- ColorJet 3D Printed Full-color Black Myth Zhu Bajie Sandstone

- DMLS 3D Printed Titanium Bike Saddle Clamp Kit

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 8 workdays

Gallery

About Project

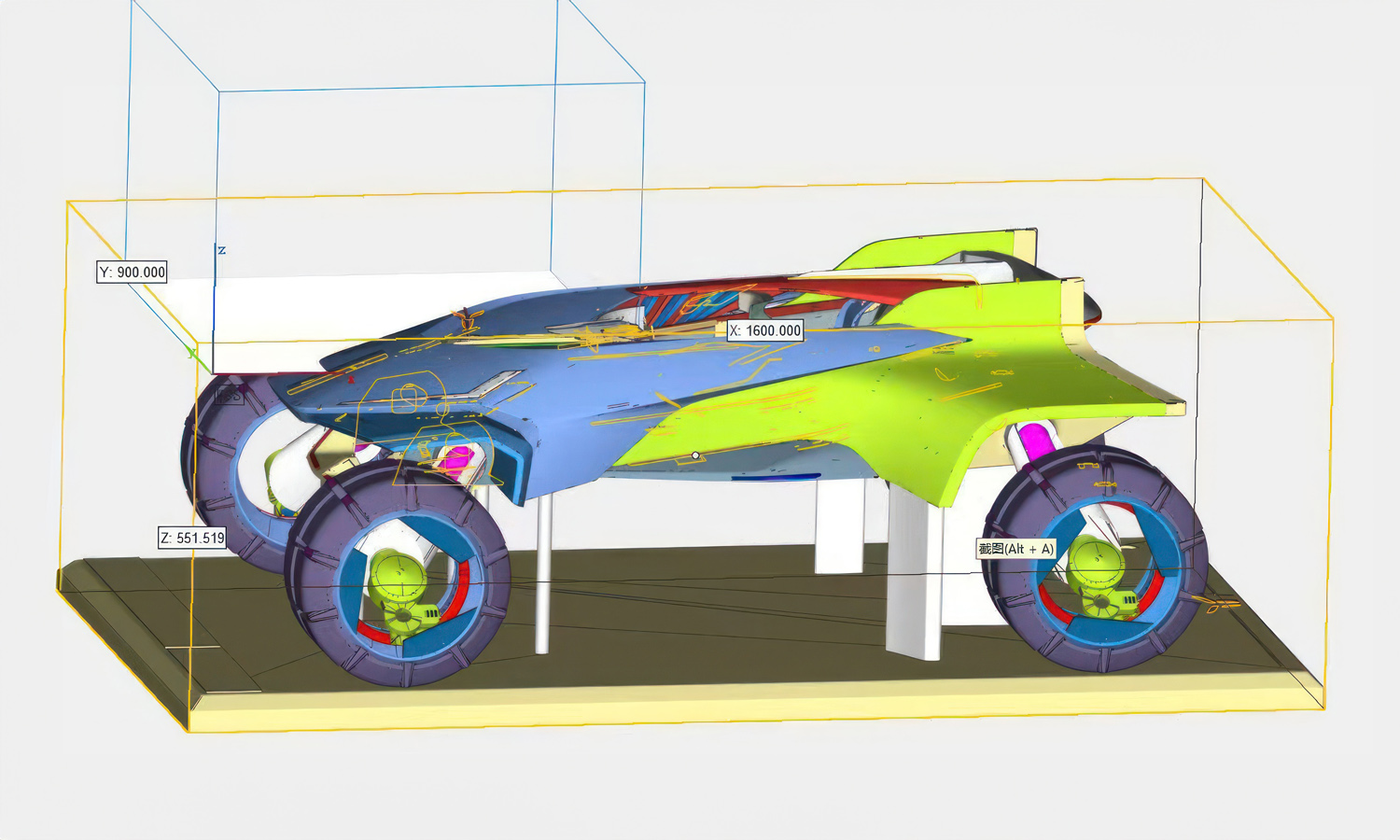

Introducing a groundbreaking achievement in automotive design and 3D printing technology: a full-scale race car concept prototype, meticulously crafted using SLA 3D printing. This innovative vehicle showcases a futuristic, off-road aesthetic, boasting large tires and exceptional ground clearance.

