Polyjet 3D Printing Services

Print your PolyJet/MJP parts with extremely versatille combination of multi-material and multicolor in as fast as 1 day!

PJ printing service starting at only $25!

Overview: How PolyJet/Multijet 3D printing works?

The Basics Of PolyJet/MJP 3D Printing Services

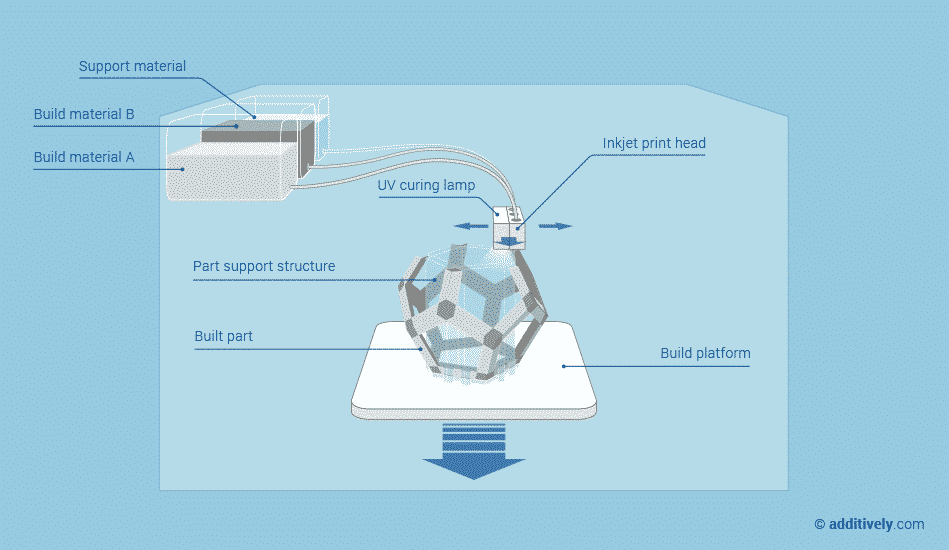

PolyJet(Stratasys’ Technology), or MultiJet Printing(3D Systems‘ Technology), works similarly to inkjet printing, but instead of jetting drops of ink onto paper, PolyJet 3D Printers jet layers of curable liquid photopolymer onto a build tray.

Inkjet print heads are used to jet liquid photopolymers onto a build platform. The material is immediately cured by UV lamps and solidified which allows to build layers on top of each other.

Where overhangs or complex shapes require support, the PolyJet 3D printer jets a removable support material, named FullCure 750/SUP706. The process of fine layer polymerization is repeated until the object is finished.

After the photopolymerization is completed, the batch is placed under a pressurized water jet. This allows any excess liquid or supports to be removed with a few human interactions.

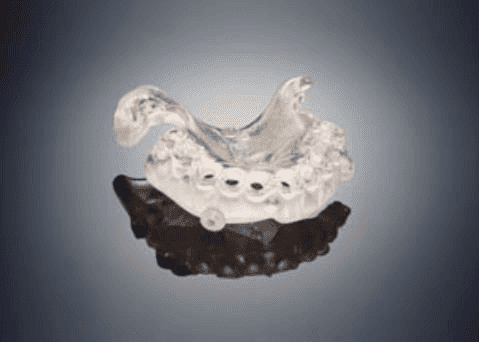

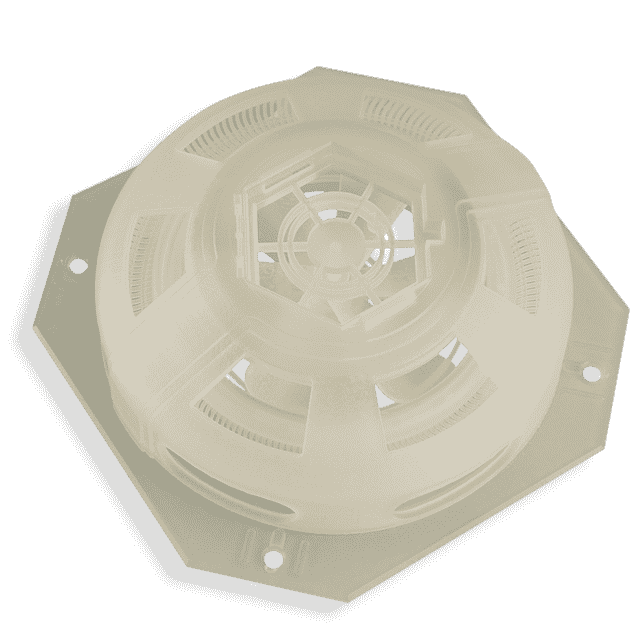

The final product has a naturally smooth surface which can be polished further to create near full transparency for the clear resin. 3D printed models and parts are ready to handle and use right out after the cleaning process, there is no need for post-curing.

