Insert molding Services

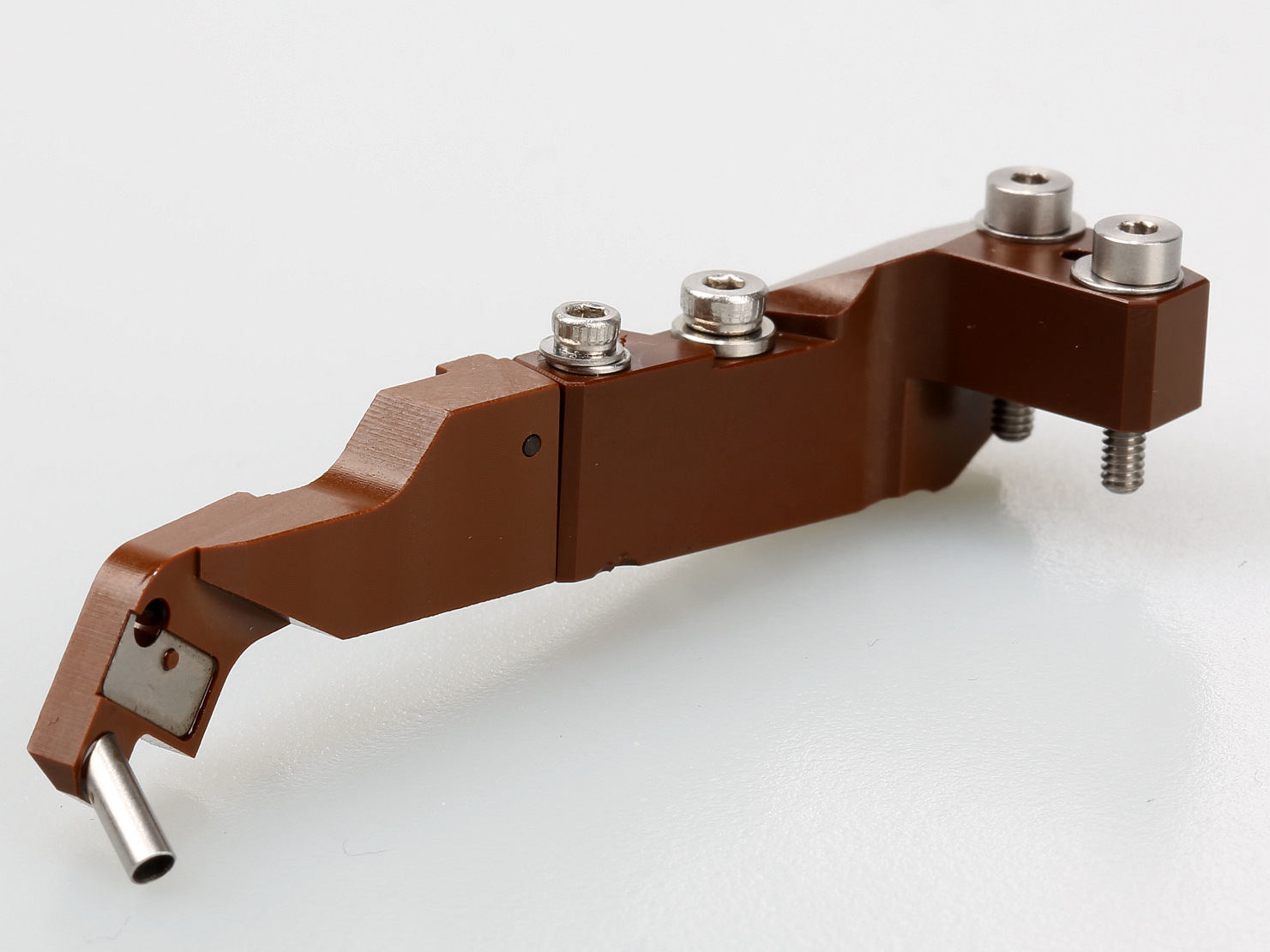

Thermoplastic material is molded around an insert piece or pieces placed in the plastic injection molding cavity, resulting in a single strongly bonded, integrated assembly

Overview: How Insert Molding works?

The Basics Of Insert Molding

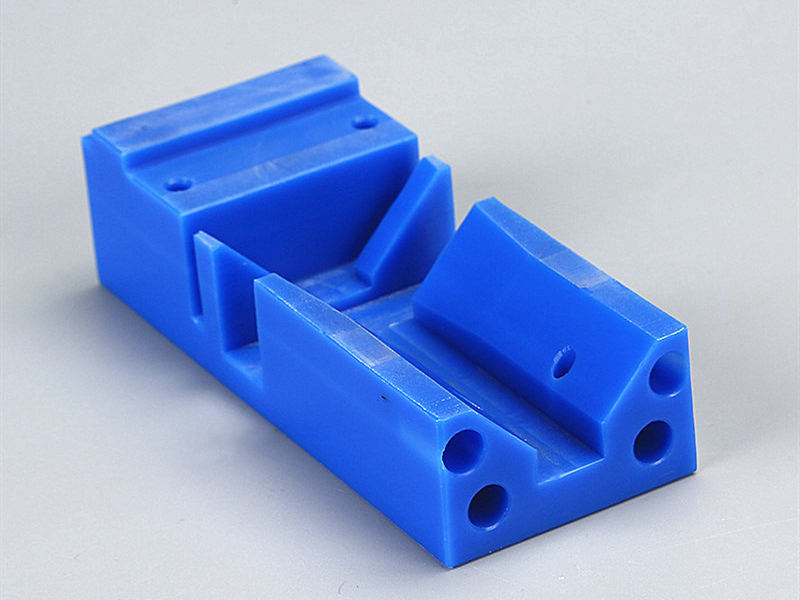

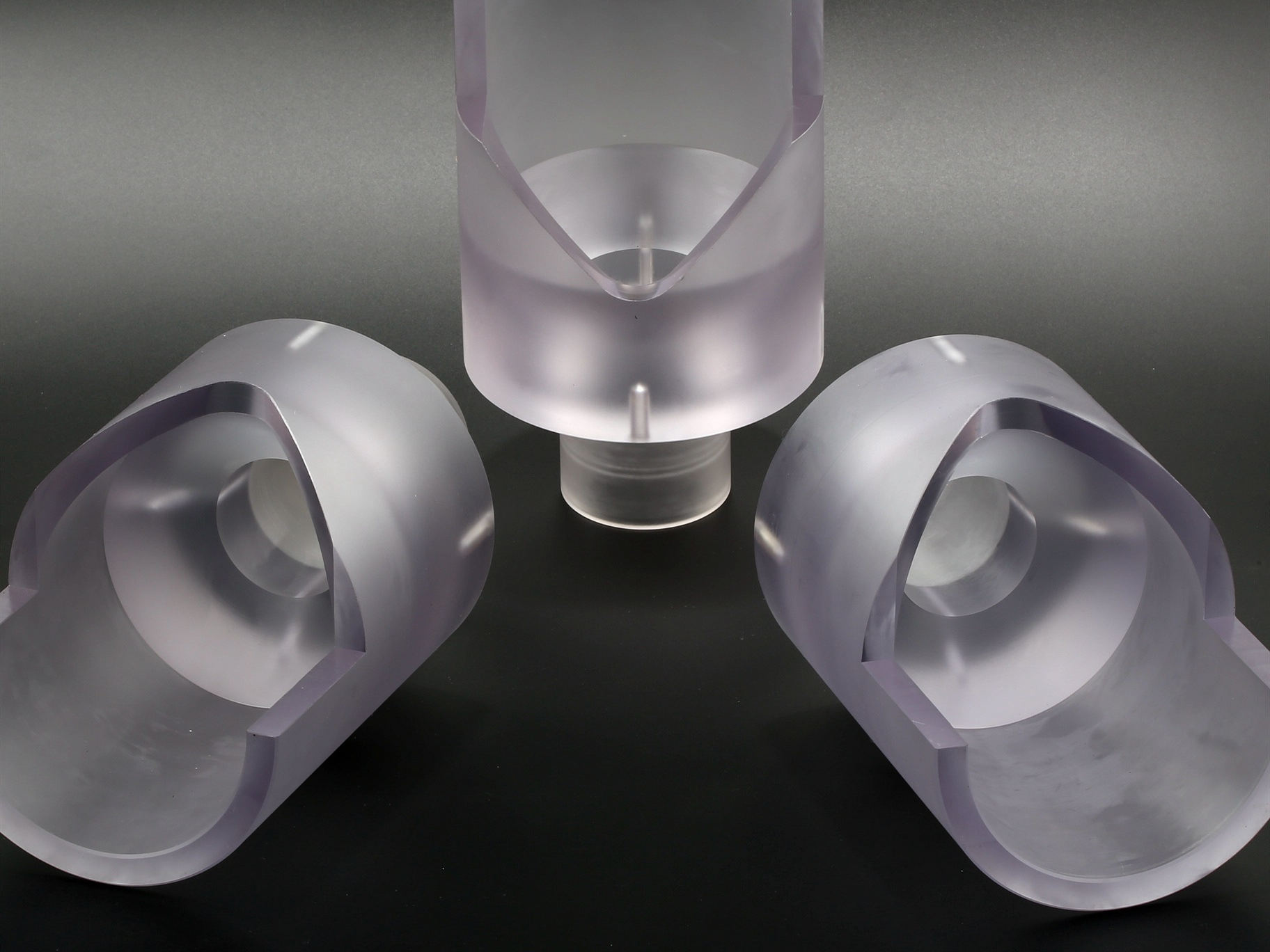

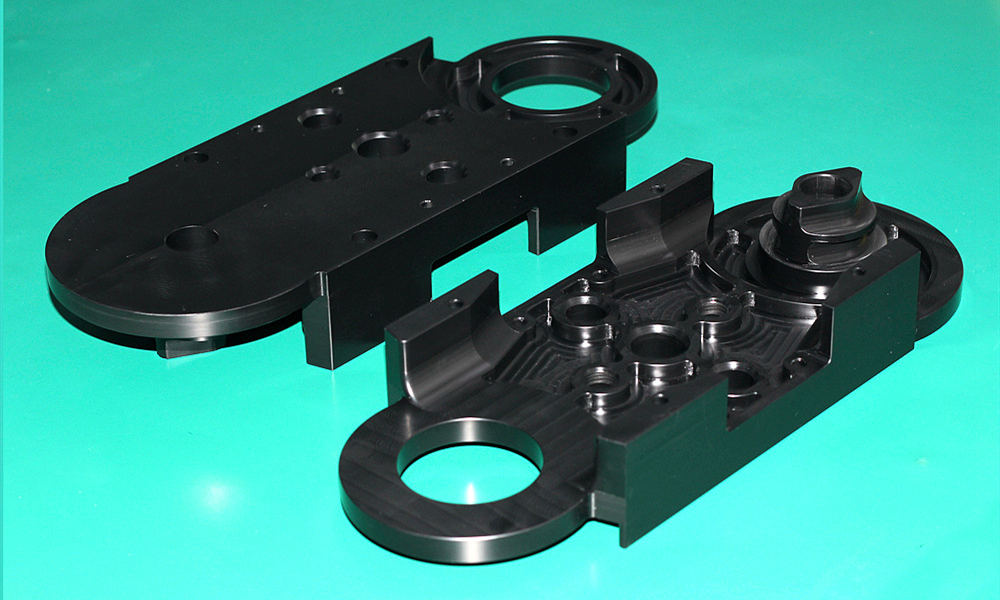

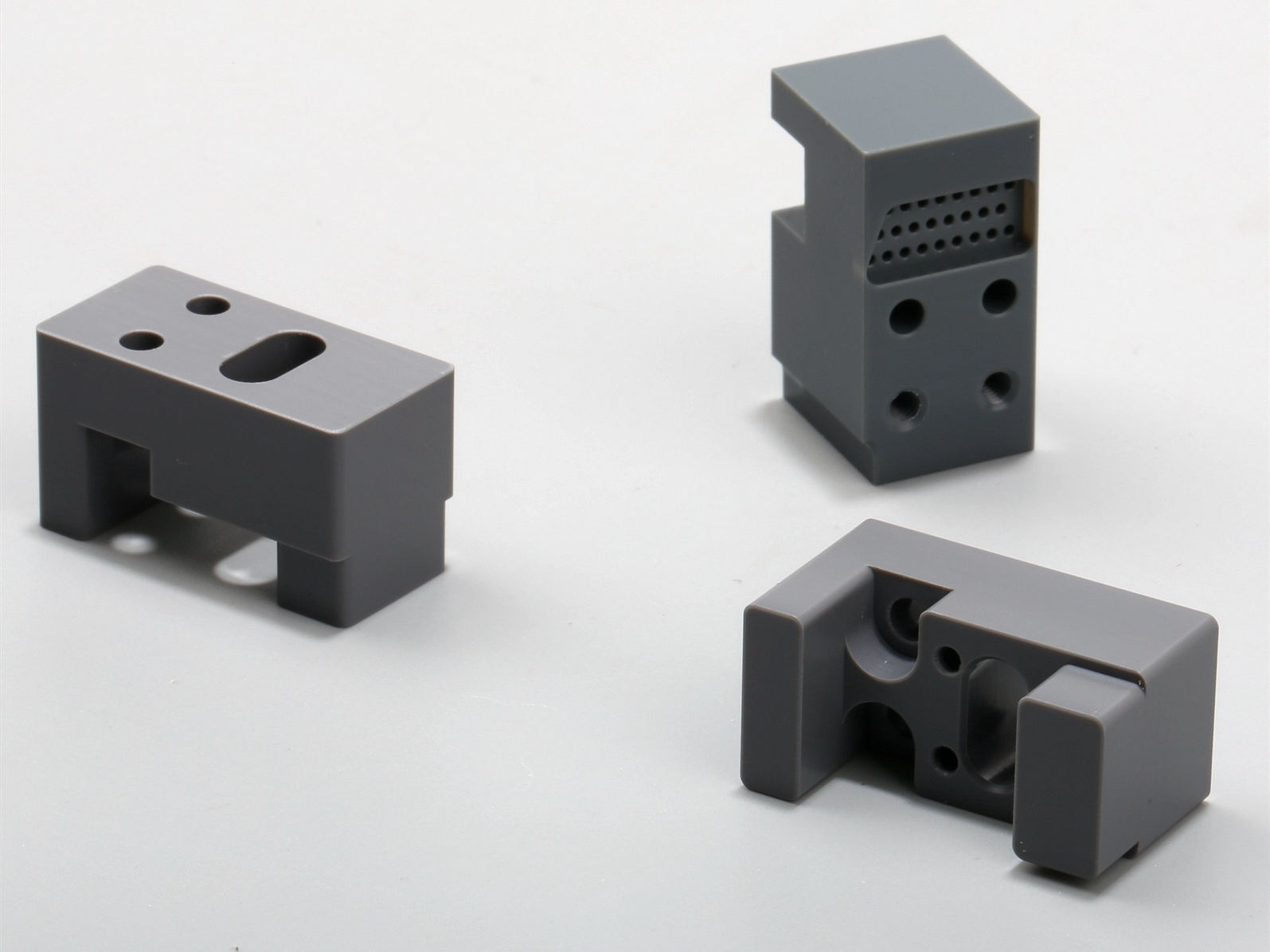

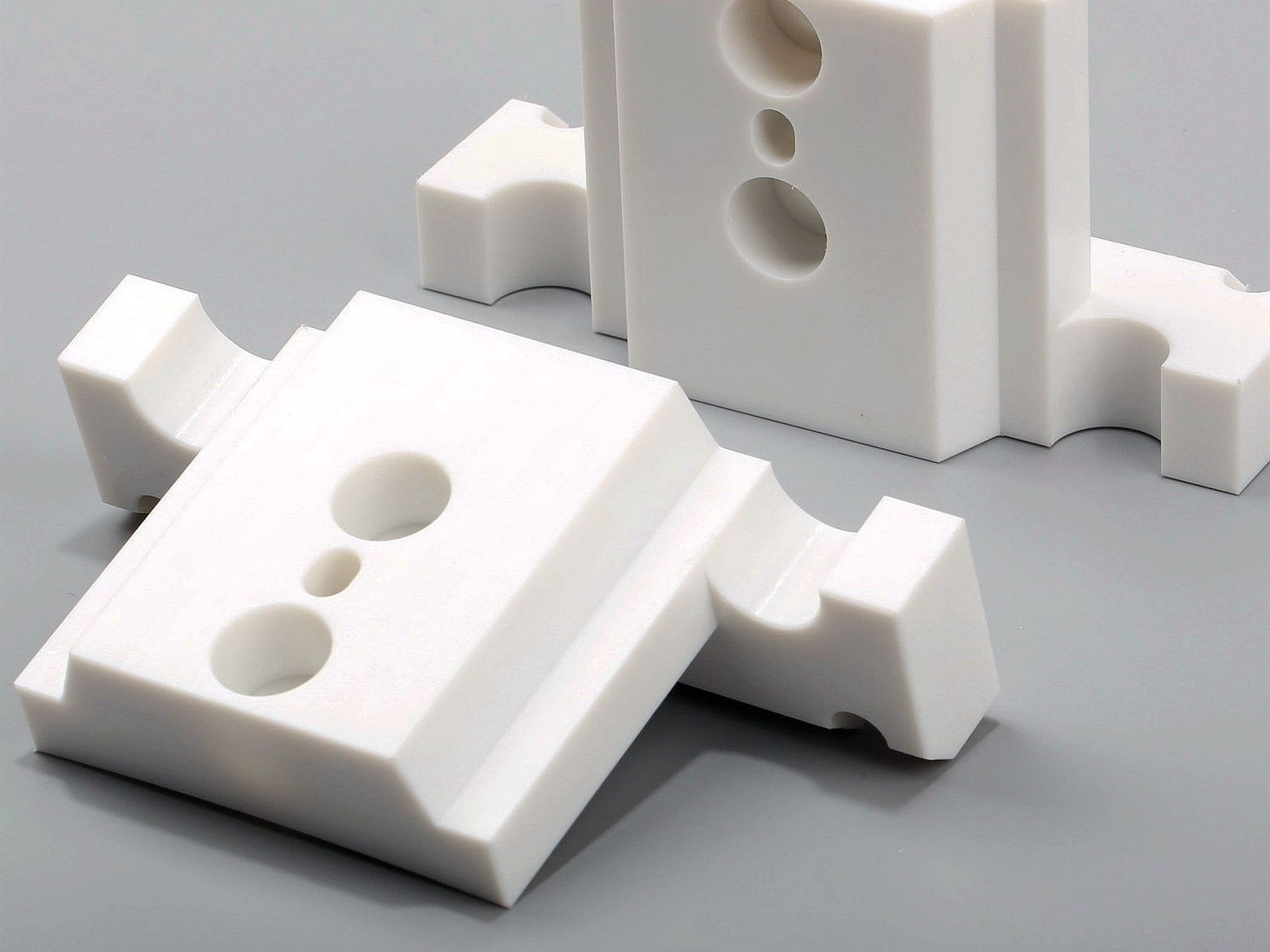

Plastic injection insert molding is a plastic injection molding process in which thermoplastic material is molded around an insert piece or pieces placed in the plastic injection molding cavity, resulting in a single strongly bonded, integrated assembly, with the insert or inserts encapsulated by the plastic.

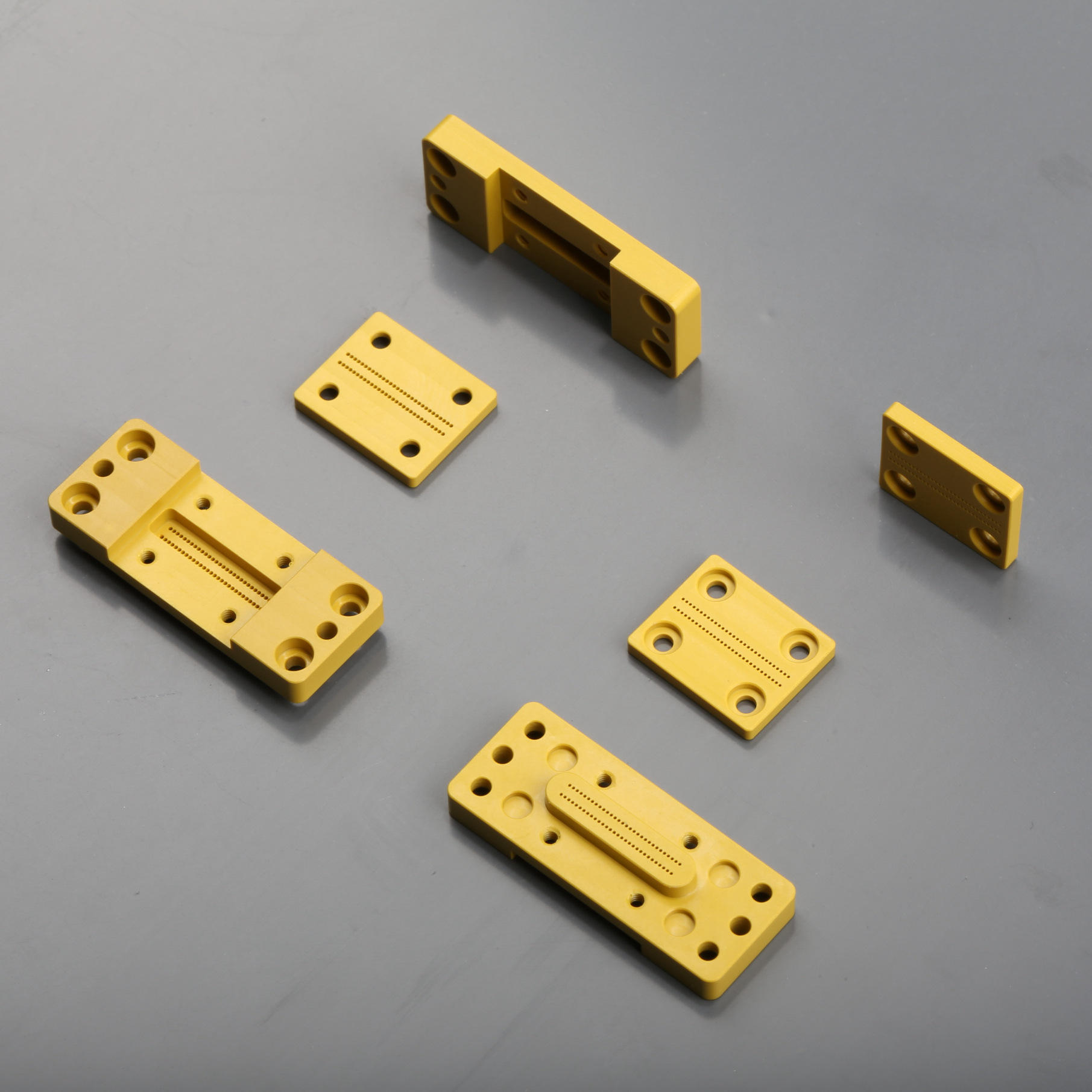

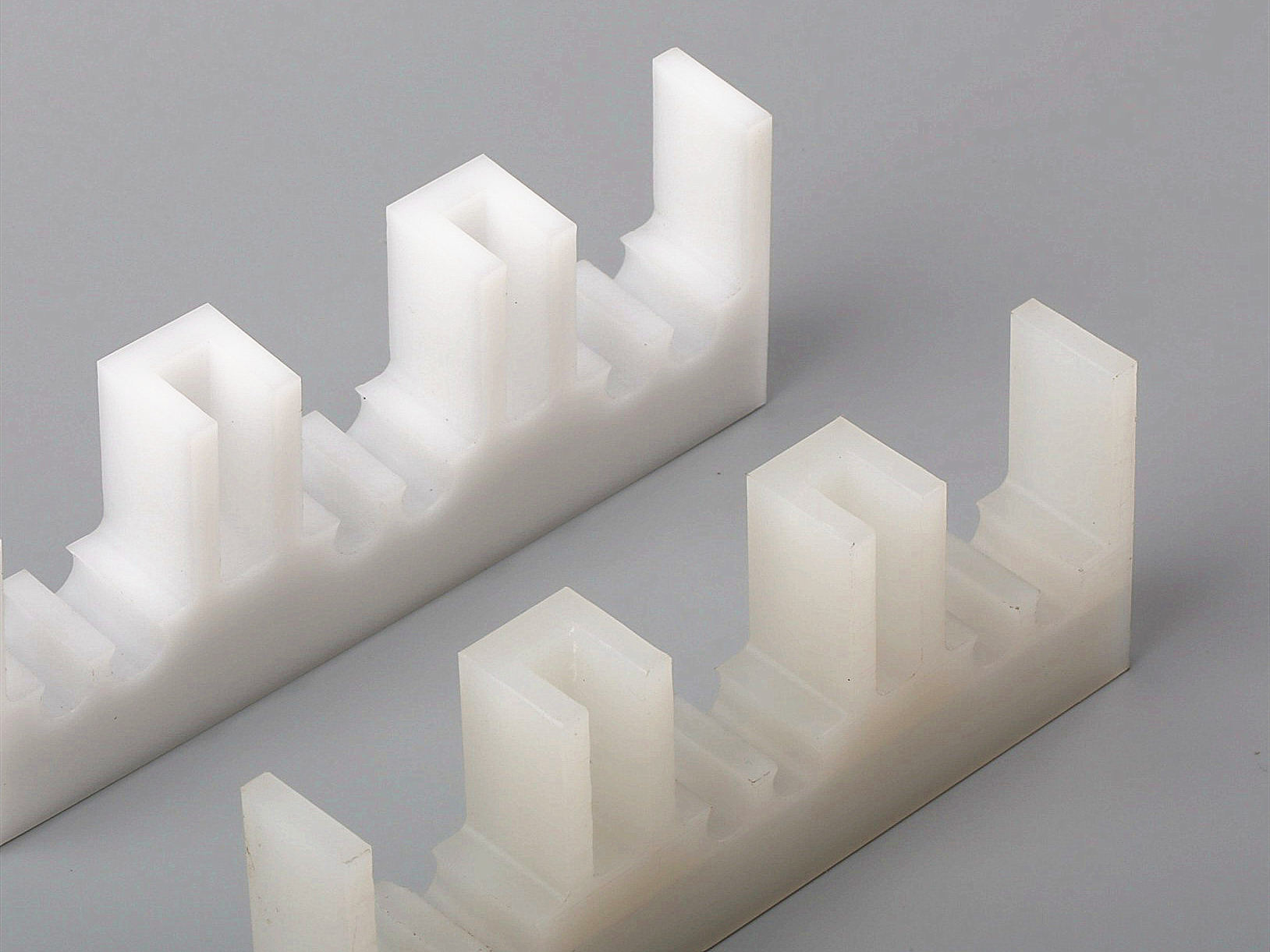

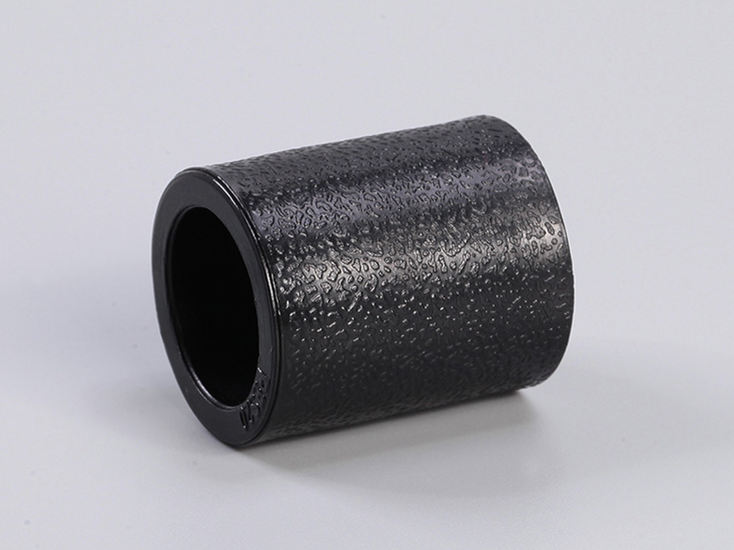

Inserts can be metal, another plastic, ceramic or just about any substance that can withstand the plastic injection molding process.

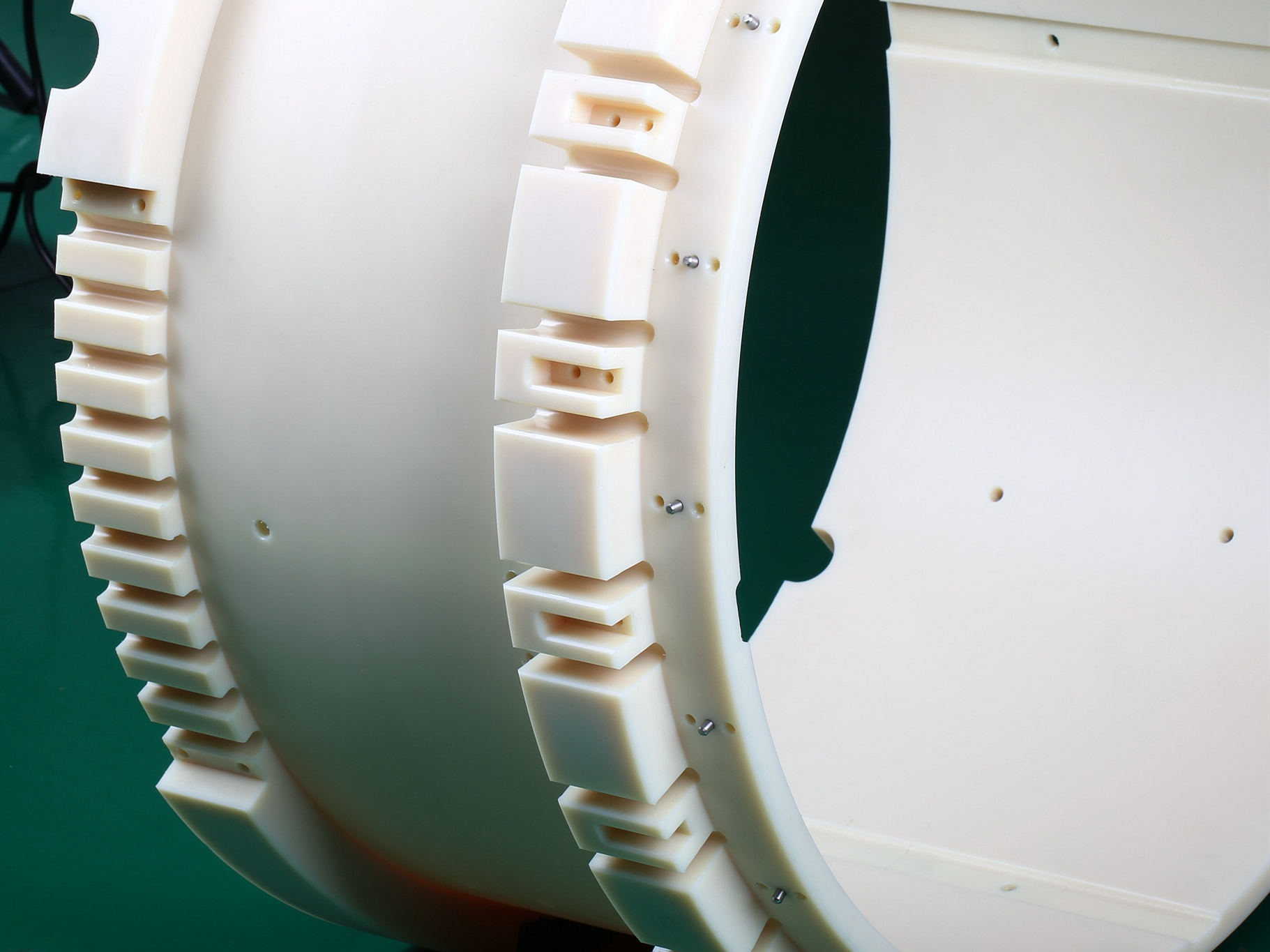

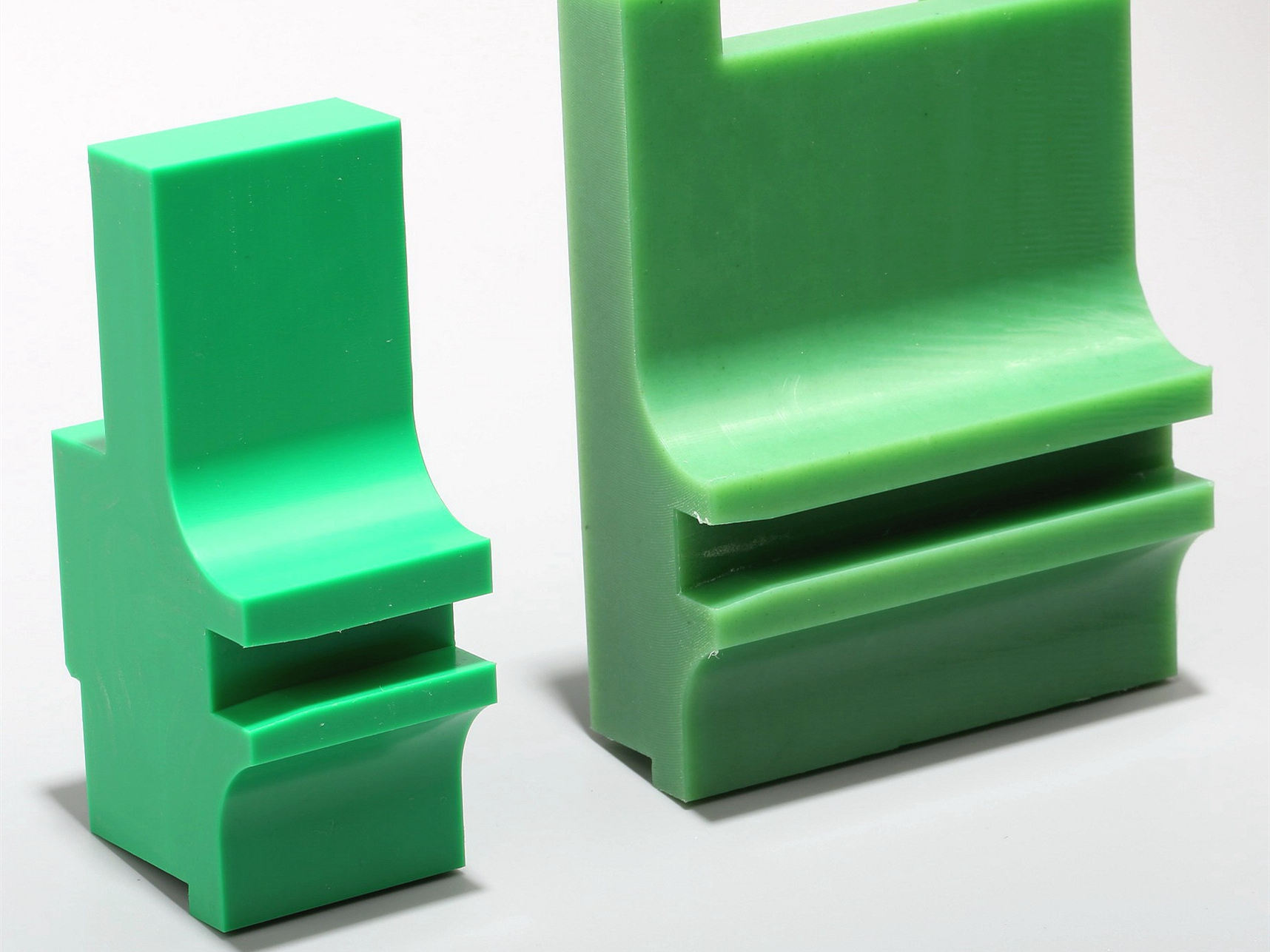

Depending on the size, shape & geometry of the part, a multi-cavity mold may be manufactured to increase production.

Secondary, post-molding operations are sometimes necessary to complete the assembly.

Which molding service suits you?

Features of Insert Molding

Advantages

Drawbacks

Insert Molding Processes

The overmolding process is utilized for a number of reasons that vary according to the specifics of the particular project. Common materials include toothbrushes, tool handgrips (e.g. cordless drills and screw drivers), and personal care products (e.g. shampoo bottles and shaving razors).

Here are some examples of typical overmolding applications:

Encapsulation

Placing threaded inserts into molded parts and encapsulating wire plug connections on electrical cords.

In-mold decorating (IMD)

Decorating injection molded plastic parts or components during the plastic injection molding cycle.

In-mold labeling (IML)

Labeling injection molded plastic parts or components during the plastic injection molding cycle.

Available Materials

Available Finishes

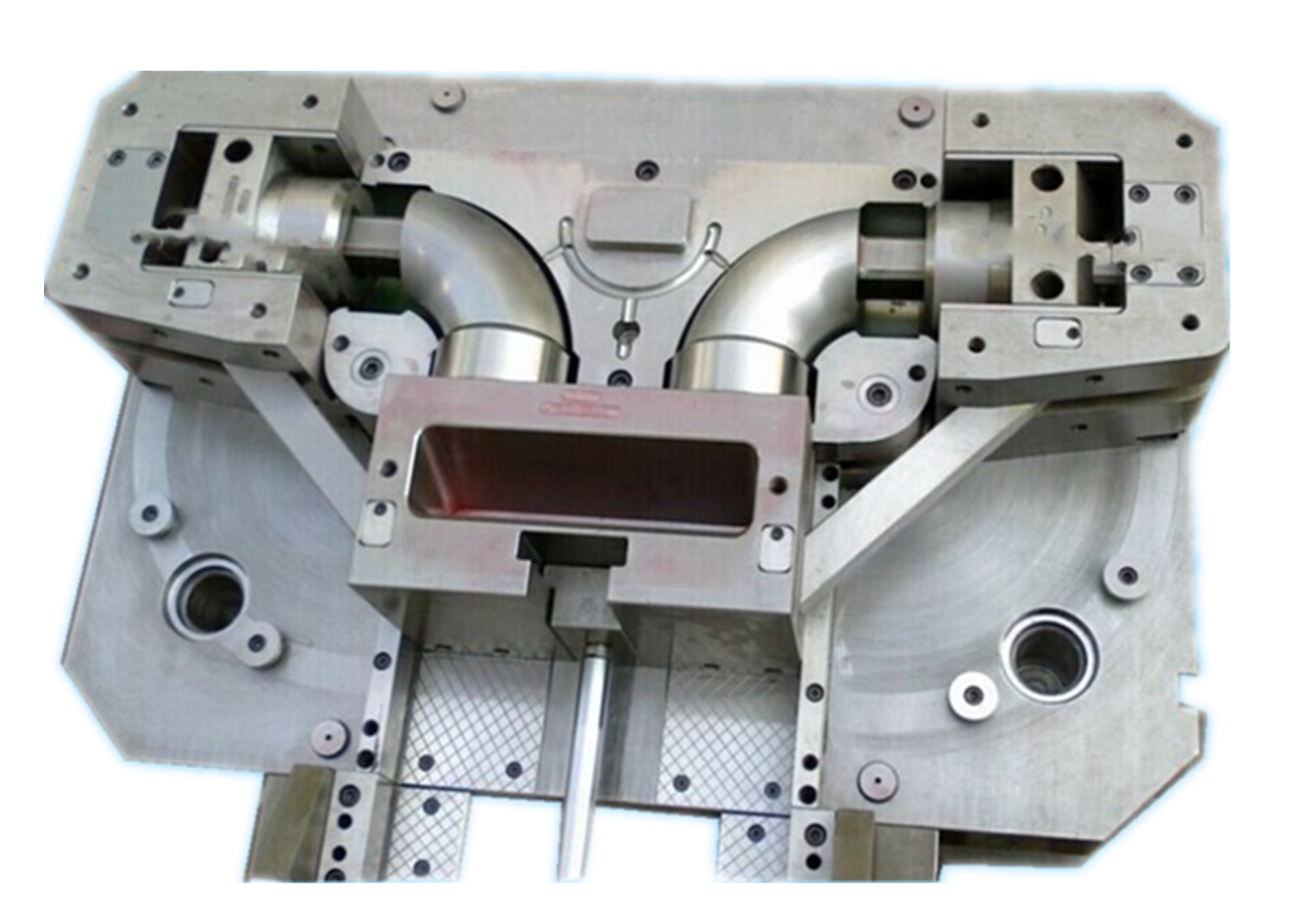

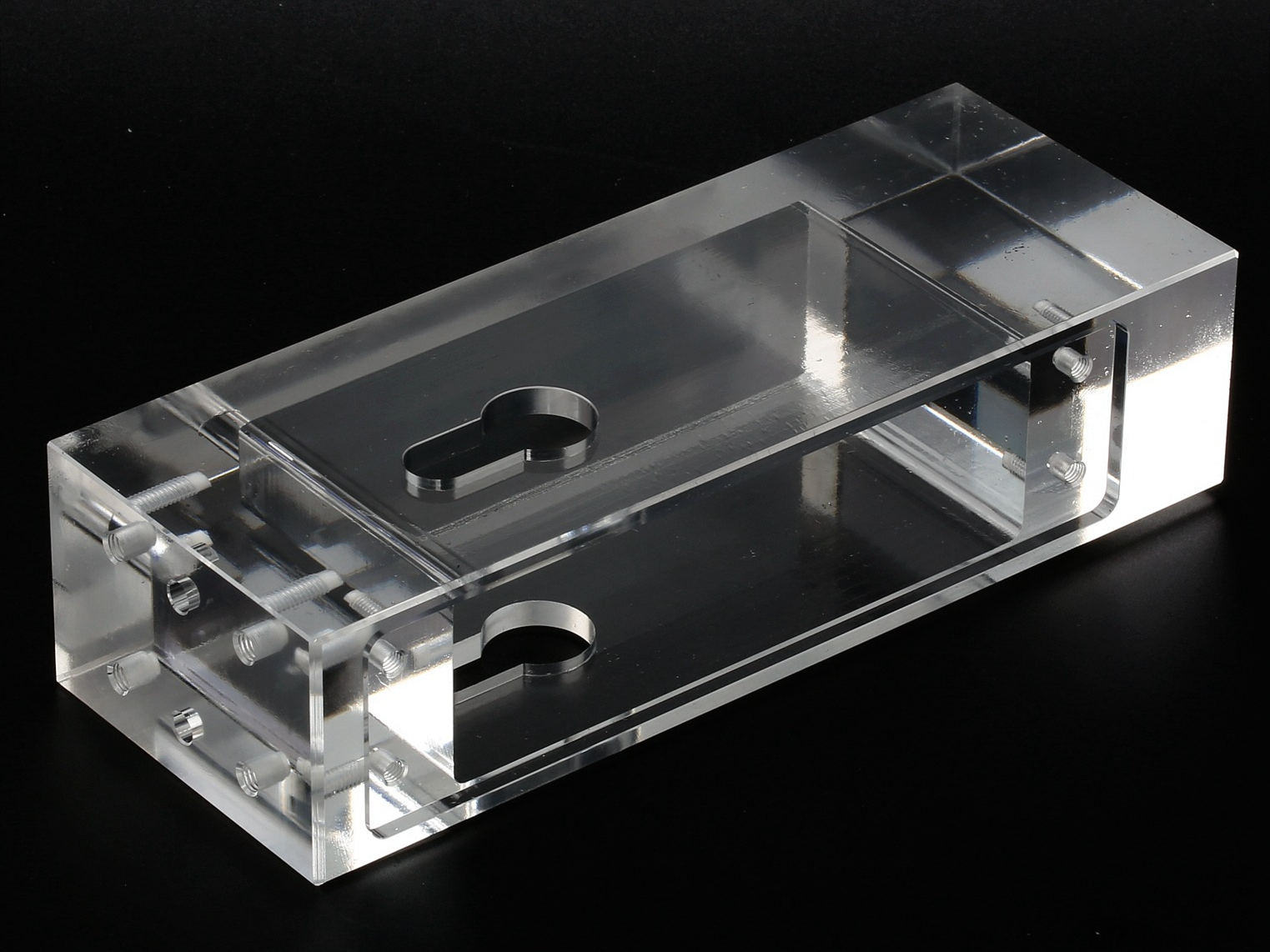

For rapid design molds, customers can receive T1 samples off a steel tool in as fast as 10 business days. Customers own the core and cavity inserts and we use factory-owned, interchangeable mold base inserts. Aluminum, S50C, P20, and NAK80 tool inserts are available as well as the Master Unit Die (MUD) quick-change system. Side actions are created with hand pick out inserts.

For production tooling, we produce stand-alone tools, ultimately owned by the customer. P20, H13, S7, NAK80, and SS420 insert steel is available as well as family & multi-cavity tools.

We will polish the mold to make the injected parts smooth enough, without obvious tooling marks.

- Sandblasting

- Surface Texturing

- DonŌĆÖt see the finish you need? Submit an RFQ with ‘Suggest’ option, or make a note with your special request, weŌĆÖll look into a finishing process for you.

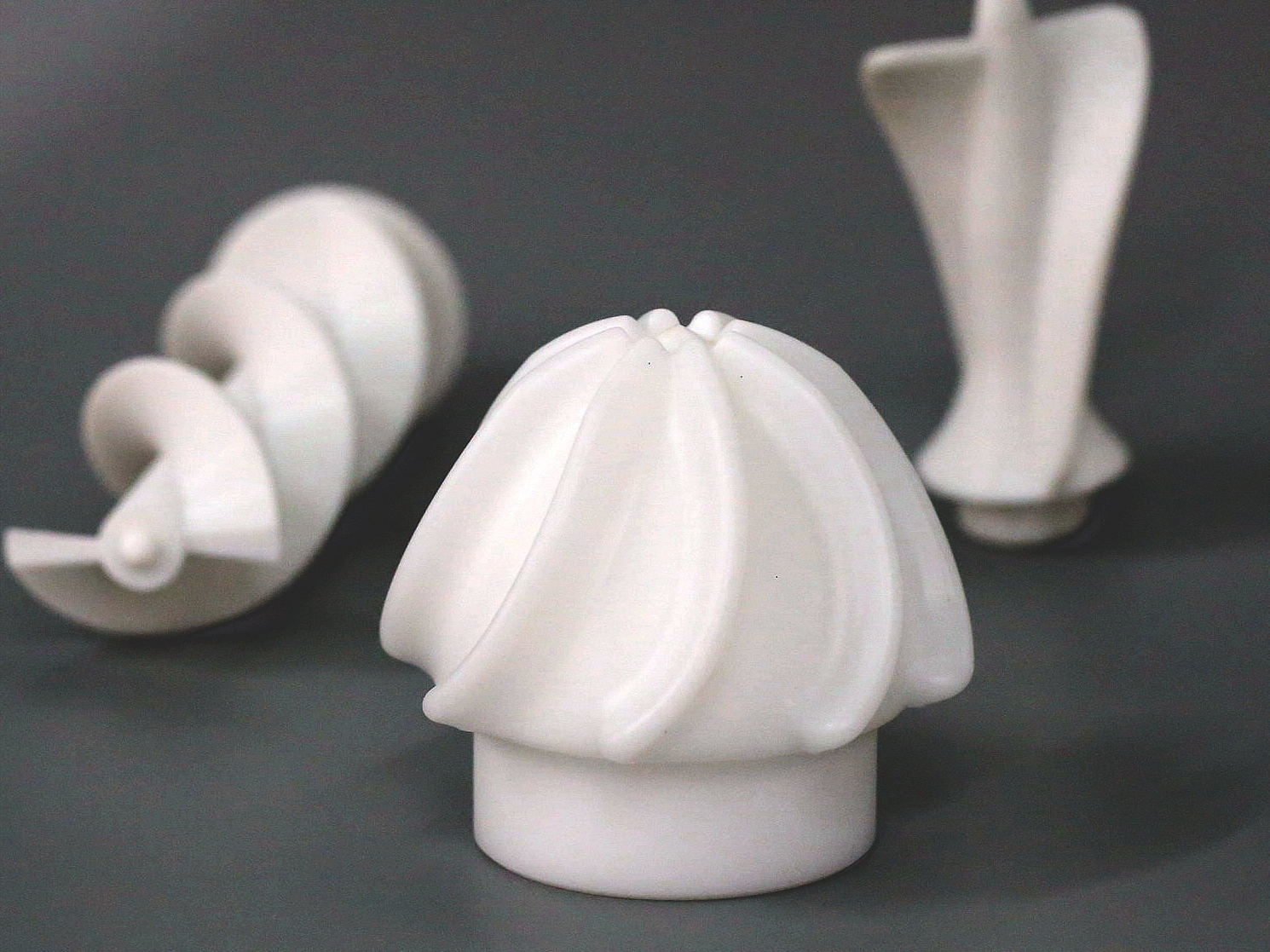

Insert Molding Applications

Small Batch Production

CNC machining can be applied to make high-quality tools from aluminum 7075-T6 for injection molding, the lifespan, depending on geometry of the design, lasts 1,000-5,000 parts.

Mass Production

Injection molding is the best choice for mass production the end products can be made using the exact material that will eventually be produced before the mass production.

Industries with Insert Molding

Resources for Insert Molding