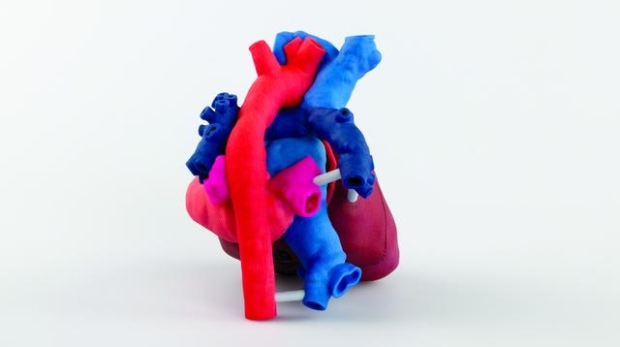

Harvard Wyss researchers develop 3D printing workflow to predict leaky heart valves Medical

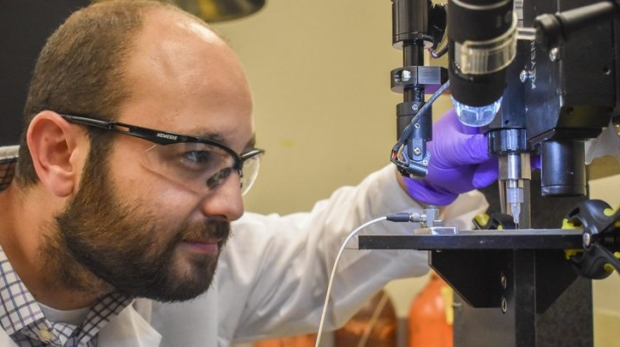

Researchers at the Wyss Institute for Biologically Inspired Engineering at Harvard University have created a novel 3D printing workflow that allows cardiologists to evaluate how different heart valve sizes will interact with each patient’s unique anatomy before the medical procedure is actually performed. The possibility of using material jetting 3D printing to produce more proficient implantable heart valves has been amply demonstrated. In this research project, the scientists also demonstrate that 3D printing can be used as a key tool to design even more accurate replacement valves, reducing time requirements on the operating table and improving the patient’s quality of life and recovery.