The NOVOPLASM consortium has announced it is the “first in the world” to develop cold plasma technology for the treatment of infected burns and the wound healing of skin grafts.

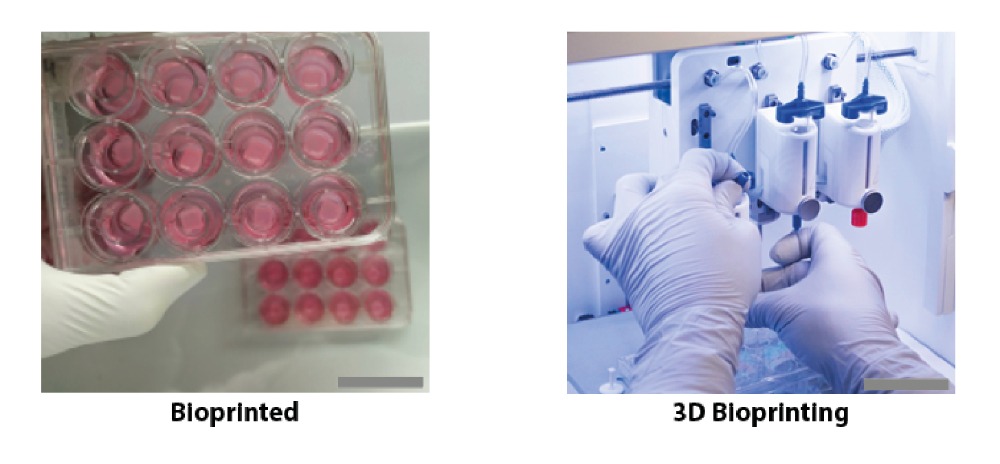

Regenerative medicine firm CTIBIOTECH, the French Armed Forces Biomedical Research Institute, École Polytechnique and Institut Pasteur make up the consortium, which is leveraging an immunized human skin model produced by 3D bioprinting to aid the development of the cold plasma treatment.

CTIBIOTECH claims to be the first in the world to 3D bioprint complete immunized human skin, called CTISkin, and is providing hundreds of models to the consortium to enable it to validate its cold plasma technology.

“Regenerative medicine is the future of healthcare,” said Professor Colin McGuckin, President and Chief Scientific Officer of CTIBIOTECH. “At CTIBIOTECH we advance these models to help personalized medicine and to support hospitals in the short term, not just the future. NOVOPLASM uses our models to accelerate new devices to protect human health.”

3D printing skin

CTIBIOTECH has been pioneering the production of 3D bioprinted functional human tissue for some time, having previously worked with BASF’s Care Creations department to conduct research into 3D tissue models of human sebaceous (skin) glands, and with Swedish bioprinter manufacturer CELLINK to investigate new therapies for patients with cancer.

3D bioprinted skin models have received increasing interest and development in recent years due to their uses for disease modeling, testing the efficacy of new treatments, and providing an alternative to animal testing.

Earlier this year, a research team from Pohang University of Science and Technology and Pusan National University 3D printed an in vitro artificial skin model to better observe skin diseases suffered by diabetic patients, while Pennsylvania State University researchers developed a 3D bioprinting process capable of printing hard and soft tissue simultaneously to repair skin and bone injuries.

3D bioprinting has previously been deployed to help heal burn wounds, with researchers from the University of Toronto and Sunnybrook Health Sciences Centre developing a handheld bioprinter that can print sheets of “skin”. The deposited bioink sheets cover the wound and help to accelerate the skin’s healing process, and could potentially be seen within a clinical setting in the next few years.

The NOVOPLASM program

Manufacturing on Demand

According to the World Health Organization, nearly 30,000 people suffer burns that require medical attention every day, totaling up to 11 million patients per year across the globe. The fourth most common cause of injury worldwide, burns are considered a major public health issue and one the NOVOPLASM project is looking to address.

CTIBIOTECH’s 3D bioprinting technologies enable scientists and clinicians to effectively and reproducibly evaluate the efficacy of new treatments and therapies on human tissue models. Using the company’s 3D bioprinted CTISkin model, the NOVOPLASM consortium was able to implement clinical strategies for skin healing and management of burn patients.

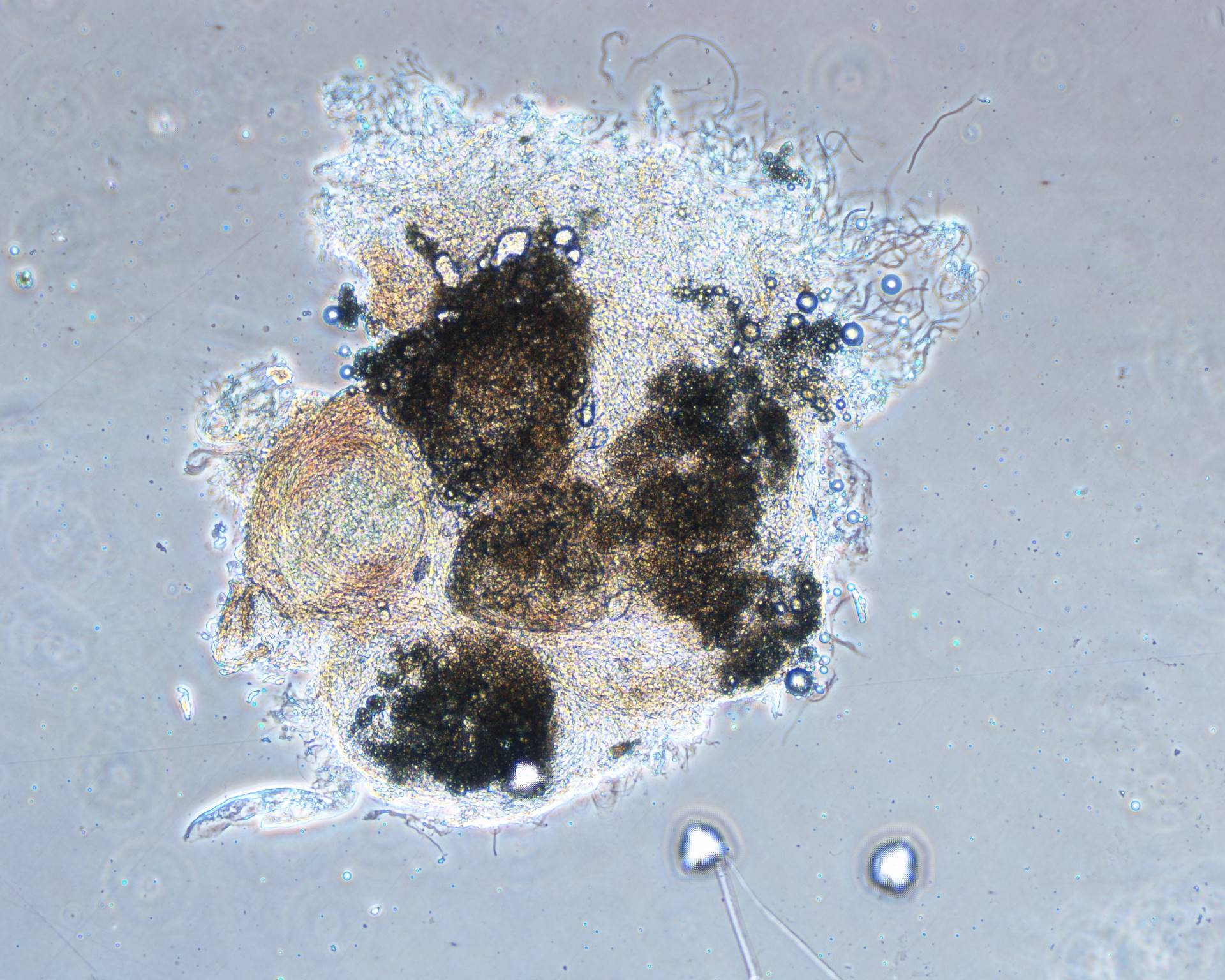

According to CTIBIOTECH, it is the first company in the world to produce immunized human skin – skin that contains immune cells – by 3D bioprinting. The NOVOPLASM consortium has leveraged hundreds of CTISkin models to validate its wound-healing cold plasma technology.

Cold plasma is a non-invasive, non-thermal and painless technology that works by energizing a gas with an electric current to cause the formation of nitrogen and reactive oxygen with pro-healing, reparative and bactericidal properties. These properties are particularly effective in improving the management of infected burns while also instigating the tissue repair process.

Research work carried out during the program has also shown the cold plasma technology promotes the formation of new blood vessels and mobilizes the immune cells present in the skin wound.

Once finalized and approved, the finished medical device will be suitable for use in hospital settings and specialized burn treatment centers. The NOVOPLASM project is supported by the French Ministry of the Armed Forces and has received funding from the Specific Support for Research and Innovation in Defense (ASTRID) program conducted with the French National Research Agency (ANR).

The NOVOPLASM project is presenting its work at the Defense Innovation Forum (FID) currently underway in Paris, France.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Hayley Everett

Leave A Comment