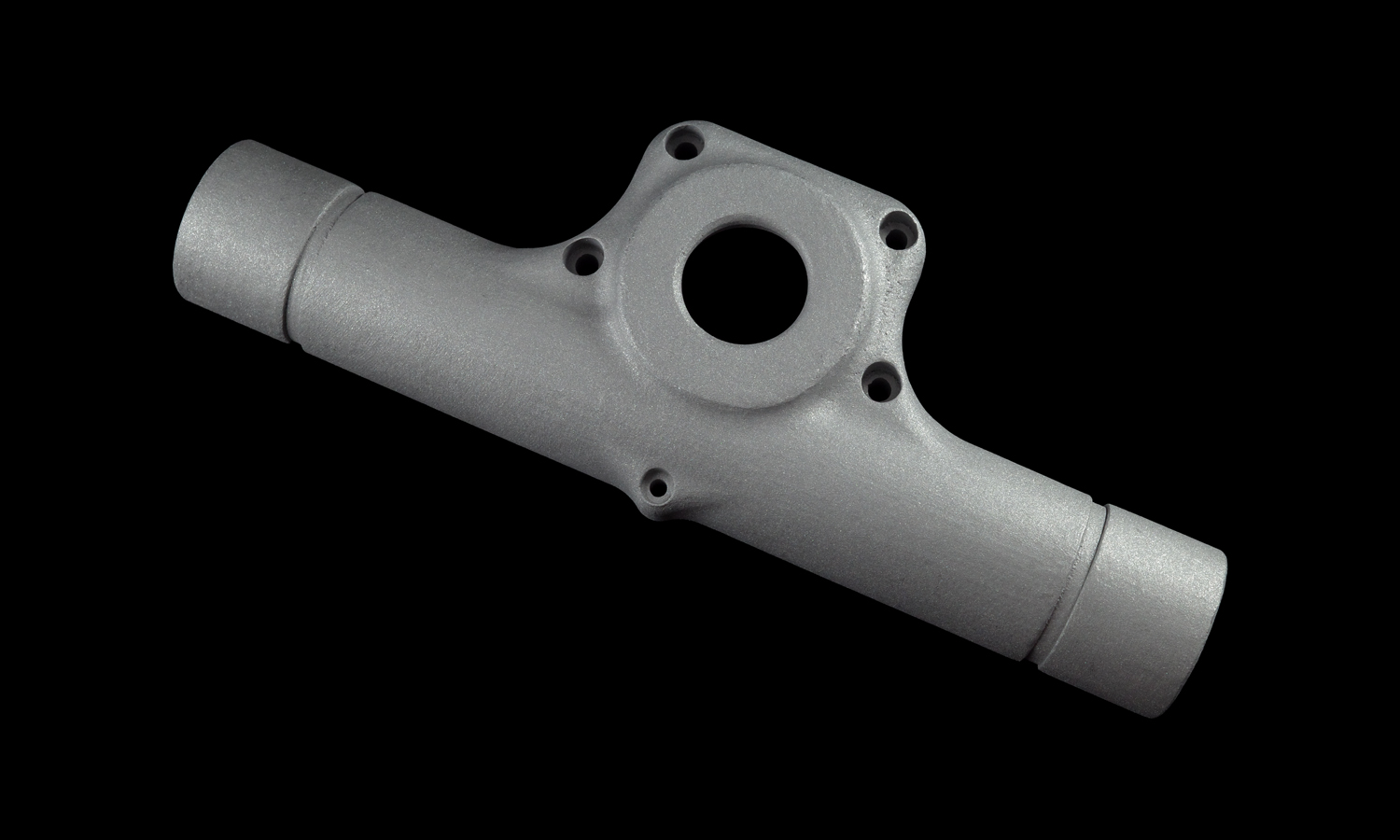

- Material: Fabricated from high-quality aluminum alloy, offering a perfect balance of lightweight, durability, and corrosion resistance, making it ideal for a variety of industrial applications.

