Metal Casting Services

Sheet metal prototypes and low-volume production parts shipped in as fast as 2 days

Overview: How Metal Casting works?

The Basics Of Metal Casting Service

Metal Casting is a process in which an accelerated jet of hot plasma cuts through electrically conductive materials. The typical materials cut by this process include steel, aluminum, brass and copper, although other conductive metals can also be cut using this process.

Metal Casting is the fastest and most economical way to cut thick ferrous and non-ferrous metal sheets (over 0.75 inches). For thin (less than 0.75 inches) metals, non-conductive materials and parts with intricate cuts made using laser cutting would be the best choice.

Benefits of Metal Casting With FacFox

Our state-of-the-art CNC plasma cutter is equipped with a smaller nozzle and a thinner plasma arc than is typically found in such cutters. We are capable of providing near-laser precision on plasma-cut edges for materials that are up to 6 inches thick. Our Metal Casting device includes a precision CNC station and 24 automatic tool changer, so we can guarantee the fabrication quality of the products, which require little or no finishing.

Features of Metal Casting Service

Advantages

Drawbacks

Metal Casting Processes

Producing flat profiles, where the cut edges are at 90 degrees to the material surface. High powered cnc Metal Casting beds are configured in this way, able to cut profiles from metal plate up to 150 mm thick. The angular cutting capability of 3-dimensional Metal Casting can also be used to create countersunk holes and chamfer edges of profiled holes. The Metal Casting head usually remains stationary whilst the workpiece is fed through, and rotated around its longitudinal axis.2D Metal Casting

3D Metal Casting

Tube and section Metal Casting

Available Materials

Available Finishes

The finish option with the quickest turnaround.

Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. Surface finish is comparable to 125 uin Ra finish.

Abrasive blasting, more commonly known as sandblasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants.

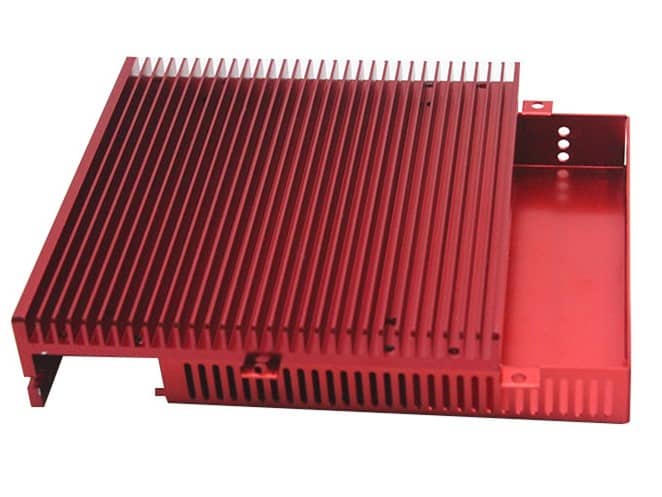

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in coating and is then cured under heat to allow it to flow and form a “skin”. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware and automobile and bicycle parts.

- Electroplating

- DonŌĆÖt see the finish you need? Submit an RFQ with ‘Suggest’ option, weŌĆÖll look into a finishing process for you.

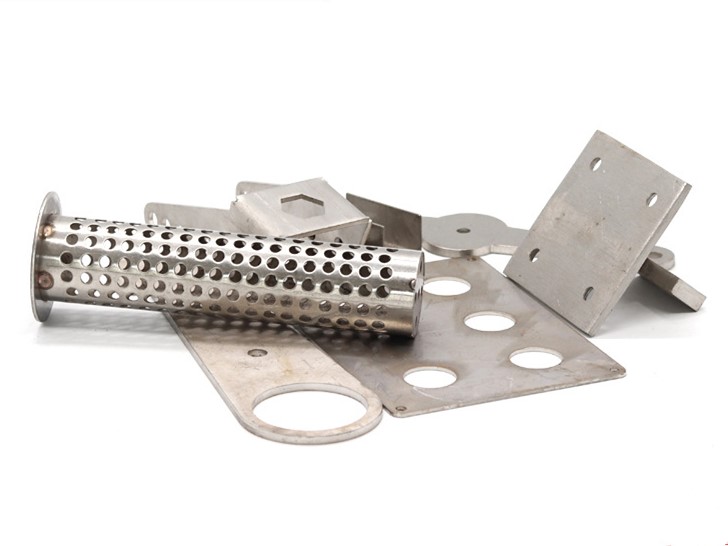

Metal Casting Applications

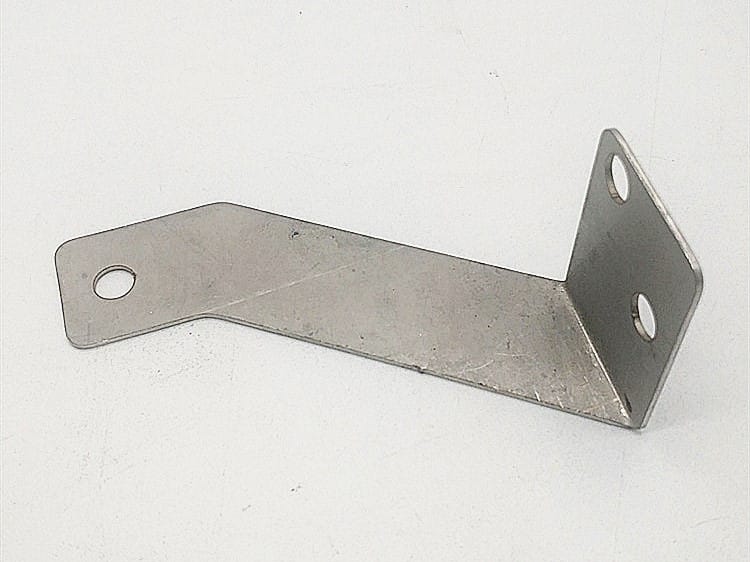

Whether you need a bracket, chassis, enclosure, or any other complex sheet metal design, weŌĆÖll ship 1 to 50+ prototypes in as fast as 4 days. Get the same great service of our prototyping shop higher volumes. Our low-volume production facility can produce up to 50 to 1,000+ sheet metal parts in as fast as 10 days. We provide a partial or complete prototype assembly in 2 to 3 weeks. We help coordinate the procurement of your custom and catalog parts to build your electro-mechanical assembly fast.Sheet Metal Prototypes

Sheet Metal Products

Multipart Assemblies

Industries with Metal Casting

Resources for Metal Casting