Biotechnology firm United Therapeutics and Israeli bioprinting firm CollPlant have broadened their partnership to enter into the serial manufacturing of 3D printed kidneys.

The new agreement, which builds on the companies’ initial deal in 2018, will combine CollPlant’s novel technologies with United Therapeutics’ manufacturing capacity to put 3D printed organs into production. As part of the contract, United Therapeutics has also paid $3 million to exclusively license CollPlant’s collagen and bio-ink products for future projects.

It’s hoped by both parties, that their strengthened partnership will reduce global waiting times for organ transplants, potentially saving millions of lives around the world.

“Organ shortages are an unmet global health need,” said Yehiel Tal, CEO of CollPlant. “By partnering with United Therapeutics for the past couple of years, we have made significant progress with this pivotal organ manufacturing initiative.”

CollPlant’s 3D bioprinting technologies

Founded in 2004, CollPlant is a regenerative and aesthetic medicine company that develops technologies and products for tissue regeneration and organ manufacturing applications. The company leverages its proprietary plant-based technology to mass produce recombinant Type I collagen, which is identical to that made in the human body.

In May 2017, CollPlant set up a division that was dedicated to turning its collagen into a unique bio-ink formula. The firm successfully developed a bio-ink, that was cured once exposed to UV light, turning it into a cell-based hydrogel that’s compatible with 3D printing. In the years since the company developed its novel formula, it has received significant backing from investors to expand on its applications.

The firm received an initial $5 million in funding from a U.S. investor in September 2017, and later gained another $5.5 million from a group of investors earlier this year. Utilizing its newly-raised resources, CollPlant has continually developed its technology, with the aim of deploying it within end-use applications. In August 2019, the firm took its first steps towards serial production, creating a series of prototype 3D printed breast implants.

More recently, the company has sought to collaborate with larger 3D printing companies, with the aim of more effectively scaling the use of its novel collagen-based bio-ink. Having initially signed deals with 3D Systems and United Therapeutics to create additive lungs and scaffolds, CollPlant is now building on the latter, as it aims to enter serial production.

