The application of 3D printing technology in shoe design, R&D, and casting production is quite mature. At present, UnionTech 3D printing technology is reshaping the entire shoe industry, and a new round of competitive advantage is formed quickly, efficiently, and personally.

3D printing technology can simplify the complex processing process, quickly produce products from the three-dimensional data. Compared with the traditional shoe-making process, 3D printing process is more intelligent and automated, which saves labor forces and brings some advantages like high efficiency, precision, flexibility, etc. With the gradual breakthrough in technology and materials, we will actively explore more possibilities at the application level as always.

Design

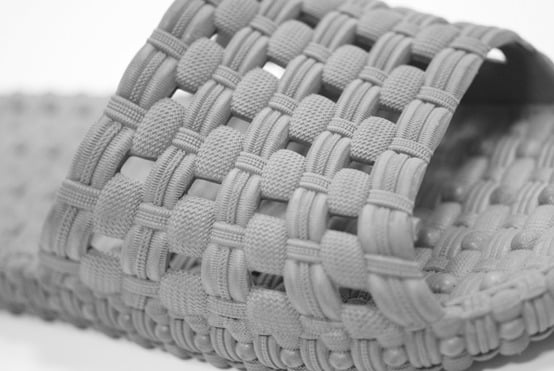

Design is the very first step in the birth of a pair of finished shoes. The aesthetics, comfort, and structure of the finished shoes are all pre-considered in design verification. 3D printing technology has a very significant advantage in the design process. It can overcome the difficulties like extremely complex structure, the hollow shape of the arbitrary curve and extremely complicated texture. 3D printing directly processes by the software, input into the 3D printers, and the sample is quickly obtained to get the actual product. It only takes a few hours for the input of a 3D image file to the output of the finished product, which greatly accelerates the speed of product innovation, effectively enhances the core competitiveness of the enterprise market, and realizes the personalized production of products.

Sampling

3D printing is mainly used for sampling of new products in the development and design stage, which refers to samples and prototypes. Sampling is to print out the two-dimensional or three-dimensional graphics designed with the computer to confirm whether the new product structure and the actual effect can meet the needs of the market or customers. After confirming the samples in the development and design stage, 3D printing equipment can also be used for the rapid production of sole molds.

Rapid Molding

3D printing technology is a very flexible and fast production method in IM EVA mold manufacturing. It can effectively reduce the cost of mold making and reduce waste, and it can also get products in a short time, achieving a multiplier effect.

Texture

The advantage of digital batch texture lies in:

- PersonalizationEnhance the aesthetic value of the parts, and can design and create without restriction. You can use highly aesthetic or functional textures and patterns to improve the design quality of customers and create unique or personalized works.

- Environmental protectionIn the contemporary manufacturing system, environmental protection is the primary consideration. This is also the industrial advantage of UnionTech 3D printing plus digital biting technology, and also the trend of future manufacturing development.