Benefits Of PolyJet/MJP 3D Printing Services

PolyJet offers the unique ability to print parts and assemblies made of multiple materials, colors/transparency, hardness with different mechanical or physical properties, all in a single build.

PolyJet offers the unique ability to print parts and assemblies made of multiple materials, colors/transparency, hardness with different mechanical or physical properties, all in a single build.

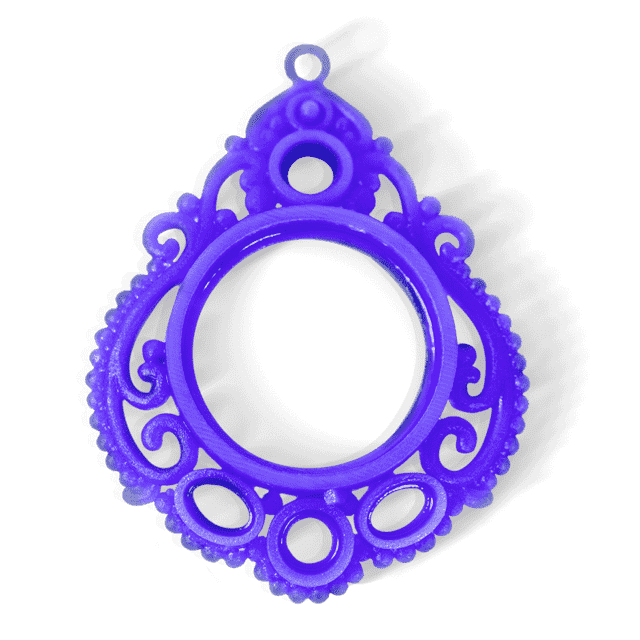

PolyJet technology enables horizontal layers of lowest 17 ┬Ąm, fine details, and ultra-thin walls down to 0.6 mm depending on the geometry of the part. That means PolyJet is capable of building very precise mechanical components, offering you high-quality prototypes for a shorter time to market.

Benefits Of Polyjet/MJP 3D Printing Services With FacFox

Our Polyjet/MJP services allow you to make 3D printed parts and prototypes in a wide range of materials. Prototypes made using this service can be used for engineering testing or as master patterns for urethane casting molds, even molds for rapid injection molding. You can also have metal 3D printed parts made using our DMLS 3D printing service.

PolyJet vs MJP

Features of PolyJet 3D Printing

Advantages

Drawbacks

PolyJet/MJP Processes

Printers & Parameters – Printers: Stratasys J750/Objet Series, 3D Systems Objet Series, Solidscape Series – Maximal build volume: 1000 x 800 x 500 mm(Objet 1000 Plus) – Minimum feature size: 0.05 mm Restrictions – Minimum layer thickness: 0.008 mm – Typical surface finish: 0.08 ŌĆō 10 microns RA – Accuracy: (+/- 0.1-0.2%) Pre-build planning Important decision on design is the orientation and support structures. This depends on: – Geometry: Optimize it to reduce supports and layer lines. – Areas that need great smoothness or post-processing

Available Materials

Available Finishes

The finish option with the quickest turnaround. Which normally includes:

- Removal of support: Supports are dissolved after printing. This is usually straight forward, however might require some extra effort for parts with complex geometric features.

- Painting

- Nano-painting

- UV Coating

- DonŌĆÖt see the finish you need? Submit an RFQ with ‘Suggest’ option, weŌĆÖll look into a finishing process for you.

PolyJet/MJP Applications

Prototypes With PolyJet/MJP, the prototype can be made using various materials/colors/transparency/hardness. Its extremely detail and smoothness makes it outform almost all other 3D Printing technology in terms of visual prototypes.

The heat tolerance and great mechanical properties of PolyJet/MJP digital materials let rapid molds possible to be printed directly, shortening the turnaround tremendously. Rapid Molds

PolyJet/MJP can be applied to make high-quality small batched products with varied requirements, ideal for small businesses that wishes to test the market’s reaction to thier newly developed products.Customized Products

Industries with PolyJet/MJP

Resources for PolyJet/MJP