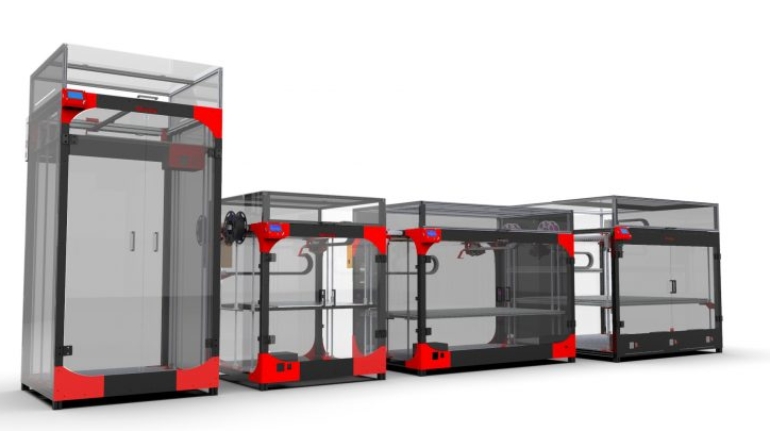

Argo 500 helps Roboze rise to the fore of large-scale, high-performance 3D printing 3D Printer Hardware

Italian 3D printing company Roboze has carved itself out an important place in the large-scale 3D printing market, largely thanks to its high-performance plastic printing capabilities. Since unveiling its large-format Argo 500 3D printer in 2017, the company has seen substantial growth and has continued on its journey of becoming a leader in the AM sector.