- SLA 3D Printed and Painted Resin Durian Fake Food Model

- SLA 3D Printed Resin Chinese Furniture Miniature

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 7 workdays

Gallery

About Project

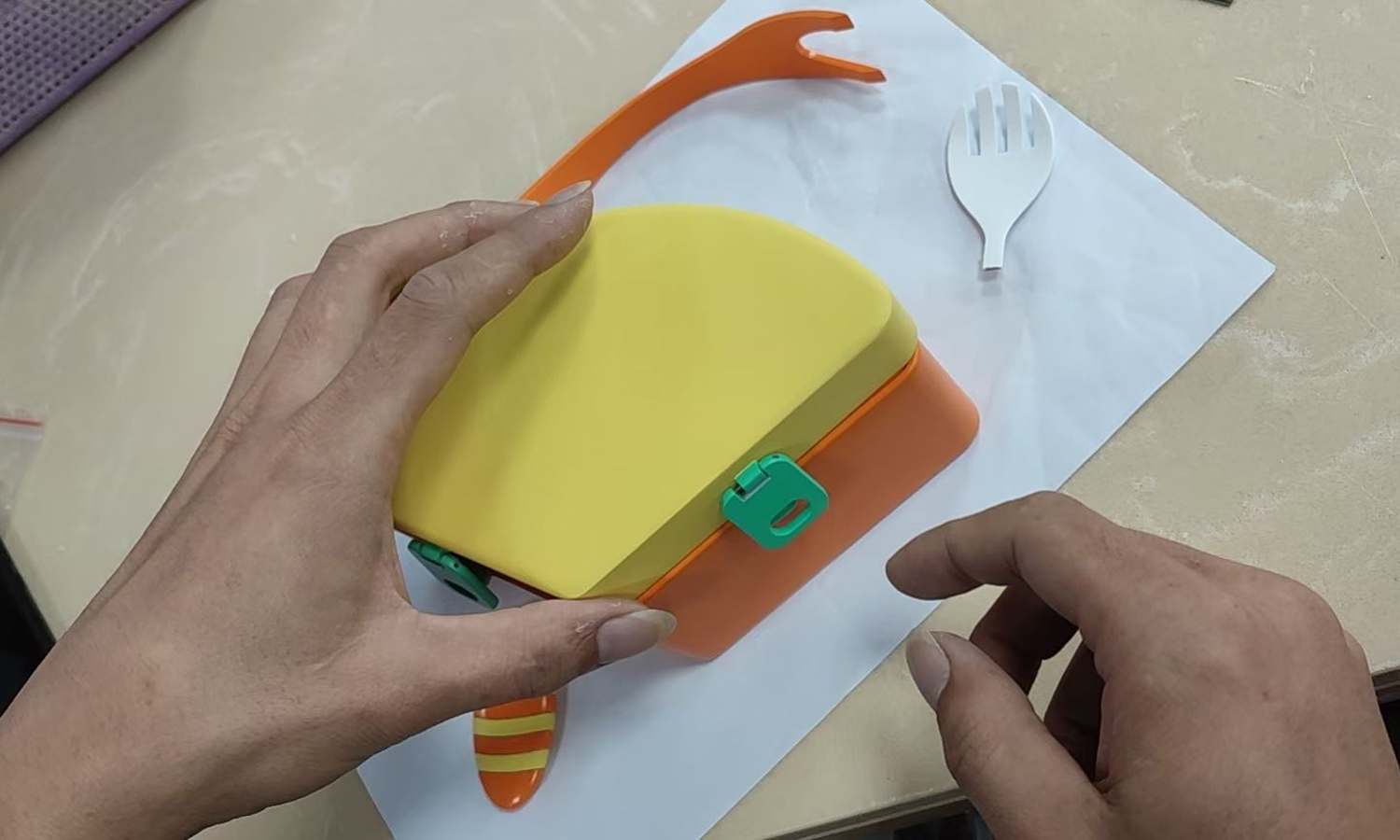

Are you looking for a fun and creative way to pack your kidsвҖҷ lunch? Do you want to surprise them with a unique and adorable tableware set that they will love? If so, you might be interested in the SLA 3D printed carrot-theme lunch box children tableware from FacFox.

This tableware set is designed to use the color scheme of carrot, with three sectors that can be placed as a round piece, or nested into each other like the Matryoshka dolls. The largest sector has a handle and a cap, with a buckle to keep it securely closed. The other two sectors can hold different kinds of food, such as sandwiches, fruits, snacks, or salads. The set also comes with a cute fork and spoon, also in the color of carrot, that fit inside the cap.

The tableware set is made of resin, using the SLA 3D printing technology. SLA stands for stereolithography, which is a process that uses a laser to cure liquid resin into solid objects. SLA 3D printing can produce high-resolution and smooth-surfaced models, with intricate details and complex shapes. The resin material is also durable, lightweight, and easy to clean.

The tableware set is a display model for product development, created by FacFox, a leading company in 3D printing and prototyping services. FacFox can help you turn your ideas into reality, with fast and affordable solutions for consumer products. Whether you need a prototype, a small batch, or a mass production, FacFox can handle it with their advanced 3D printing machines and experienced engineers. You can choose from a variety of materials, colors, and finishes, and get a quote online within minutes.

If you are interested in the SLA 3D printed carrot-theme lunch box children tableware, or any other 3D printing and prototyping services, you can visit the FacFox website [facfox.com] for more information. You can also contact them by email, phone, or chat, and they will be happy to assist you with your project. FacFox is your reliable partner for 3D printing and prototyping, with high quality, low cost, and fast delivery.

Solution

- Step 1: The 3D model of the tableware set was designed using a CAD software, such as SolidWorks, Blender, or SketchUp. The model was then exported as an STL file, which is a standard format for 3D printing.

- Step 2: The STL file was imported into a slicing software, such as ChiTuBox, Cura, or PrusaSlicer. The slicing software prepared the model for printing by dividing it into thin layers, and generating the instructions for the 3D printer. The slicing software also allowed the user to adjust the printing parameters, such as the layer height, the orientation, the support structures, and the infill density.

- Step 3: The sliced file was transferred to the SLA 3D printer, such as the Formlabs Form 3, the Anycubic Photon, or the Elegoo Mars. The SLA 3D printer used a laser to cure the liquid resin into solid objects, layer by layer. The resin was contained in a vat, and the build platform was lowered into the vat. The laser scanned the cross-section of the model on the surface of the resin, and the resin was hardened by the light. The build platform then moved up slightly, and the next layer was cured. This process was repeated until the whole model was completed.

- Step 4: The printed model was removed from the build platform, and the excess resin was washed off with isopropyl alcohol. The model was then cured under a UV light to enhance its strength and durability. The support structures were also removed with a cutter or a plier, and the model was sanded and polished to smooth the surface and remove any defects.

- Step 5: The model was painted with acrylic paints, using an airbrush or a brush. The model was painted in the color of carrot, with orange for the body and green for the cap and the handle. The details, such as the eyes, the mouth, and the spots, were also painted to make the model more realistic and cute. The model was then coated with a clear varnish to protect the paint and give it a glossy finish.