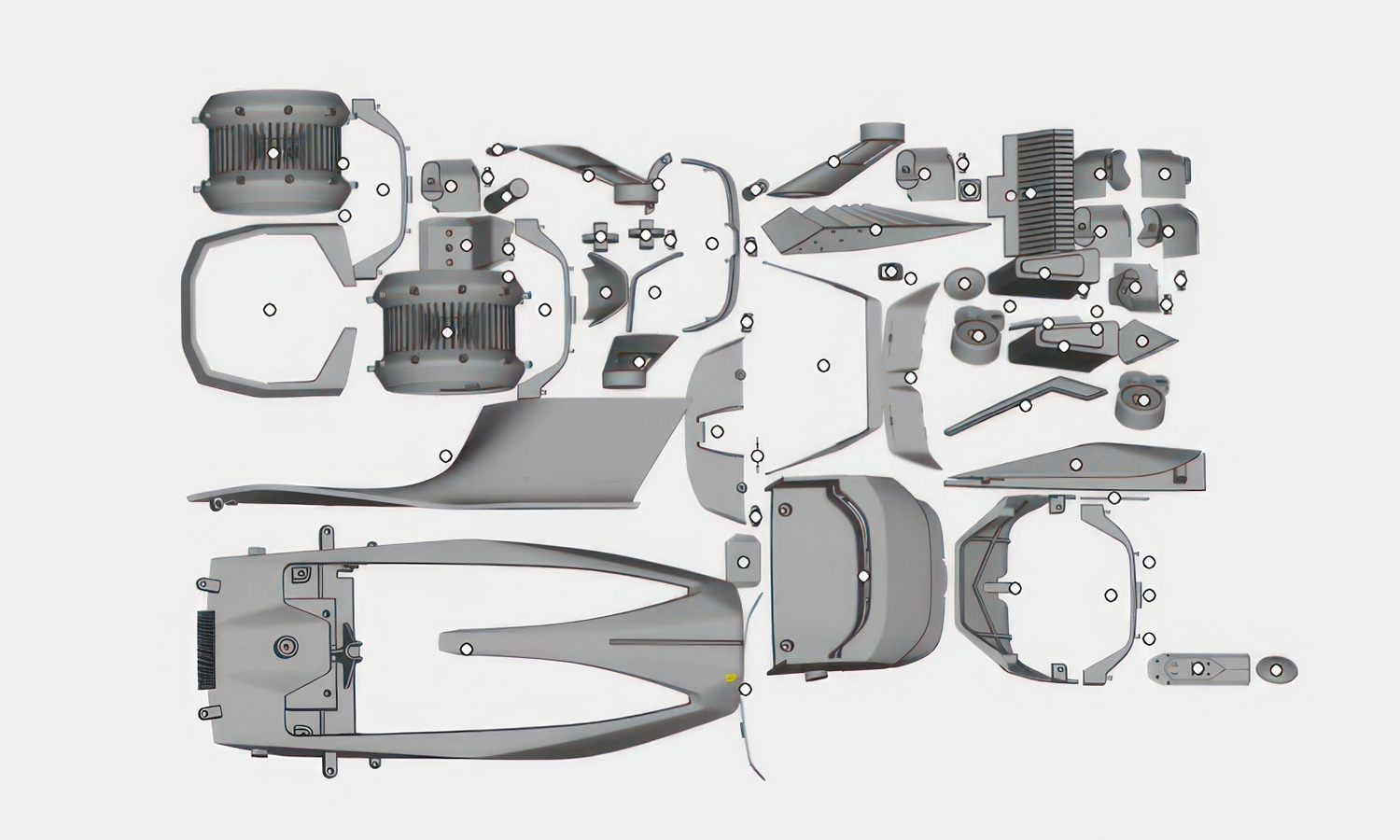

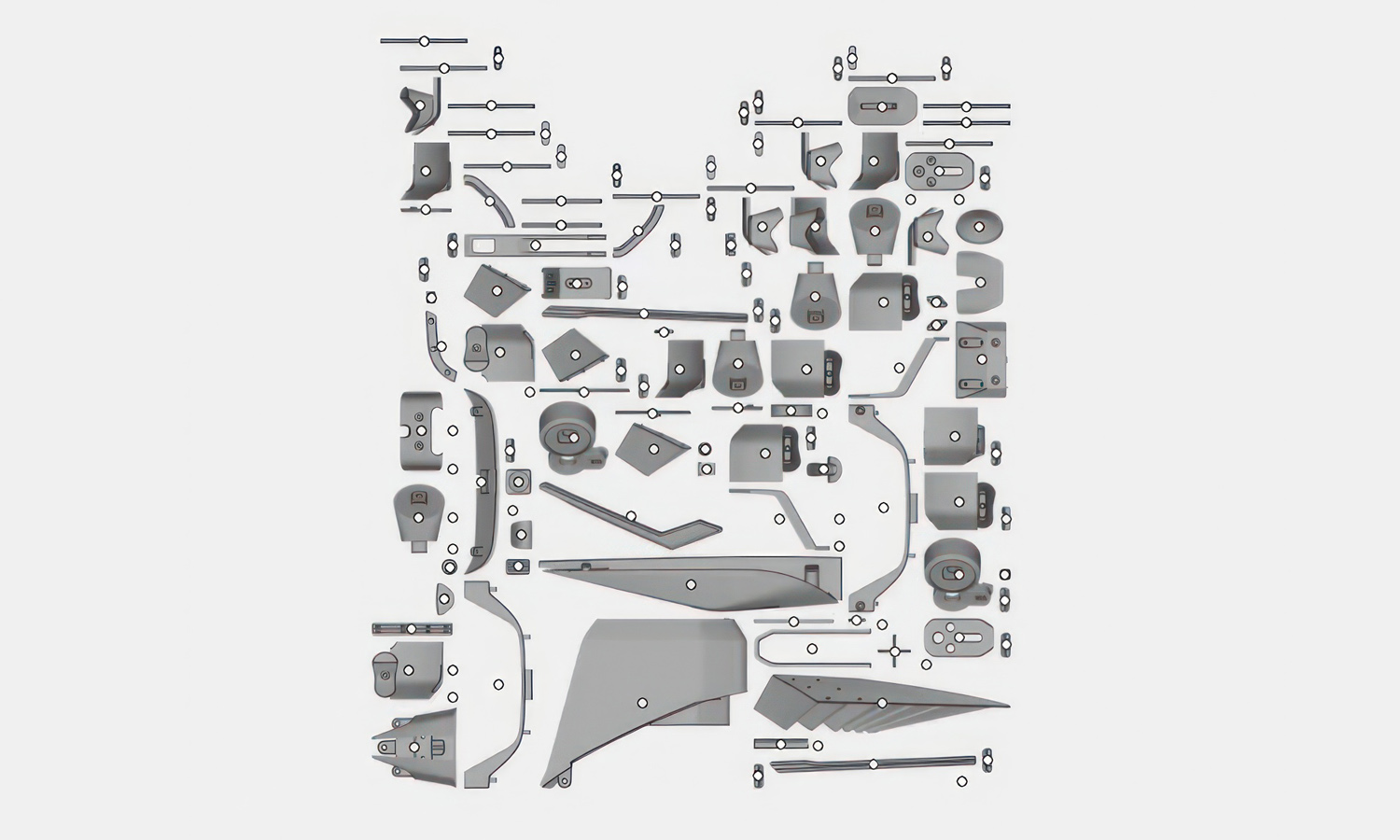

The creation of this remarkable prototype involved a complex process. The model was divided into over 400 individual parts, each requiring careful consideration of material selection and size. By sorting the parts according to these criteria, we ensured optimal printing efficiency and accuracy.

The printing process itself was a marvel of precision. Each part was meticulously printed using SLA 3D printing technology, resulting in exceptional detail and surface finish. Once printed, the parts were carefully organized into separate baskets, numbered according to the blueprints to maintain order and facilitate assembly.

The final stage of the process involved post-processing. This crucial step included cleaning, sanding, and finishing the parts to achieve the desired level of smoothness and appearance. Through meticulous attention to detail, we transformed these individual components into a cohesive and visually stunning race car prototype.

This project demonstrates the immense potential of 3D printing in the automotive industry. FacFox offers a wide range of 3D printing services tailored to meet the unique needs of automotive manufacturers and designers. Whether you’re developing concept prototypes, functional components, or production-ready parts, our expertise and advanced technology can help you bring your vision to life.

Solution

- Step 1: Model Creation and Preparation. The initial concept for the race car was designed and developed using computer-aided design (CAD) software. The 3D model was then divided into 400+ individual parts to facilitate printing and assembly.

- Step 2: Material Selection and Sorting. The appropriate materials for each part were carefully selected based on factors such as strength, durability, and aesthetic requirements. The parts were sorted according to their materials and size to optimize the printing process.

- Step 3: 3D Printing. Each part was printed using SLA 3D printing technology, which involves projecting a laser beam onto a liquid resin bath to solidify the desired shape layer by layer. The printed parts were carefully removed from the resin bath and washed to remove any excess material.

- Step 4: Post-Processing. The printed parts were cleaned, sanded, and finished to achieve the desired surface quality and smoothness. Any imperfections or defects were corrected during this stage.

- Step 5: Assembly. The individual parts were assembled together according to the original design and blueprints. Any necessary fasteners or connectors were used to secure the parts in place.

- Step 6: Final Inspection. The completed race car prototype was thoroughly inspected to ensure that it met all design specifications and quality standards. Any necessary adjustments or modifications were made at this stage.