Color Jet Printing (CJP)

3D print vibrant full-color prototypes and visual display models in as fast as 2 days.

Make full-color sandstone parts starting at only $20!

Overview: How Color Jet Printing works?

The Basics Of Color Jet Printing

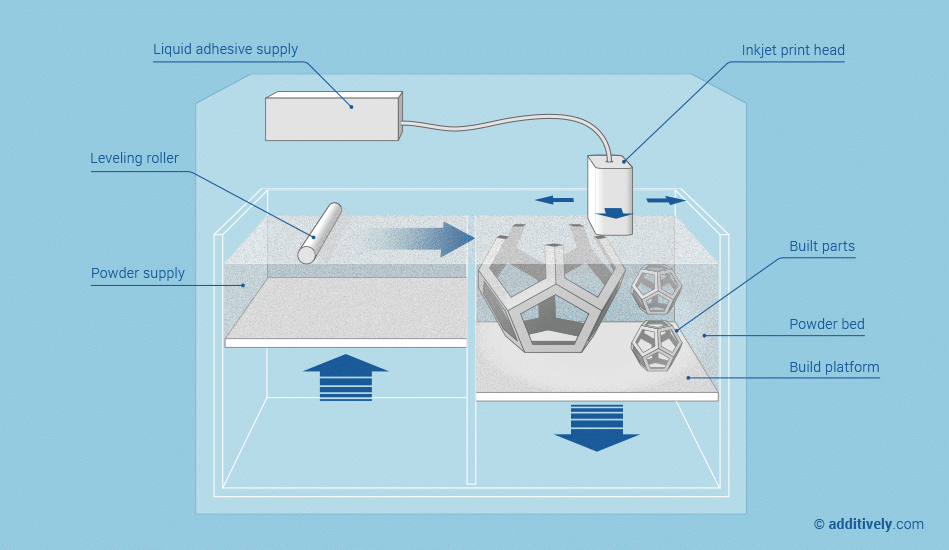

ColorJet Printing (CJP) is an additive manufacturing technology which involves two major components ŌĆō core and binder. The CoreŌäó material is spread in thin layers over the build platform with a roller.

After each layer is spread, color binder is selectively jetted from inkjet print heads over the core layer, which causes the core to solidify. The build platform lowers with every subsequent layer which is spread and printed, resulting in a full-color three-dimensional model.

Objects printed in full-color sandstone can withstand temperatures of up to 60┬░C (140┬░F) – beyond that the objectŌĆÖs properties can be significantly altered. Full-color sandstone objects are also somewhat fragile (comparable to a porcelaine), so it is important to handle them with caution.

The prints have a gritty surface and are relatively porous. It is thus important to avoid direct contact with water as it could result in discoloration or running of the colors.

Benefits Of Color Jet Printing

Full-color sandstone is one of the only 2 materials(the other is Polyjet Fullcolor Polymer) which can 3D print in full color. This makes it the perfect material for figurines, avatars, 3D-scans, or anything that require full color, it’s especially ideal for the following purposes:

- Full-color concept models

- Architectural models

- Demonstration models

- Highly complex geometries

- Quick production times

CJP vs Polyjet

Features of Color Jet Printing

Advantages

Drawbacks

Color Jet Printing Processes

– Printers: Projet CJP 660 Pro – Maximal build volume: 254 x 381 x 203 mm – Minimum feature size: 0.5 mm – Minimum layer thickness: 0.1 mm – Typical surface finish: 50 microns RA – Accuracy: (+/- 0.4-0.6%) Important decision on design is the orientation and support structures. This depends on: – Geometry, mainly inclination to reduce layer lines. – Areas that need great smoothness or post-processingPrinters & Parameters

Restrictions

Pre-build planning

Available Materials

Available Finishes

The raw finish option with the quickest turnaround.

The object is only cleaned of excess powder. This finishing leaves a grainy, rough surface.

The object is coated with a layer of varnish. This increases its resistance to humidity, water, and tumblings. This option leaves a matte finish.

Color Jet Printing Applications

With CJP, the prototype can be made using realistic full-colored material with great details. Fast turnaround makes it a good choice for concept models.Concept models

The versatility and support-less method of CJP let architectural models come out vividly.models

CJP can be applied to make high-quality complex full-colored demonstrative models with quick turnaround time.Complex Geometries

Industries with Color Jet Printing

Resources for Color Jet Printing