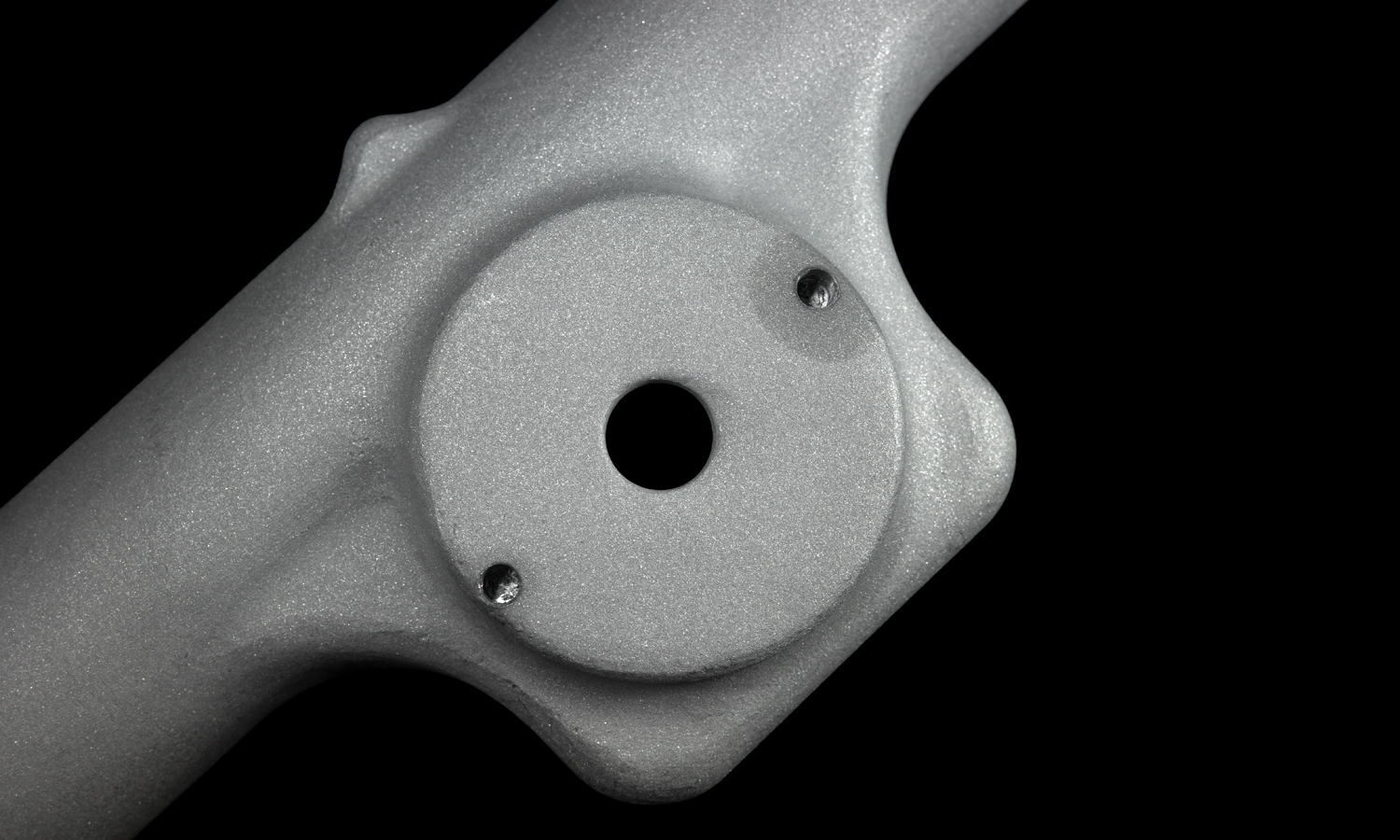

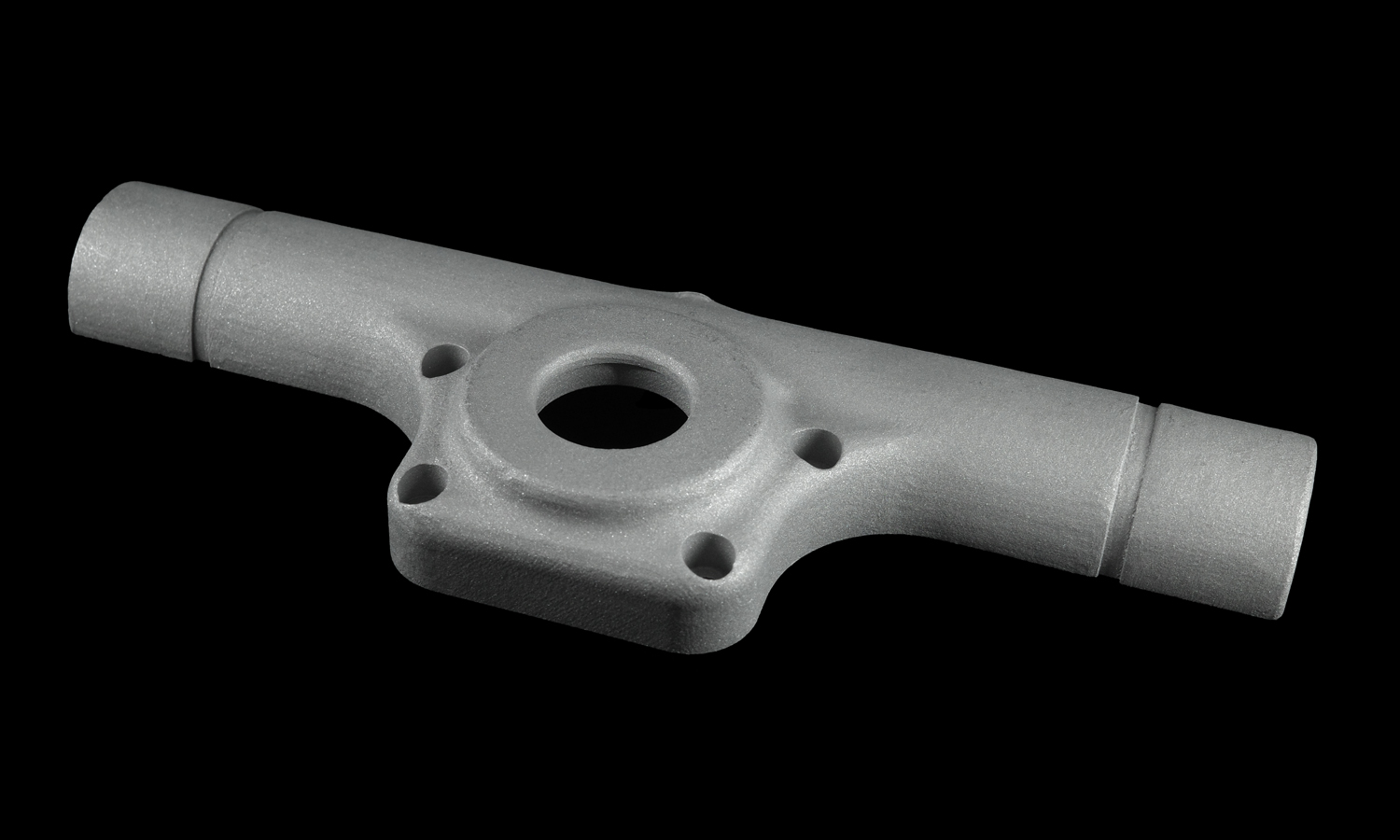

- Design: This connector features a hollow, elongated cylindrical structure with a central circular section. The top part includes three strategically placed holes, while the bottom part is designed with five holes, ensuring secure and stable attachment. These holes are essential for mounting and connecting the flange to other components or surfaces.

- Functionality: The semi-circular cutouts provide a snug fit around pipes or cylindrical objects, ensuring robust support and minimal friction. This design facilitates smooth operation and reliable performance in mechanical systems.

Customization and Post-Processing

- Allowance for CNC Machining: Each connector is produced with an allowance, allowing clients to further CNC machine the parts to achieve precise dimensions. This flexibility ensures that every connector meets the specific needs of your project.

- Surface Polishing and Threading: After 3D printing, the raw finish of the connectors is rough, providing a starting point for additional polishing and threading. Clients can CNC machine the parts to thread the holes, ensuring a polished and refined finish.

Enhance Your Projects with FacFox’s Metal 3D Printing Service

At FacFox, we specialize in delivering top-tier metal 3D printing solutions that bring your designs to life with unparalleled precision and quality. Our expertise in Selective Laser Melting (SLM) technology allows us to create highly customized parts tailored to your exact specifications.

Whether you need parts with allowances for further machining or intricate designs polished to perfection, FacFox is your go-to partner. Our comprehensive services include raw finishing, detailed post-processing, and everything in between. Experience the future of manufacturing with FacFox’s metal 3D printing services and elevate your projects to new heights.

