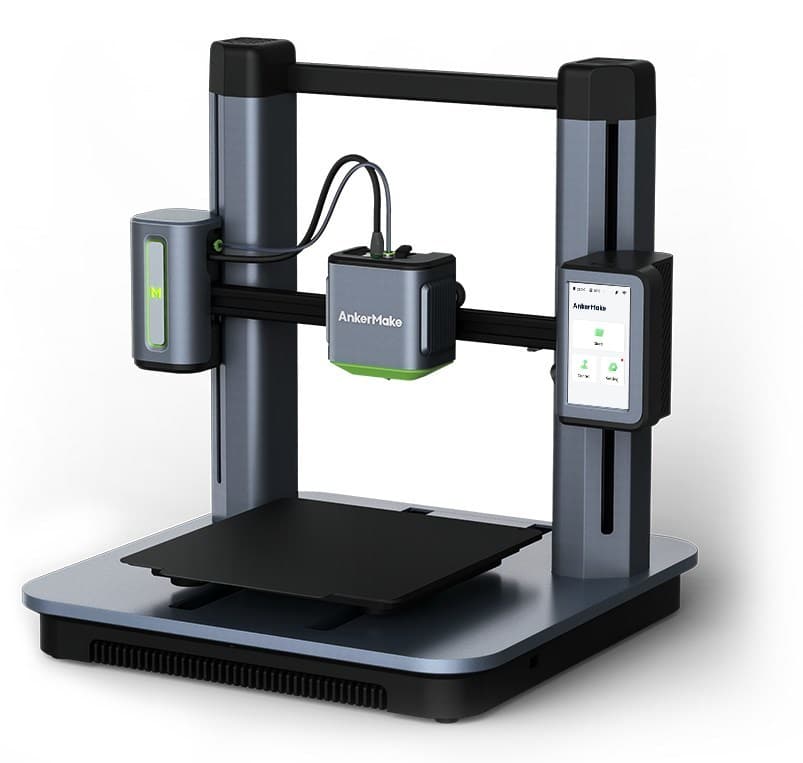

Anker Launches Crowdfunding for AnkerMake M5 3D Printer

AnkerMake, a new 3D printing brand from rapid charging accessories brand Anker, is introducing the AnkerMake M5, a 3D printer that, according to the company’s press release, was designed “to improve the user experience by reducing printing time up to 70%.” The 3D printer, which also promises several other welcome improvements on basic desktop models, is not yet available commercially but only via a Kickstarter campaign.