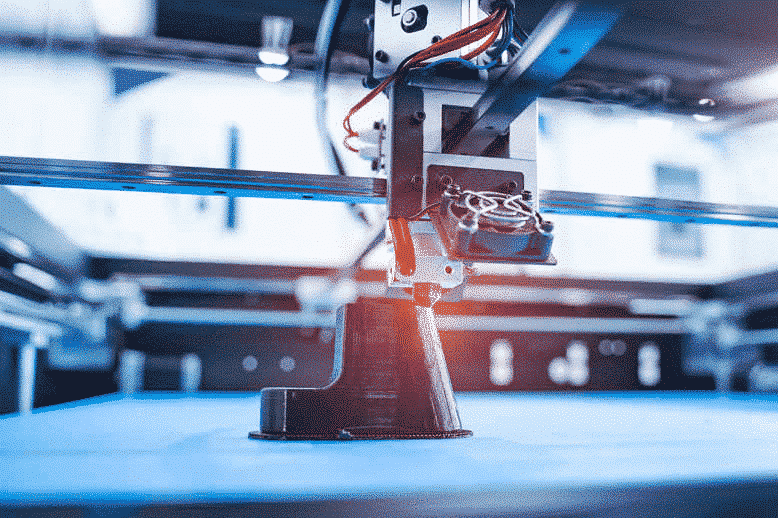

What’s 3D printing?

3D printing is a process which creates items from a 3D model. With a 3D printer and incorporating material layer by layers, like metals and plastics objects, may be made at low cost and quickly, in runs or as pieces. HP Multi Jet Fusion 3D technology gives quality, speed and strength through the process for a range of businesses and applications and empowers customers to make components with functional and physical properties.

How has 3D printing evolved through recent years?

In which technology will alter how businesses respond, design, create, distribute and fix everything we are on the cusp of the Industrial Revolution? The international demand for products and alternatives has led to a spike in demand for goods and components. Prices have been halved by innovations in the area while providing the performance. Since the 3D printing industry goes past prototyping, usage of the technology, especially in distribution chains, is becoming more and more widespread.

In 2018, HP established Metal Jet technology, the planet’s most innovative 3D printing technologies for its production of metallic components. It delivers components that are functional with up to 50x greater productivity compared to other 3D printing procedures, and at a lower price in comparison to binder jetting systems.

As we see clients scale through a growing ecosystem of partners for cooperation and creation, the options are increasing for a new age of manufacturing.

What are the trends in 3D printing?

Is that the effect of fabricating take hold around the health care, industrial and automotive industries, especially in the kind of production software. In the automobile industry, we have seen an increased emphasis on creating substances for automobile software as 3D printing gravitates from prototyping to production of goods and components. As new platforms like electric vehicles input production, HP Metal Jet is expected to be leveraged for software like the weighting of metallic components that were entirely safety-certified. 3D manufacturing enables the industry to make applications in ways which were impossible, together with the capacity to design components for versions or systems.

What technology have you noticed used with 3D printing?

One instance of 3D printing we have seen in the past couple of months is producers and 3D providers are coming together to help create programs that are vital to helping fight COVID-19. HP and its network of clients and partners are printing parts like ventilator valves, door handles and face mask adjusters for health care providers and hospitals around the globe.

Beyond the way 3D is encouraging the present scenario at hand, we have seen myriad ways that the technology was utilized — everything from customised prosthetic limbs, to elements which are used in automobiles, to invisible braces assisting individuals to attain their preferred smile.

With industries facing increased customer centricity, how can 3D printing help to drive customer centricity?

Among the advantages of 3D printing is the ability to customise components and goods entirely. This might be in the shape of design taste, or it might serve a function such as enhancing usability or the fit of a product. By way of instance, 3D printing shortens the manufacturing time from weeks to days and makes it effortless to personalize limbs, and it may deliver individualized and custom-fitted apparel, such as insoles, through lively gait evaluation scanning and technology.

How does 3D printing make production more flexible?

By enabling consumers to dictate needs, 3D printing gives itself to supply chain freedom, flexibility and adaptability. Companies need to forecast consumer demand by betting 3D printing ensures flexibility since they can publish what they require.

3D printing also enables producers to make prototypes efficiently, since they may publish a brand new model via a tweak on the program. Thus, saving money and time rather when they making moulds every time.

3D printing also allows generating large volume in a brief time. HP client SmileDirectClub utilizes Multi Jet Fusion 3D printing alternatives to generate more than moulds daily and expects to print almost 20 million mouth moulds during the subsequent 12 months.

In 2018, over 10 million components were created using HP Multi Jet Fusion technologies.

How does 3D printing benefit the production market?

3D printing completely reinvents how items are conceived, made, made and distributed lowering manufacturing and development expenses, immensely simplifying logistics, and lowering carbon footprint. It holds great potential and we’re starting to see a rise in the number of businesses that turn to the kind of manufacturing produce products and to be able to remain competitive.

3D printing is going to probably be the catalyst for major changes within the manufacturing industry that is international, and leaders will likely be characterized by their capacity to exploit its power that is disruptive. In a digital future, the creation of merchandise will be pushed enabling goods to be mass-customized and democratizing production. Since the line between fact and ideas erodes, by procedures, designers are free to produce new classes of merchandise. And producers restricted to international factories will shorten supply chains anyplace.

What are the challenges of 3D printing?

The barrier is the change of mindset. It’s essential to consider designing in the very first phases of product development for 3D, to consider the implications of growth in supply chains could be optimized and staged to full-scale manufacturing. You will find a profound sense of hurdles and limitations. There is a procedure which has to occur — the bulk those constraints use. The design possibilities are infinite. And some skills have to be developed to manage these changes. For engineers components of the plan, the procedure is going to be introduced in their functions where they need to learn the mechanisms of 3D printing to become specialists in the procedures and best encourage purposes.

What software of 3D printing have you ever noticed within the business?

3D printing is used in an assortment of industries such as health care, manufacturing, automotive and consumer products. Together with the efforts, I have also seen some programs in the industrial sector. 3D printing has been used by car manufacturers to generate security goggles and gear sticks, fashion designers are currently creating 3D printed shoes and handbags and habit foot insoles are being printed by organizations. The possibilities are endless and I am excited about seeing what comes from this sector during the upcoming few decades.

The job being done by Jaguar Land Rover as they progress EV growth, or Vestas VBIC, the biggest supplier of wind turbines on earth, are important examples of the way 3D printing is allowing businesses to move easily from prototyping to manufacturing, with unbelievable flexibility to create progress in near real-time.