Contact us today to learn how FacFox can transform your ideas into reality with our state-of-the-art technology!

Solution

- Step 1: Design. The 3D model of the Cylindrical Flange Pipe Connector, featuring a hollow, elongated cylindrical structure with a central circular section.

- Step 2: Slice Preparation. The 3D model was sliced into thin layers using specialized software. The slicing parameters, such as layer thickness and hatch spacing, were optimized for the SLM process and the desired part properties.

- Step 3: Powder Bed Preparation. A uniform layer of aluminum alloy powder was spread onto the build platform using a recoating blade.

- Step 4: Laser Melting. A high-powered laser beam was directed onto the powder bed, selectively melting the powder according to the slice data. This process was repeated layer by layer, building the part from the bottom up.

- Step 5: Part Removal. Once the entire part was built, the build platform was lowered, and the unsintered powder was removed. The part was then carefully extracted from the build chamber.

- Step 6: Debinding. Any residual powder or support structures were removed using a suitable debinding process.

- Step 7: Heat Treatment. The part was subjected to a heat treatment process to improve its mechanical properties, such as strength and ductility.

- Step 8: Surface Finishing (optional). The part’s surface was further processed to achieve the desired finish. This could include grinding, polishing, or other surface treatments as per customer requirements.

- Step 9: CNC Machining (optional). The part was machined using CNC equipment to achieve precise dimensions, thread the holes, and incorporate any additional features specified by the customer.