Williams Racing celebrated a new partnership with Nexa3D, which brings rapid polymer 3D printing to Formula One racing.

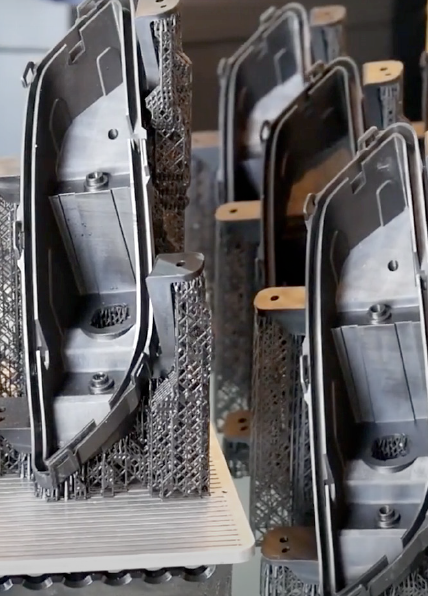

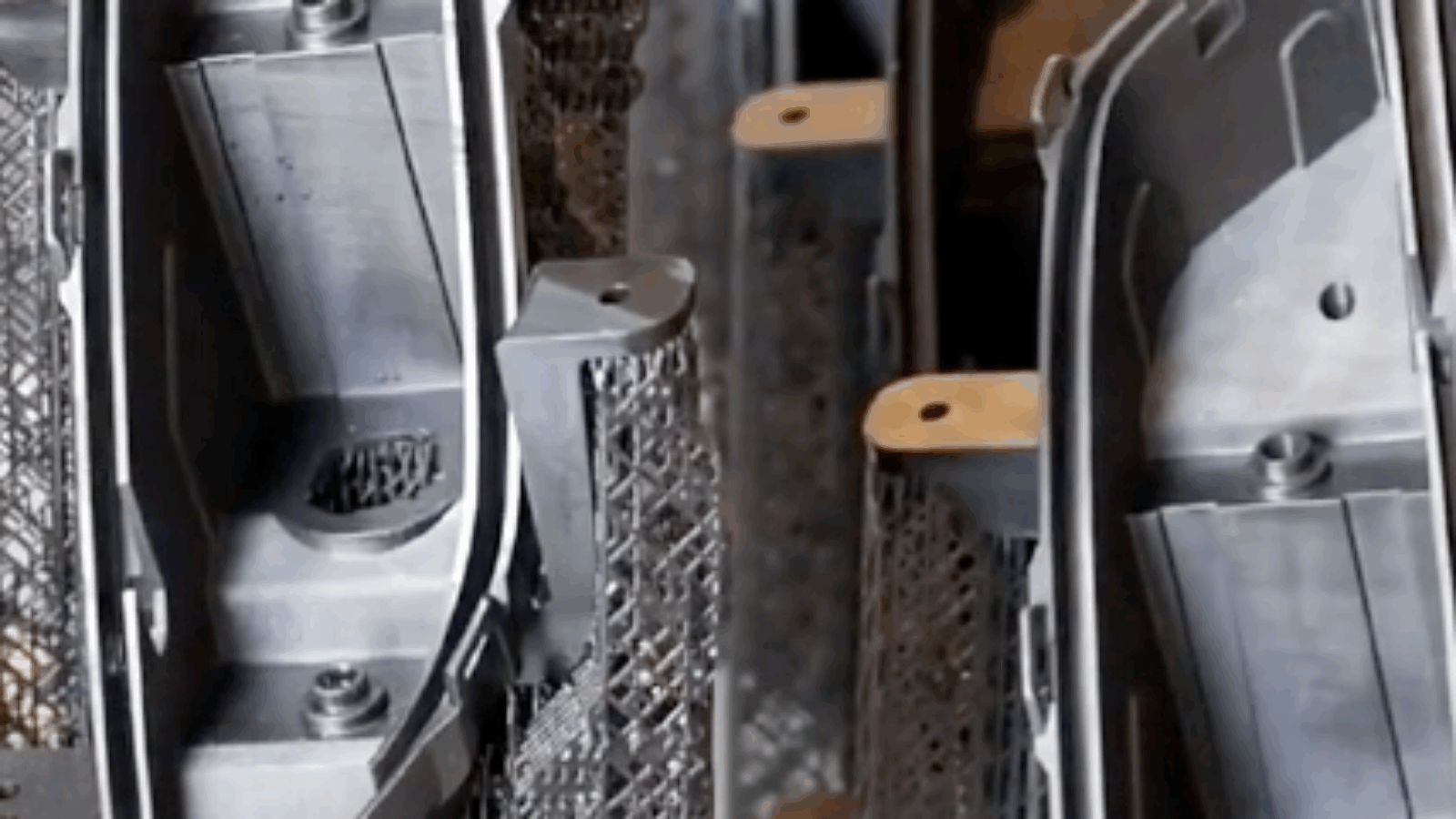

Beginning this month, Nexa3D’s NXE400 ultrafast photoplastic 3D printer will be available to manufacture functional wind tunnel parts for aero testing. The company’s NexaX software enables high-performance additive manufacturing processes using modern computation architecture to develop light-weight parts and to accelerate the file-to-part process. Speed of production lets Williams iterate and test parts faster, thus hopefully giving them an edge come racing time.

Manufacturing on Demand

With Nexa3D’s technology, Williams will be able to quickly design and manufacture complex, light weighted parts in minutes, compared to hours with traditional manufacturing, while minimizing material usage and waste. The NXE400 breaks printing speed barriers with its 20X productivity using Nexa’s Lubricant Sublayer Photo-curing (LSPc) technology and structured light matrix capable of reaching top speeds of 1Z centimeter per minute.

Al Peasland, Head of Technical and Innovation Partnerships at Williams Racing said, “We’re extremely excited to announce our partnership with Nexa3D and look forward to enhancing our additive manufacturing capabilities with their innovative high-speed printing technologies. Formula One is a challenging environment, that demands a continuous improvement philosophy in order to remain competitive. Our partnership will enable the team to continue to push boundaries in 3D printing, and present new opportunities for Nexa3D to further advance their revolutionary technology.”

“Our partnership with Williams Racing represents the fusion of top-tier engineering and race car performance,” said Avi Reichental co-founder, Chairman and CEO, Nexa3D. “With its ultrafast production cycles, the NXE400 represents the Formula One of additive manufacturing at scale. Few companies appreciate speed like Williams Racing and they represent the perfect partner for our polymer 3D printing technology.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Adam Strömbergsson

Leave A Comment