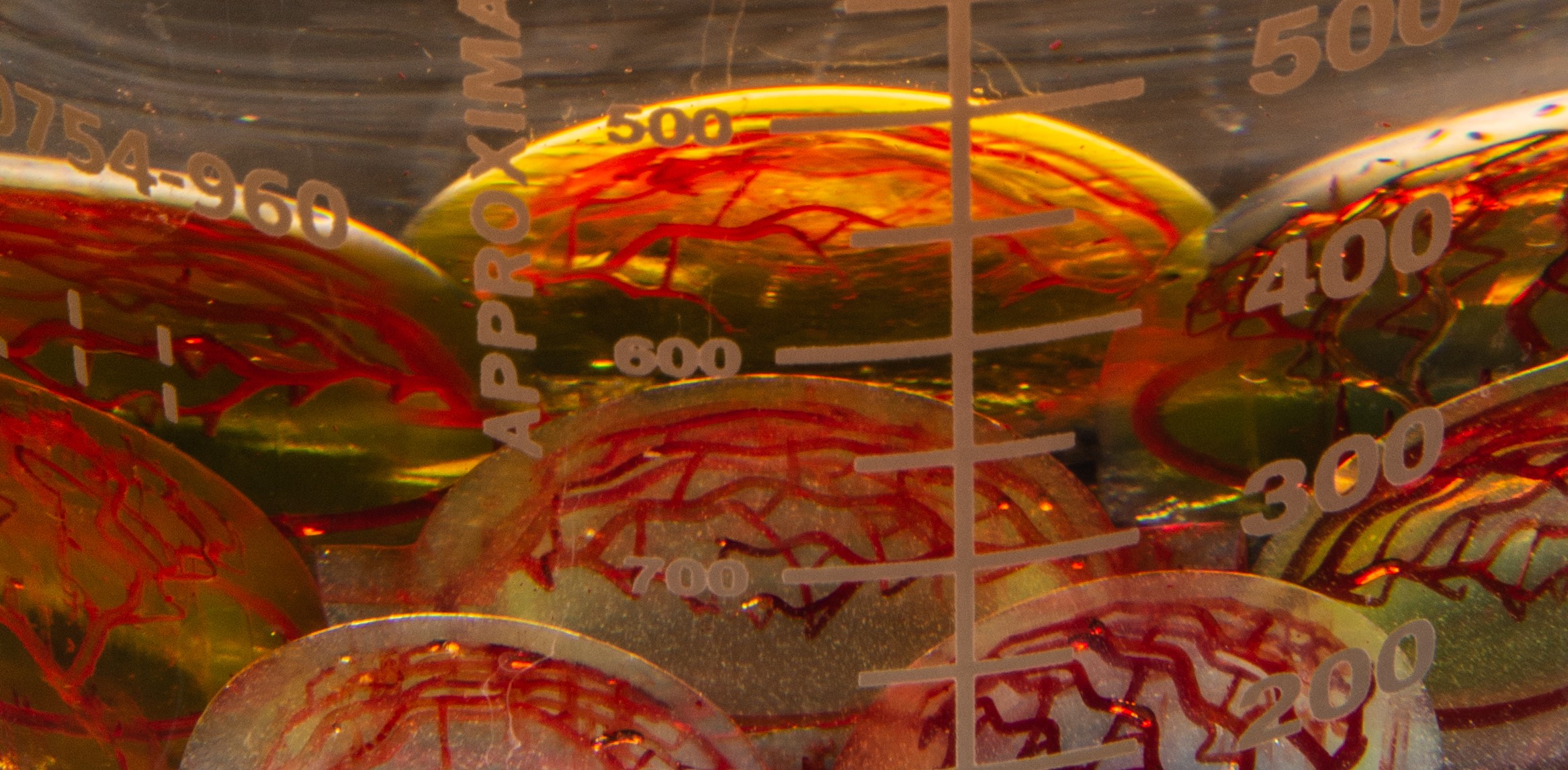

CollPlant previously worked with 3D Systems to bioprint a number of tissue scaffolds (pictured). Photo via CollPlant.

CollPlant previously worked with 3D Systems to bioprint a number of tissue scaffolds (pictured). Photo via CollPlant.

United Therapeutics’ 3D printed kidney factory

According to the U.S. Health Resources and Services Administration (HRSA), over 109,000 Americans are currently on the national transplant waiting list, with 92,000 waiting for potentially life saving kidney donors. As a result, 3D bioprinted alternatives remain a critical area of development, and the news that the additive organs will be going into production, could represent a major step in their wider adoption.

The latest deal between United Therapeutics and CollPlant builds on the collaboration that the firms established in 2018. CollPlant initially agreed to supply its novel bio-ink as well as providing technical support to United Therapeutics. Now the companies are working more closely together, as they seek to scale their overall bioprinting production capacity, and establish a US facility for creating additive organs.

Manufacturing on Demand

Although the partnership is currently focused on transplantable bioprinted lungs, United Therapeutics also has the opportunity to explore the use of CollPlant’s bio-ink technology for up to three more organs. If the companies do go ahead with developing further additive implants, CollPlant will be due up to $15 million dollars in pre-agreed milestone payments.

Describing United Therapeutics as a “pioneer” in the emerging field of organ manufacturing, Tal said that CollPlant was “honored to be part” of the new deal, and described it as a “vital building block in regenerative medicine.”

As part of their preparation for entering serial production, the companies have recently turned a former tobacco production complex into a modern 3D bioprinting factory. The irony of reshaping a facility with negative health repercussions to one that was positive, wasn’t lost on Martine Rothblatt, CEO of United Therapeutics.

“We are excited to expand our collaboration with CollPlant’s extraordinary technology to transform the tobacco plant – one that is so associated with devastating diseases – into a collagen-expressing plant that will be essential to the production of an unlimited number of transplantable organs,” added Rothblatt.

A brief history 3D bioprinted organs

Although researchers have consistently experimented with bioprinted tissues, mass production has so far proved elusive. Consequently, many additive organs have been created on a miniature scale, and the technology is still thought to be years away from fruition.

Researchers from the University of Minnesota for instance, have developed a novel bio-ink, enabling them to 3D print a miniature functional beating human heart. The team’s new cell-laden biomaterial allowed the team to produce an aortic replica with more chambers, ventricles and a higher cell wall thickness than was previously possible.

A team of researchers from Tsinghua University have 3D bioprinted brain-like tissue structures capable of nurturing neural cells. Once integrated into a lab rat, the organ portion was able to form a complex neural circuit, that was capable of responding to external stimuli.

Earlier this year, scientists from Texas Tech University Health Sciences Center El Paso (TTUHSC El Paso) and The University of Texas at El Paso (UTEP) 3D printed artificial miniature hearts. The heart-tissue structures were sent to the International Space Station (ISS) to gain an insight into how microgravity affects the function of the human heart.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment