Sometimes 3D printers can get confused. They extrude too much or too little materials, or deposit materials in the wrong place. But what if this error can become a (popular) feature?

DefeXtiles, a textile similar to tulle, is developed by Jack Forman, a graduate student in the MIT Media Lab, by controlling common 3D printing defects (insufficient extrusion of polymer filaments).

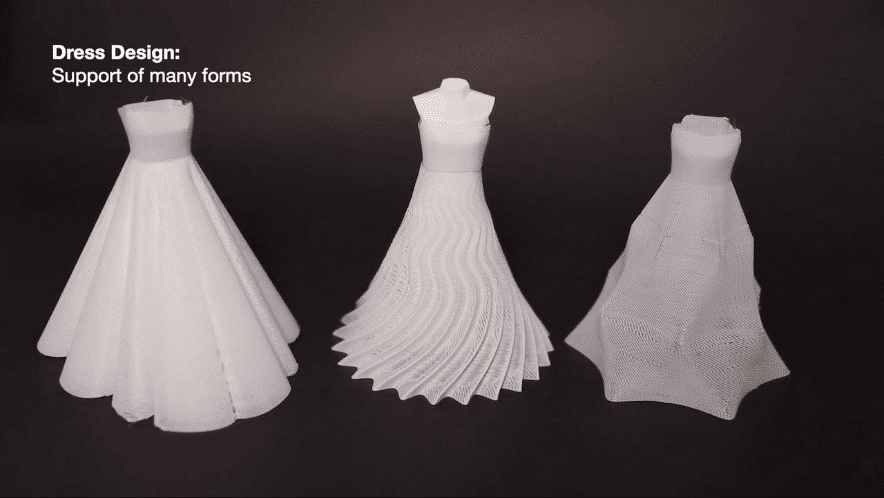

Forman used a standard inexpensive 3D printer to produce sheets and complex 3D geometric shapes with a woven structure based on a “spherical stretch” pattern created by under-extrusion. Forman printed these soft and thin sheets into interactive lampshades, full-size skirts, a roll of fabric large enough to stretch on baseball diamonds, and intricately patterned lace.

Forman worked with Hiroshi Ishii in the Tangible Media Research Group. He introduced and demonstrated the DefeXtiles research at the Computer Association User Interface Software and Technology Symposium on October 20. Forman said that this material may be immediately useful for prototyping and customization in clothing design, but future applications may also include 3D printed surgical mesh with adjustable mechanical properties.

“Overall, what excites me most about this work is how useful it is to many manufacturers,” Forman said. “Unlike previous work, the fact that there is no need to customize software or hardware-just use a relatively cheap $250 printer, which is the most common type of printer used-really makes this technology available to millions of people.”

Ishii said: “We believe that the materials of the future will be dynamic and calculable.” “We call them ‘radical atoms’. DefeXtiles is a good example of Radical Atoms (radical atoms), it is an A programmable substance that mimics the characteristics of existing materials and surpasses it. We can touch, feel, wear, and print them.”

Joining Forman and Ishii are Mustafa Doga Dogan, a graduate student in the Computer Science and Artificial Intelligence Laboratory and the Department of Electrical Engineering and Computer Science, and Hamilton Forsythe, an undergraduate researcher in the Department of Architecture at MIT.

<iframe title=”vimeo-player” src=”https://player.vimeo.com/video/465508515″ width=”640″ height=”360″ frameborder=”0″ allowfullscreen></iframe>

Fabric filament

Forman had been experimenting with 3D printing during the media arts and sciences class MAS.863 / 4.140 / 6.943 (How to Make (Almost) Anything), led by Professor Neil Gershenfeld, director of the MIT Center for Bits and Atoms. Forman’s experiments were inspired by the work of a friend from his undergraduate days at Carnegie Mellon University, who used under-extruded filament to produce vases. With his first attempts at under-extruding, “I was annoyed because the defects produced were perfect and periodic,” he says, “but then when I started playing with it, bending it and even stretching it, I was like, ‘whoa, wait, this is a textile. It looks like it, feels likes it, bends like it, and it prints really quickly.”

“I brought a small sample to my class for show and tell, not really thinking much of it, and Professor Gershenfeld saw it and he was excited about it,” Forman adds.

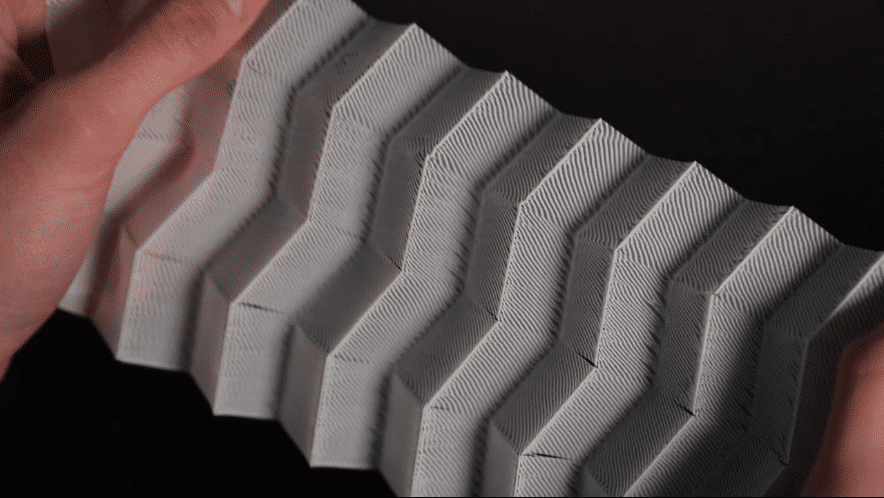

When the 3D printer extrudes the material, it will create periodic gaps in the deposited material. Using an inexpensive 3D printer for fused deposition modeling, Forman developed an under extrusion process called “spherical stretching” in which spheres of the thermoplastic polymer are connected by thin wires. This process produces a flexible, elastic textile with distinct warps and wefts similar to woven fabrics. Forman said it feels like a mesh jersey fabric.

“Not only are these textiles thinner and faster to print than other methods, but the complexity of the display form has also been improved. With this method, we can use an ordinary 3D printer to print 3D-sized enclosure forms without using special Slicer software.” “This is exciting because there are many opportunities for 3D printing fabric, but it is difficult to spread it easily because a lot of 3D uses expensive machinery and special software or special printer-specific commands.”

New textiles can be sewn, evacuated, and thermally bonded like ironed patches. Forman and his colleagues have used many common 3D printing materials to print textiles, including conductive filaments, which they use to make lamps that can light up and dim the lights by touching the pleats in the lampshade. The researchers suggest that other basic materials or additives can produce textiles with magnetic or optical properties, or by using algae, coffee grounds, or wood biodegradable textiles.

Scott Hudson, a professor at the Institute of Human-Computer Interaction at Carnegie Mellon University, said that Forman’s work is a very interesting addition to the expanding 3D printing technology.

“This work is particularly important because it functions within the same print process as more conventional techniques,” notes Hudson, who was not part of the study. “This will allow us to integrate custom 3D-printed textile components — components that can be flexible and soft – into objects, along with more conventional hard parts.”