Voxelab, a subsidiary of Frashforge, is launching its latest high-temperature, direct driver 3D printer, the Aquila D1 – which includes an upgraded direct drive extruder design, 100mm/s printing speed, and an X- and Y-axis linear guide.

Generally speaking, the faster the printing speed, the more likely it is for adhesion problems to occur between layers. The faster the base speed, the easier it is for the nozzle to get clogged, due to the increase in the amount of material being extruded at the same time.

The Aquila D1 extruder has been upgraded with a high-temperature nozzle, of up to 300°C, to ensure that the printing material can fully melt, to produce sufficient adhesion – solving the problem of the non-adhesive bottom layer. The printer is also equipped with a high-speed fan to quickly cool down parts and prepare for the next layer of printing. The high-temperature nozzle also greatly enhances the choice of materials – to include materials such as ABS, PETG, and TPU.

Manufacturing on Demand

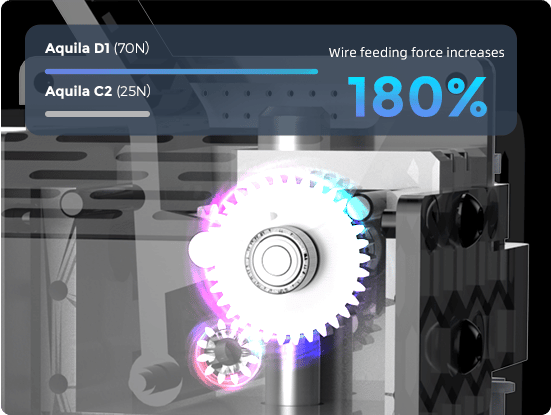

Voxelab has added a powerful component to the entire extrusion system, reaching a filament feeding force of 70 Newton – an increase of up to 150%. This ensures smooth extrusion, even during high-speed printing, and avoids the potential consequences of clogging (damage to the machine interior and reduced nozzle life, for example).

Aquila D1’s maximum printing speed is 180mm/s, with an average speed of 100mm/s, which is almost 200% faster than its precursor. When building the same models on Aquila series printers, Aquila D1’s printing time decreased print time by 60%, overall, without a compromise on quality.

The Aquila D1 adopts a dual linear guide to achieve a more stable printing performance. The printer’s X- and Y-axis use linear guide rails to yield smoother motions – helping reduce the surface texture caused by machine shaking, and allowing for higher precision and printing with finer details.

The Aquila D1 is now available for pre-order, for $400.

You might also like:

Visitech introduces LRS-8KA, the first 8K DLP UV projector: Visitech has developed its sixth-generation LED illumination solution, providing superior power output for maximum printing speed. The sophisticated driver design maintains constant power dosing throughout the operation. A complete, liquid-cooled thermal solution further provides the necessary heat management of critical components while mitigating the incursion of dust particles into the optical system. In addition, the compact, modular design is designed for easy replacement, simplifying maintenance routines in industrial settings.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment