The cutting-edge 3D printing process, which creates solid objects from a digital model by layering up thin coatings of a chosen material, was initially viewed as a far-fetched, new-fangled experiment – but it has grown exponentially over the past few years, finding its niche in fields such as construction, the military and now hospitality.

Hotel

The future of responsible travel won’t be determined by paper straws or bamboo-fiber towels. Of course, rethinking what goes in the house is a good, even commendable start—but maybe we need to revisit how we build the house, too.

In 2015, the Philippines’ Lewis Grand Hotel unveiled the world’s first 3D printed accommodation, a 130sqm villa with two bedrooms, a fully functional living room, and a Jacuzzi. The structure was built using Audrey Rudenko’s concrete-printing method and took around 100 hours to complete.

Engineer Lewis Yakich said: “The 3D printer used on this project is still a work in progress, but it can easily be assembled or disassembled and then moved to another location for a future project in which it can print a large range of designs and design elements.”

In Barcelona, the Institute for Advanced Architecture of Catalonia has been employing armies of robots to print structures of any size. It won’t be long until hoteliers get in on the action – whether it’s 3D printing interiors and fixtures, or full-scale hotels. For chains, the possibility of replicating their offering quickly and precisely will hold great appeal.

Some brands are already rolling out modular hotels – in February, it was announced work had started on a pre-made 201-room Hampton by Hilton to be installed at Bristol Airport, with sections manufactured in China before being transported to the UK.

In the meantime, you may find 3D printers appearing in hotel business centers, allowing you to arrive at your next presentation with a freshly made 3D prototype.

Aviation

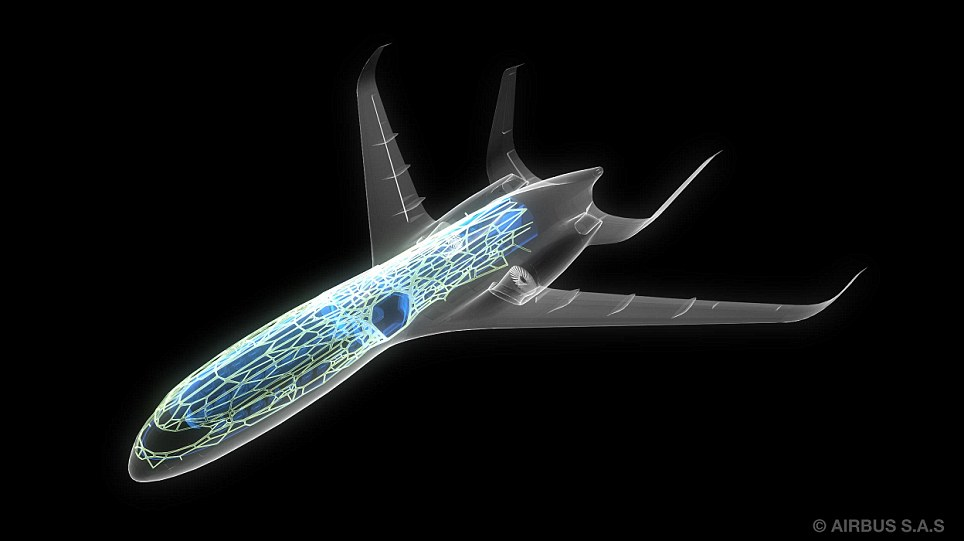

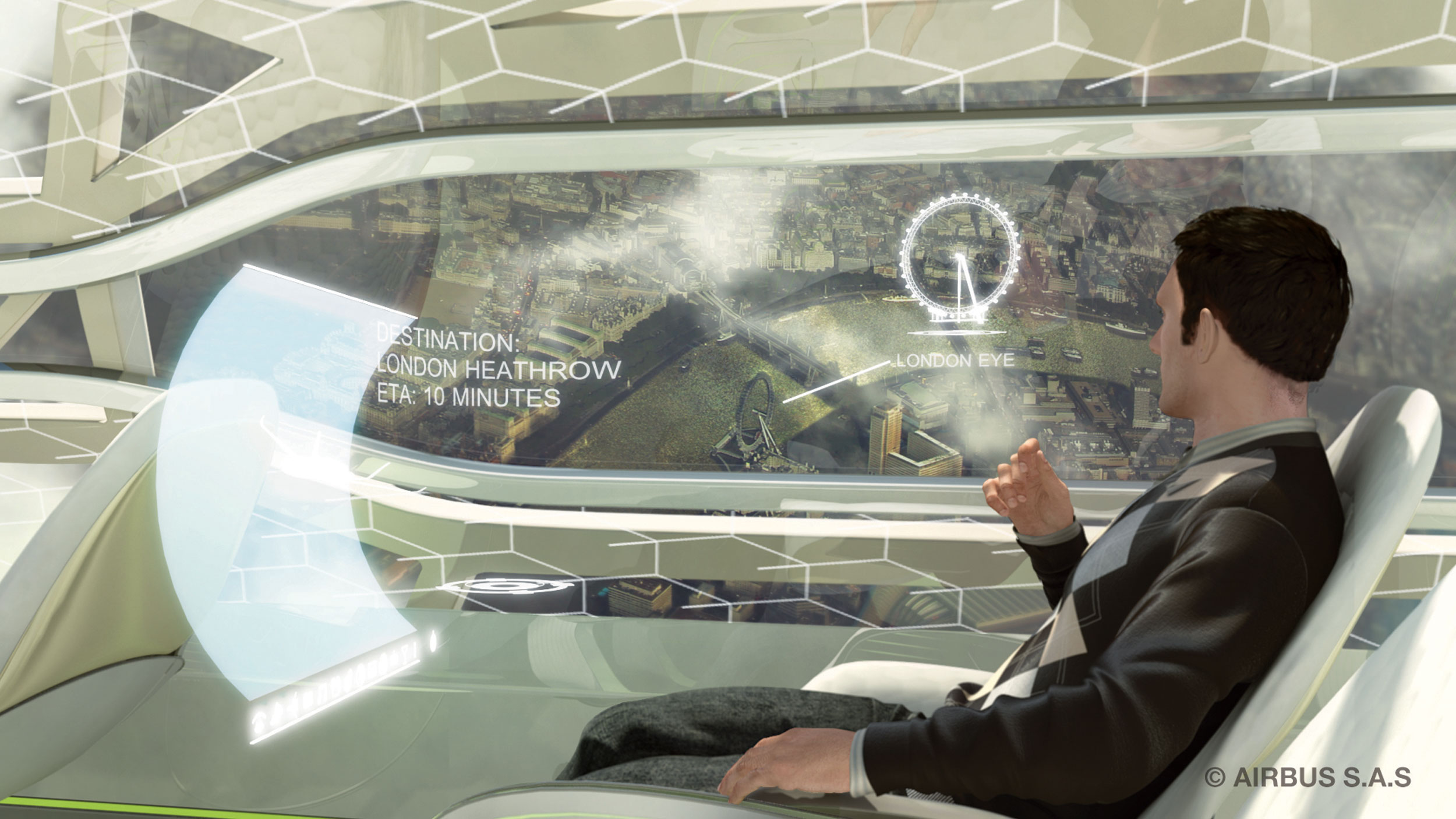

Airbus plans to assemble an entirely 3D printed aircraft by 2050. The 80m-long plane is said to have a transparent body to give passengers the feeling of floating among the clouds as they journey toward their destination.

In the meantime, the aircraft manufacturer has begun reducing the weight of their planes by adding 3D printed parts, the latest Airbus A350 XWB being the first to take the skies. International airlines are hopping on board the cost-effective trend as well with Air New Zealand and China Eastern Airlines taking baby steps toward sourcing more and more digitally printed aircraft components, from armrests and toilet seats to brackets and cocktail trays.

Tourist Attractions

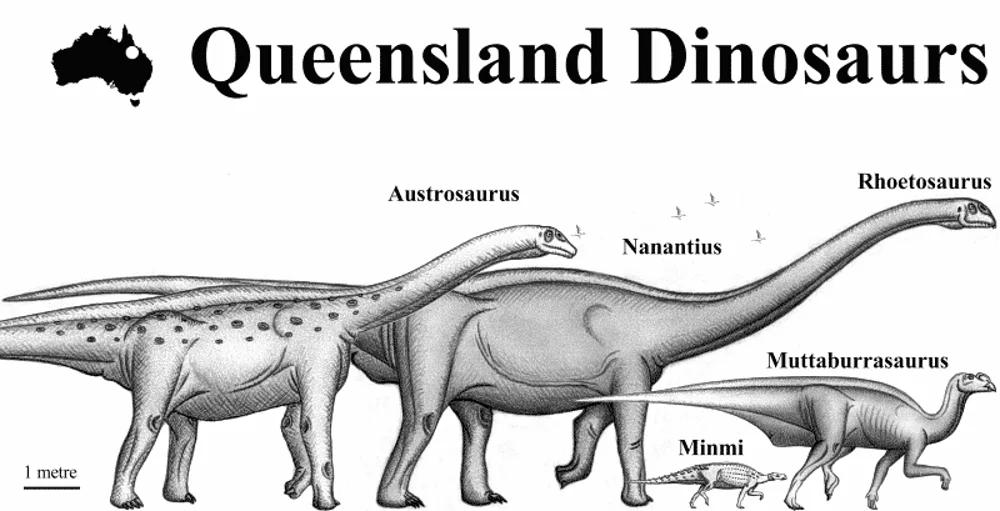

Visitors to the rural town of Roma in West Queensland, Australia, have the opportunity to get up and close to a dinosaur without fearing for the fate of the world. A $200,000 project for a massive 3D printed dinosaur became a new tourist attraction in 2017. The replica of the Rhoetosaurus of Roma will measure some 15 meters long and about 4 meters high. The giant herbivore lived about 170 million years ago and used its long neck, much like a giraffe, to reach high up vegetation. It is the oldest dinosaur skeleton found in Australia.

The process of building the dinosaur will require photographs of the skeleton to generate a 3D model. The model’s measurements would then be sent to a 3D printer, which would build the replica layer by layer. A CNC machine will also be used to cut larger parts from foam. The project is estimated to require two years for completion.

Souvenirs can be an important element of a tourist experience with most visitors bringing back mementos and souvenirs.

Leave A Comment