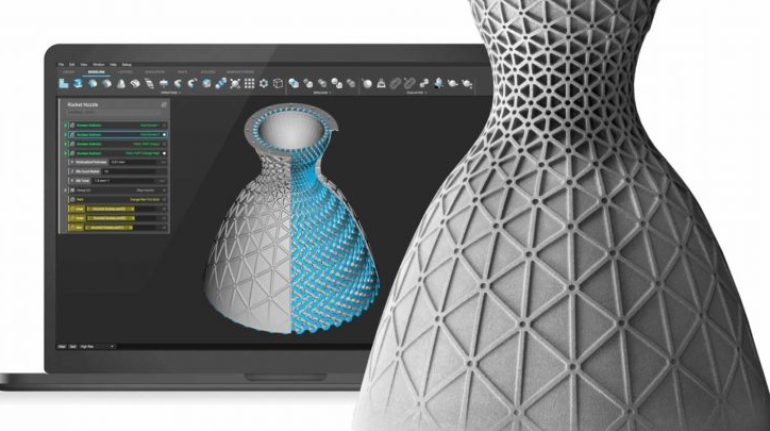

Splitvision improves medtech prototyping with Figure 4 3D printing 3D Printer Hardware

3D Systems recently revealed that Stockholm-based product design firm Splitvision Design was one of the first companies in the Nordic region to adopt its Figure 4 Standalone 3D printer. Since installing the scalable additive manufacturing solution, the Swedish agency has seen drastic improvements in its product development and prototyping processes—especially for products in the medtech sector.